The high-performance surfaceCONTROL 3D 3200 snapshot sensor is ideal for use in industrial applications. Performsautomated inline 3D measurements to control geometry, shape and surfaces on surfaces reflecting diffuse light.

The sensor is characterized by a compact design and high measurement accuracy combined with high data processing speed. With high Z-axis repeatability of up to 0.6 µm, the sensor is ideal for precise 3D measurements and inspection tasks. Two different measuring ranges cover different measuring fields.

Properties

- Measurement time from 0.3 s

- Micron snapshots for large measurement fields

- Highest precision up to 0.4 μm

- Digital interfaces (integrated): GigE Vision /GenICam

- Digital interfaces (via 2D/3D Gateway): PROFINET / EtherCAT / EtherNet/IP*

- Digital inputs/outputs: 4 digital inputs/outputs for which parameters can be set (for external triggering, sensor control, sensor status output).

Precise 3D sensor for the smallest measurement objects

Thanks to its small measurement area of 30 x 18.5 mm, surfaceCONTROL 32x0-30 detects even the smallest 3D and surface structures with the highest precision and reliability. High resolution in the Z axis and precise repeatability enable high precision measurements. In addition, small objects can be detected with a working distance of 130 mm, and an XY resolution of 16 µm ensures even more accurate detection.

Measuring range increased by 240 mm with excellent precision in the Z axis

With a measurement area of up to 245 x 180 mm, surfaceCONTROL 35x0-240 captures structures and details on larger objects with high precision. Due to the large measuring range in the Z axis of 240 mm, these sensors are ideal for applications with large measuring volumes. The high Z-axis resolution of 5 µm combined with a larger measurement range ensures maximum precision in a wide range of applications, e.g. for testing bipolar plates for fuel cells.

The new generation of 3D measurements

In addition to fast data transmission, surfaceCONTROL 3D 3200 also has an IO interface. EtherNet/IP, PROFINET and EtherCAT are available through the use of 2D/3D Gateway II. Compatibility with 3D GigE Vision also enables easy integration with third-party imaging software. A comprehensive client software integration SDK completes the software package.

Application examples:

- 3D geometry inspection and shape detection

- Inspection of electronic components

- Automation, production and process monitoring and quality control

- Non-contact measurement of diffuse reflective surfaces in the Stop and Go process

- Shape, position and surface control

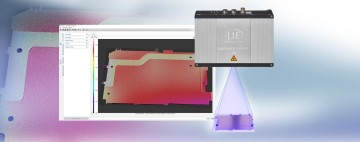

3DInspect software for 3D measurement and inspection tasks

3DInspect software is an advanced tool for setting sensor parameters and performing industrial measurements. This software transmits measurement data from the sensor via Ethernet and delivers it in three-dimensional form. This 3D data is further processed, analyzed and evaluated using 3DInspect measurement programs on a PC and, if necessary, recorded and transmitted via Ethernet to the control unit. If necessary, 3D data can be saved via software.

Furthermore, setting and configuration of the sensor is possible via software. When connected to an automation interface, the 3DInspect Automation software add-on features enable the use of SC3210 sensors, which also includes comprehensive data logging.