The Nip Pressure Alignment Tool (NPAT) is a complete nip pressure and force measurement tool that takes the guesswork out of machine set-up. The NPAT is used to capture nip footprints and relative pressure distribution between nip rolls. The NPAT sensor band array can cover a very large area while utilizing one data acquisition handle.

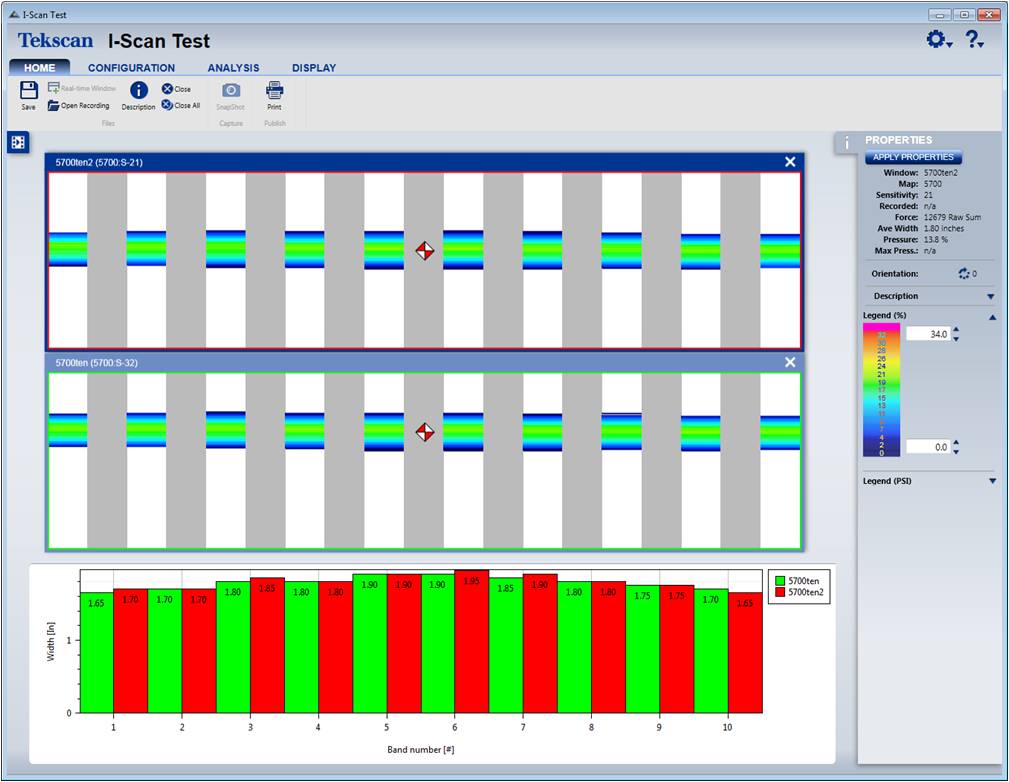

The system measures and clearly displays the results in real time, informing the user about the pressure distribution of the measured contact area of the rollers into the length and the width of the roll. Calculated data guarantee correctness of the production process, maintenance, quality control and proper roller settings.

Key features:

- Configurable sensor array

- Transporter for storing sensors and connecting to the correct position while using the system

- Housing that protects electronics in applications that require greater resistance to external conditions

- Sensors with electronics can be easily exchanged and serviced in the field

- Two sensor models that differ in their resolution, for measuring different roller diameters

- Easy folding for storage

Benefits of pressure measurement using NPAT:

- A clear presentation of the pressure distribution on the width and along the roll

- Ensures correct positioning of rollers

- Protects the machine and the product from damage

- Provides countable and reliable data

- More effective maintenance

|  |

| Appliacation example of NPAT system | Exemplary window of NPAT system software |

Software showing roll misalighment. | Software showing heavy crown or misalighment. |

NPAT system replaces previously available NPMS system.

Check out this short video to see how NPAT system work.