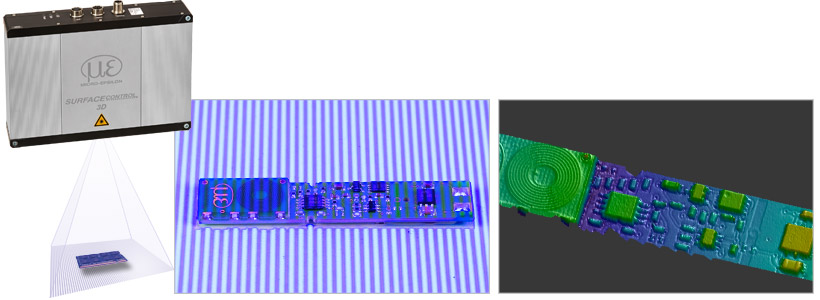

SurfaceCONTROL sensors are used for 3D measurements and surface inspection.The sensors use the principle of striped light projection to detect scattered light reflected from a surface and to generate a 3D point cloud.This point cloud is then assessed to recognize geometry, very small defects and discontinuities in the surface.

The offer includes sensors with various measurement fields.This enables the verification of the smallest details on elements, as well as shape deviations on large measuring surfaces.Powerful software packages for evaluation and parameter setting are available.

Features:

- Automated inline 3D measurement for geometry, shape and surface checks

- Continuous process monitoring

- Detection of various shape defects

- Objective evaluation of deviations

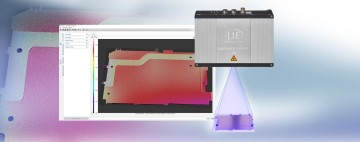

- Comprehensive SDK and evaluation software

- Easy integration with all popular 3D image processing packages

Software integration via Micro-Epsilon 3D SDK

SurfaceCONTROL sensors come with an easy-to-integrate SDK (Software Development Kit).The SDK is based on the industry standards GigE Vision and GenICam, covering the following function blocks:

- Network configuration and sensor connection

- Comprehensive sensor control

- Checking the transfer of measurement data (3D data, video images, ...)

- Management of user-defined parameter sets

- C / C ++ / C # library, sample programs and documentation

- Access to the sensor via GigE Vision is also possible without an SDK if you have GenICam compatible software.