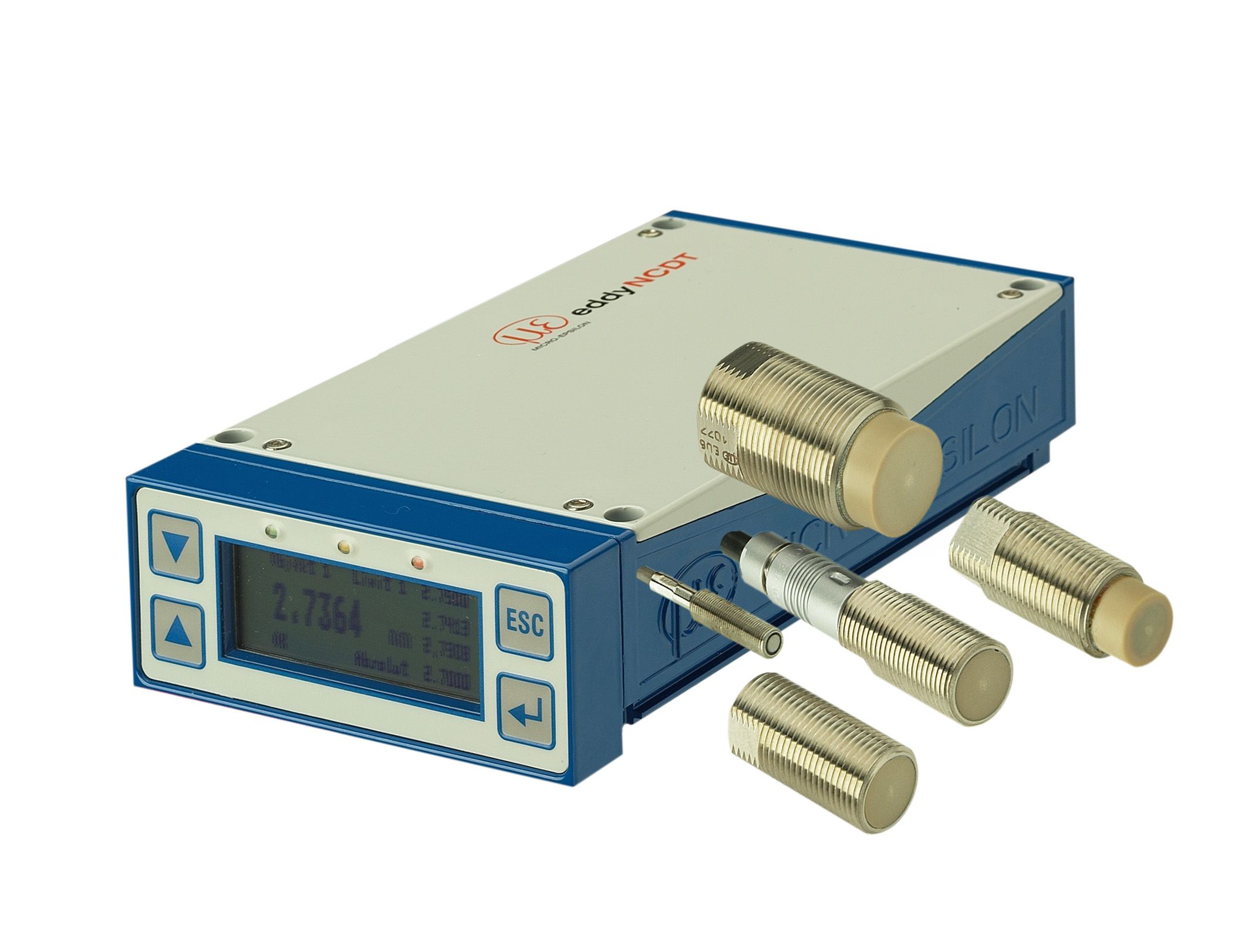

eddyNCDT 3300 is a system of multifunctional eddy current sensors. It is intended for industrial applications in factory automation, monitoring and inspection machines as well as measurements and tests. A new and modern controller. User-friendly.

Technical data:

- Measuring ranges (mm):

0.4 | 0.5 | 0.8 | 1 | 2 | 3 | 4 | 6 | 8 | 15 | 22 | 40 | 80 - Linearity max. 0.8ľm

- Resolution max. 0.02ľm

- Bandwidth up to 100kHz

- sensor temperature range: 50 50 to + 150 şC

- stability: <ą 0.15% of range şC

Advantages of contactless eddy current measurement :

- for use in all electrically conductive metals, with or without ferromagnetic properties

- small forms of construction

- measuring ranges 0.4-80 mm

- high resolution: 0.005%

- not sensitive to dirt, dust, moisture, oil, dielectric materials in the measuring gap

- resistant to interference in the electromagnetic environment

- wide range of operating temperatures

- high measuring accuracy, linearity 0.2%

Restrictions in applications:

- signal output and linearity depending on the electrical and magnetic properties of the measured object

- required individual linearization and calibration

- sensor cable length due to high resonator frequency limited to approx. 12-18 m

- The diameter of the sensor, and thus the diameter of the necessary object (measuring spot), grows with the measuring range

Applications

The eddy current sensors are suitable for the most stringent industrial conditions. In the automotive industry, in difficult conditions, they measure in a combustion engine on a test bench. The eddy current sensors in the miniature version in the ceramic housing are used in a high-pressure motor to measure the spin speed. The blower's turbine blower. Due to the high operating temperature and high rotational speed, it has not been possible to measure the turbine work correctly so far. EddyNCDT 3300 series eddy current sensors were used in difficult conditions of the production line to control the parallelism of the heavy production rollers.