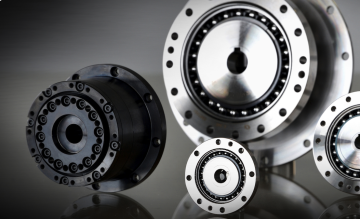

Compact, precision gears with zero backlash

Excellent quality harmonic/wave gears with zero backlash

Wave gears, or harmonic gears, are characterized by a complete lack of backlash, exceptional repeatability and high torque - all in a compact and lightweight design. They are developed taking into account the customer's exact requirements and individual needs. Production complies with the standards applicable in the automotive industry, which guarantees the highest quality, large quantities, short lead time and a high level of profitability.

Principle of operation of harmonic gear

Wave gears consist of only three elements: a wave generator, a flexible ring and a circular (rigid) ring. They are characterized by power transmission via an elastic element (spline). It is a flexible, cylindrical steel element with external gear teeth that takes on an elliptical shape when the wave generator is inserted. Combined with the constantly rotating engagement of the flexible ring teeth and the round ring teeth, this ensures absolutely no backlash, exceptional gearing accuracy and high torsional rigidity.

Three components:

- Gear ring: cylindrical rigid ring with internal gear teeth

- Flexible ring: a cylindrical, flexible, thin-walled steel member with external gear teeth

- Wave generator: a hub with an elliptical external contour on which a special, radially flexible ball bearing is mounted.

How does wave gear work?

From the video below you will learn more about the principle of operation, construction and characteristics of one of the most precise and backlash-free types of gears.

Our offer

Sizes from 35 to 102, with gear ratios i = 30-160:

- Gear sets: the simplest variant of the wave gear

- Gear kits plus: ready to install, including rigid output shaft bearing

- Gears: Fully enclosed, including rigid output shaft bearing and seal system - plug-and-play variant

- Actuators

- Individual, non-standard solutions

- Complete, precise electromechanical systems

All gears are available as:

- Gears with solid and hollow shaft

- Hat Gears (HTG) and Cup Gears (CTG)

Hat Gears (HTG) and Cup Gears (CTG) różnią się jedynie konstrukcją elastycznego wielowypustu. Obie wersje są dostępne z wałem drążonym i wałem pełnym. Główną zaletą przekładni typu Hat jest większy wał drążony, podczas gdy przekładnia typu Cup ma wyższą przeciążalność.

Custom designed wave gears

Nabtesco (OVALO) develops and implements non-standard wave gears for mass production. Our focus is on maximum performance, innovative technologies and compact design - whether in the standard version, custom adaptation or fully integrated solution.

The gearboxes are based on a flexible modular product system, with a large selection of sizes, versions and additional components such as bearings, shafts, seals, housings, sensors and ECUs. It is also possible to adjust gear properties such as reverse torque, overload resistance, gear accuracy and main bearings.

Applications

Innovative solutions and technologies from Nabtesco (Ovalo) meet the most stringent standards and are used wherever maximum precision, efficiency and reliability are required. In addition to torque, we take stiffness and hollow shaft diameter into account when designing wave gears to guarantee optimal performance.

Areas of application:

- Robotics (industrial robots and cobots)

- Automation

- General mechanical engineering

- Machine tools, CNC machines

- Medical technology

- Service

- Automated guided vehicles

Do you have any questions or need an individual consultation?