Drives and control

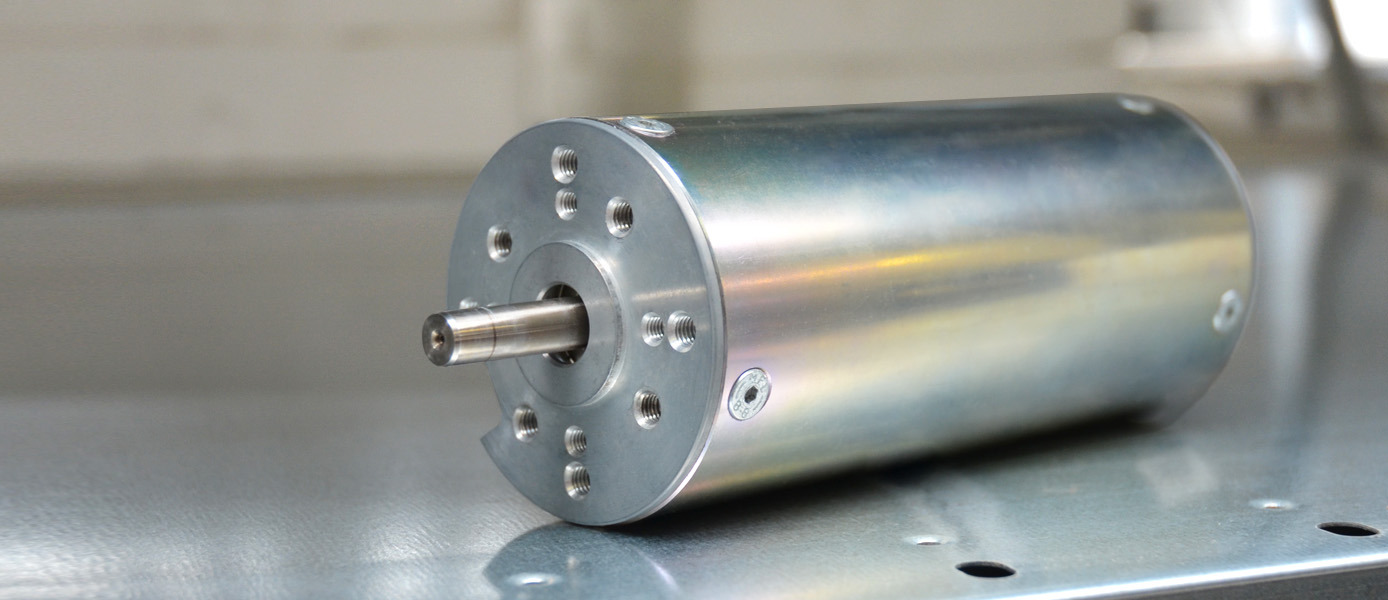

Today it is difficult to imagine the world of technology and machines without electric motors. DC motors are an inseparable element of a variety of machines and systems in every industry. They serve as a drive for production lines, starting pumps, vanes, etc. Classic brush DC motors are inexpensive and very functional drives, characterized by simple control.

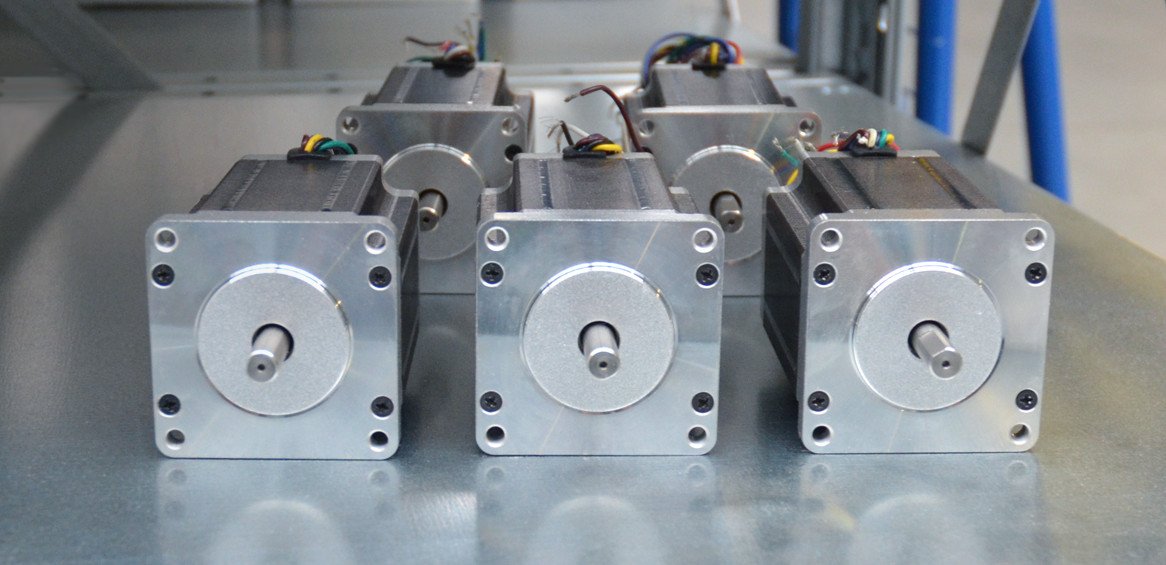

In applications where positioning accuracy is crucial, but rotational speed does not play a big role, stepper motors are most often used.

The positioning precision of the stepper motor can be further increased by using a suitable stepper motor driver and equipping it with an encoder.

Due to the growing need for energy-saving drives, brushless DC motors are gaining popularity. They are characterized by higher efficiency, which remains constant in a large load range, and they can also achieve high angular acceleration of the rotor. BLDC motors, thanks to electronic commutation, are characterized by long life and stable operation.

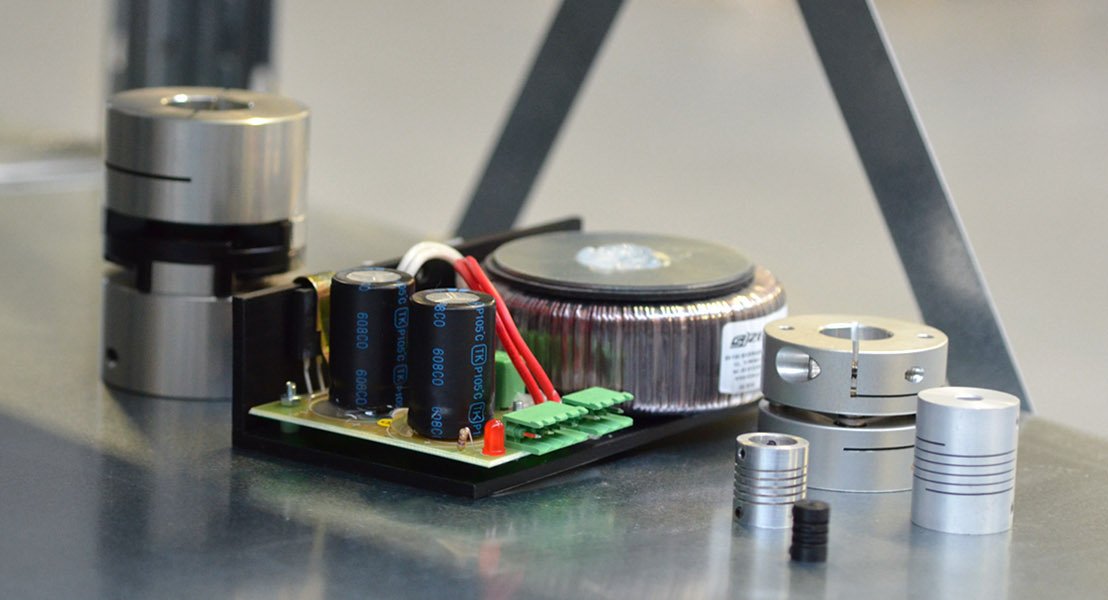

To control these drives, WObit offers advanced drivers with interfaces such as EtherCAT, Profinet or CANopen. Brushless motors with integrated commutation and control electronics are also available with a modular, decentralized control topology.

A specific type of electric motors that allows you to adjust the angular position of the motor shaft, rotational speed and acceleration is the servo motor. It is a motor, usually brushless, which is additionally equipped with an encoder for positioning. Servo drives are used in applications that require high dynamics, efficiency and good control properties.

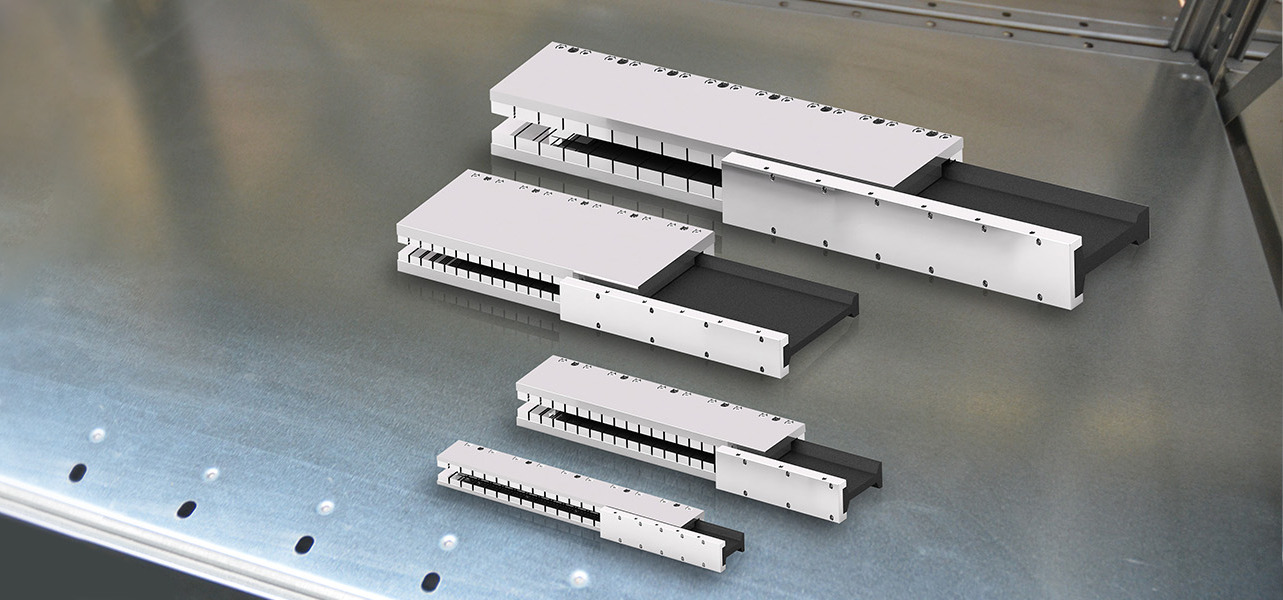

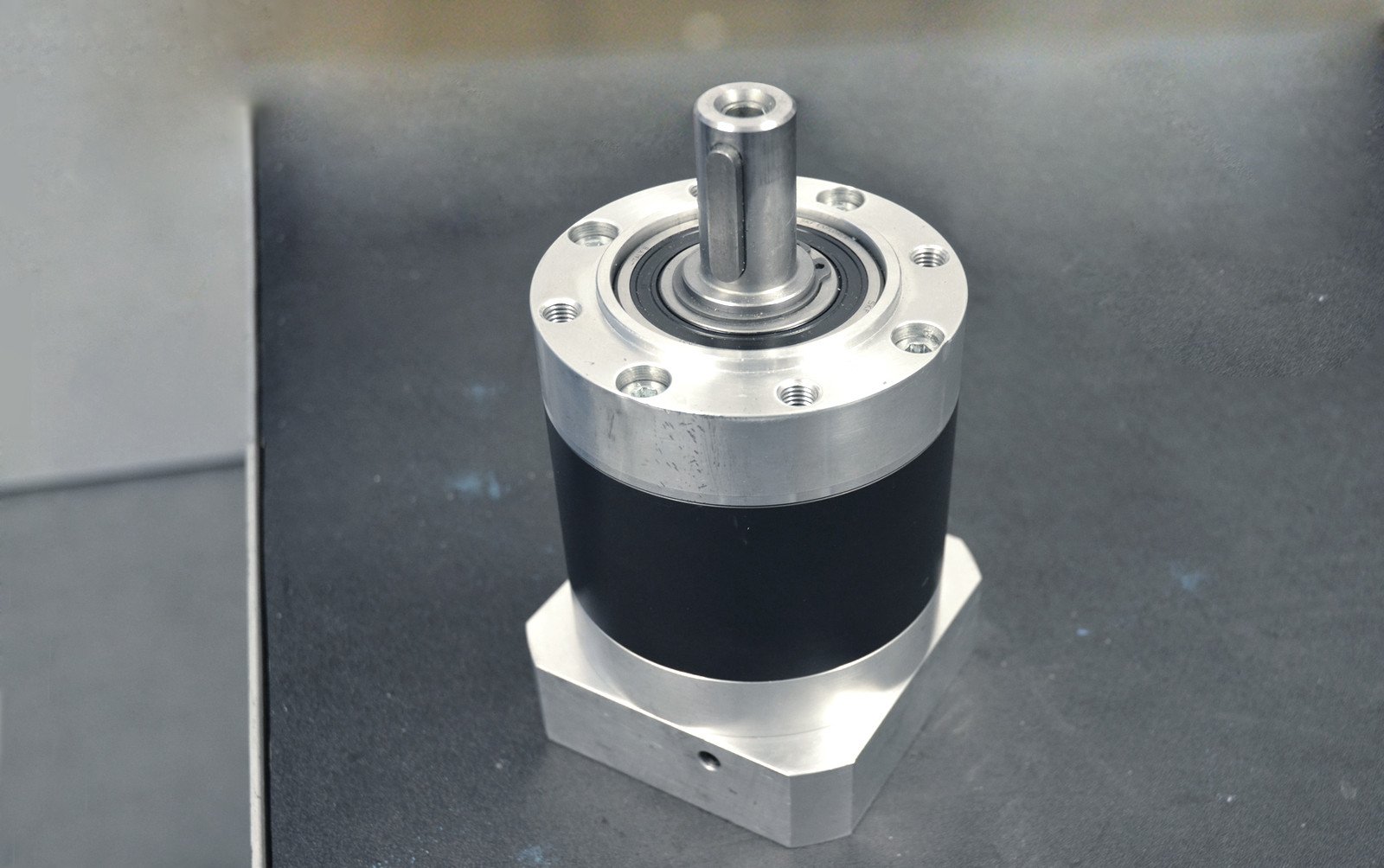

A wide selection of planetary and cycloidal gearsas well as accessories such as power supplies, clutches and fasteners are available for the drives.