Clamps for linear guides are often implemented in machines and a variety of systems, mostly to ensure safety. However, they can also be used for decelerating different masses or for precise positioning. AND

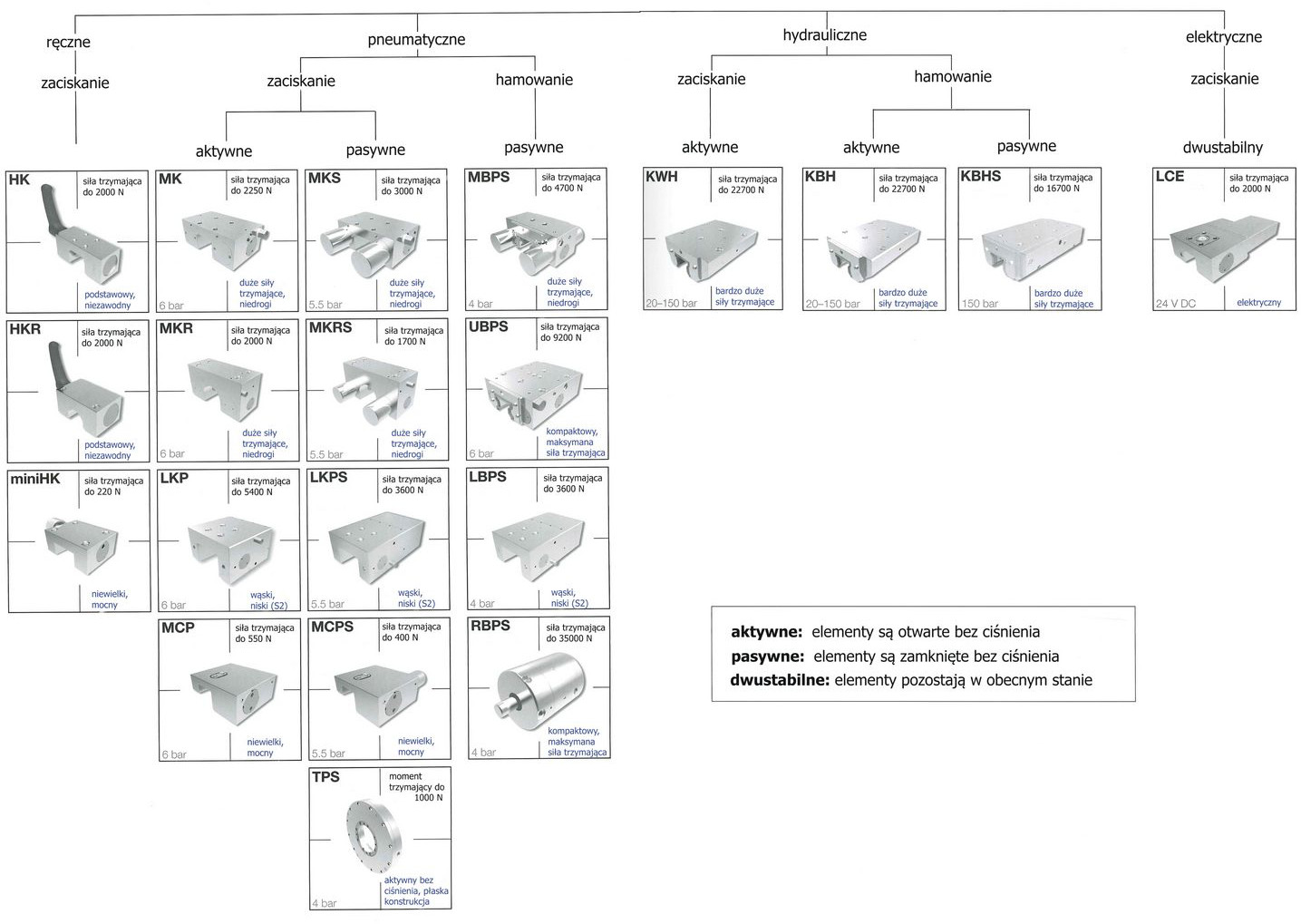

The simplest technical solutions are manual clamps. Three series of products are available for use on standard, miniature and prism guides. The tightening takes place by means of a lever.

The compressive elements are symmetrically clamped or on the rail or around the guide axis (depending on the series), which ensures an even distribution of the forces. This type of terminal is a very good solution in all applications where there is no need for immediate braking and operation, but the precise fastening is key.

In the case of larger systems and machines that use oil in their design, the practical solution is a hydraulic clamps and braking elements. Thanks to the large contact surface (covered with a special braking lining), these elements allow for obtaining a lot of axle rigidity. The oil operated via a piston mechanism on the rail. The compressor provides preloading of the system and the pressure diaphragm technology guarantees certainty.

The classic elements of the Zimmer production pockets are pneumatic clamps and braking elements . They are primarily characterized by a compact and robust housing and withstanding high pressure forces, as well as precise clamping. The extensive builders' experience has enabled the development of several series of products tailored to a variety of applications.

Electric way to generate clamping force using LCE series clamps. The clamps in this series allow you to open or close by applying voltage. They can be used in machines where there is a need to automatically block an element, and they do not have hydraulic or pneumatic systems. The LCE series clamps can also be used to protect components in the event of pressure loss in hydraulic / pneumatic systems.