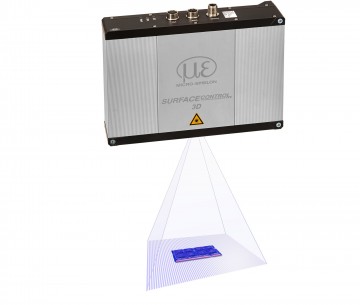

The high-precision SurfaceCONTROL 3D 3500 is a 3D striped light sensor that is ideally suited for the automated measurement of geometry, shape and surface on diffuse reflective surfaces.

SurfaceCONTROL 3D 3500 is distinguished by its compact design and high measurement accuracy combined with high data processing speed.The two models include different measuring fields.

In addition to fast data transfer via Gigabit Ethernet, the sensor offers an additional digital I / O interface.

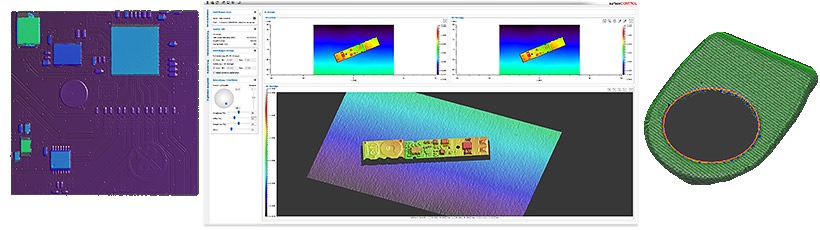

2D / 3D Gateway II supports EtherNet / IP, PROFINET and EtherCAT connections.Advanced software tools allow precise 3D measurements and surface inspections.GigE Vision compatibility also allows easy integration with third-party imaging software.A comprehensive SDK for client software integration completes the software package.

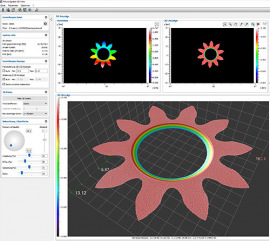

Examples of surfaceCONTROL 3D 3500 application:

- 3D geometry check and shape detection

- Inspection of electronic components

- Defect detection

- 3D text recognition and detection of the finest structures

Properties of surfaceCONTROL 3D 3500:

- Full 3D images in 0.2 seconds

- Micrometric accuracy snapshots with large measuring fields

- Highest precision down to <0.4 μm

- Up to 2.2 million 3D points per second

- Digital interfaces (integrated): GigE Vision / GenICam

- Digital interfaces (via 2D / 3D gateway): PROFINET / EtherCAT / EtherNet / IP

- Digital inputs / outputs: 4 digital inputs / outputs for which parameters can be set (for external trigger, sensor control, sensor status outputs)

The evaluations from 3DInspect can be transferred to the PLC via these interfaces.Sensor settings can be loaded by the controller via 3DInspect using parameter set mapping.

3DInspect software for 3D measuring and inspection tasks

3DInspect software is an advanced tool for setting sensor parameters and measuring tasks in industry.This software transfers the measurement data from the sensor via Ethernet and provides it in three-dimensional form.This 3D data is further processed and evaluated using the 3DInspect measuring programs on the computer.

If necessary, they are also registered and sent via Ethernet to the control unit.If necessary, 3D data can be saved with the software.In addition, kconfiguration of the sensor is possible via software.

3D-View software for 3D visualization

3D View software 3D-View software offers a convenient user interface for surfaceCONTROL sensors.This easy-to-use software enables quick commissioning and calibration of the sensor.It offers configuration and optimization of parameters and ensures correct positioning of the measured object and sensor.The software can also be used to start data acquisition.

3D View software 3D-View software offers a convenient user interface for surfaceCONTROL sensors.This easy-to-use software enables quick commissioning and calibration of the sensor.It offers configuration and optimization of parameters and ensures correct positioning of the measured object and sensor.The software can also be used to start data acquisition.

It visualizes the obtained 3D data and exports it in various file formats (ASCII, CSV, STL, PLY) for further processing.3D-View software is especially useful for system integrators as it provides important information.

It gives them access to all GenICam parameters, which greatly simplifies software integration.For inline applications, the display of the measurement duration allows conclusions to be drawn about the cycle time.

.jpg)