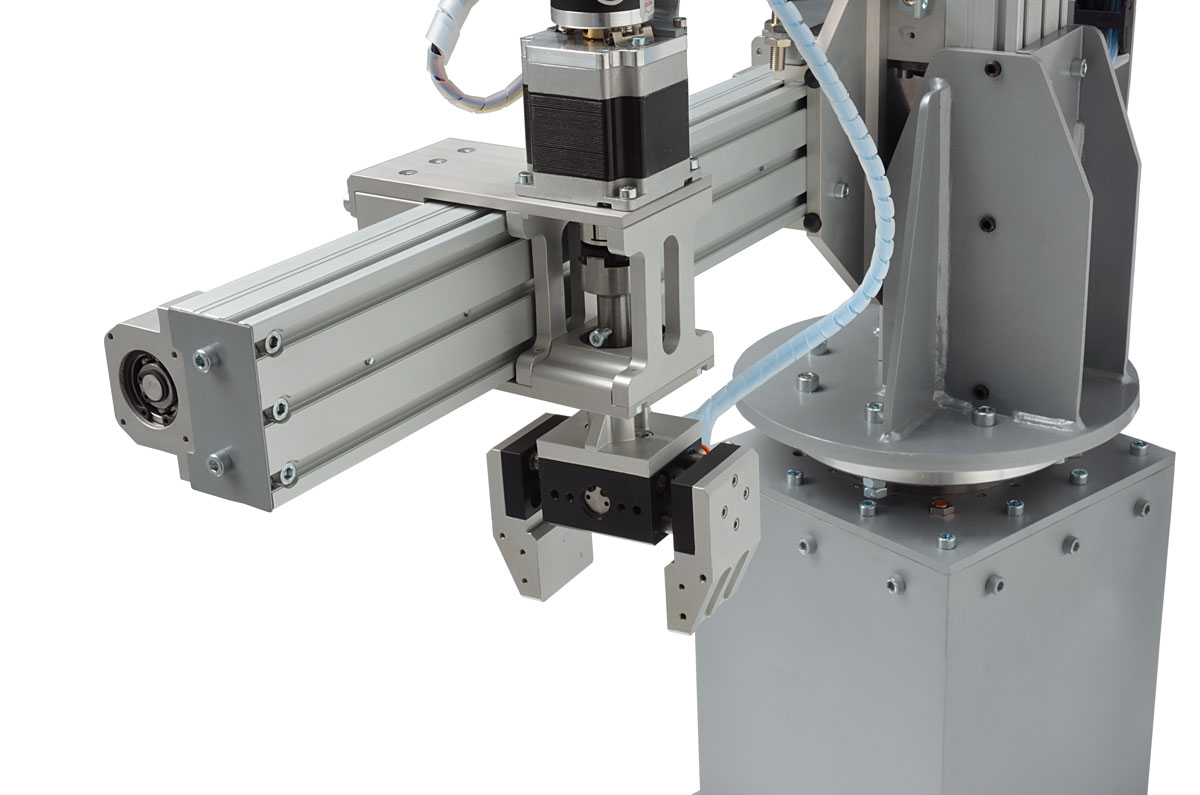

The TR300 Tower robot is designed for pick & place applications, packaging, palletizing, component assembly and sorting. It has 4 degrees of freedom allowing effective traffic implementation.

The robot arm allows you to mount any gripper, there is also the possibility of using a tool changer, which allows quick gripper replacement in manual or automatic mode.

The robot can carry loads with a total mass of up to 15 kg , with a maximum range of 500 mm (the standard range is 300 mm). In the mass to be transferred, take into account the weight of the gripper used in the application.

The proper assembly of the robot's wires allows you to achieve 360º movement around your own axis. The vertical axis of the robot can be additionally secured with a pleated cover against dirt.

|  |  |

The robot's construction can be adapted to its foundation on a running unit, based on linear guides and a high-precision slat bar drive. As a result, the robot gains additional movement, along which it can travel with the load, almost anywhere.

The robot can be additionally equipped with a variety of sensors or a vision system that transmits information on the location or orientation of the object to be transported.

Robot control is placed in a separate control cabinet Robot is programmed using the WBCprog environment installed on a PC computer with Windows system. To the robot controller, through the RS485 port, you can connect the HMI panel and communicate with it in the MODBUS-RTU protocol.

Technical data:

| Model robota | TR300-200-MLxx | |

| Rodzaj robota | Tower | |

| Liczba stopni swobody | 4 | |

| Zakres roboczy | J0 | 360º * |

| J1 | 200 mm** | |

| J2 | 300 mm** | |

| J3 | 360 | |

| Maksymalna prędkość | J0 | 360 /s *** |

| J1 | 1000 mm/s*** | |

| J2 | 1000 mm/s*** | |

| J3 | 360/s*** | |

| Rozdzielczość pozycjonowania | J0 | 0.1A ° |

| J1 | 0,01 mm | |

| J2 | 0,01 mm | |

| J3 | 0.1A ° | |

| Powtarzalność pozycjonowania | J0 | 0.1A ° |

| J1 | 0,05 mm | |

| J2 | 0,05 mm | |

| J3 | 0.1A ° | |

| Maksymalne obciążenie | 15 kg | |

| Kontroler robota | Dedykowany układ kontroli ruchu | |

| Sposób programowania | Za pośrednictwem komputera (RS232) | |

| Interfejs komunikacyjny | USB, RS485, uniwersalne We/Wy cyfrowe | |

| Zasilanie powietrzem | 4-5 barów | |

| Zasilanie | AC 380 V 50 Hz | |

| Temperatura pracy | 5-40°C | |

| * | w zależności od sposobu instalacji przewodów i wymagań klienta |

| ** | standardowy zakres ruchu, który może zostać zmodyfikowany zgodnie z wymaganiami klienta |

| *** | zależy od rodzaju przenoszonego obiektu i sposobu chwytu |

J0 - turn in the base

J1 - vertical axis

J2 - horizontal axis

J3 - rotation of the gripper