Mechanics

The production of machinery and heavy equipment requires precise and durable components that ensure optimal repeatability and durability of the designed structure. For this reason, such mechanical elements aslinear guides, ball screws, clampsor bearing blocks have long been an important part of the WObit company's offer.

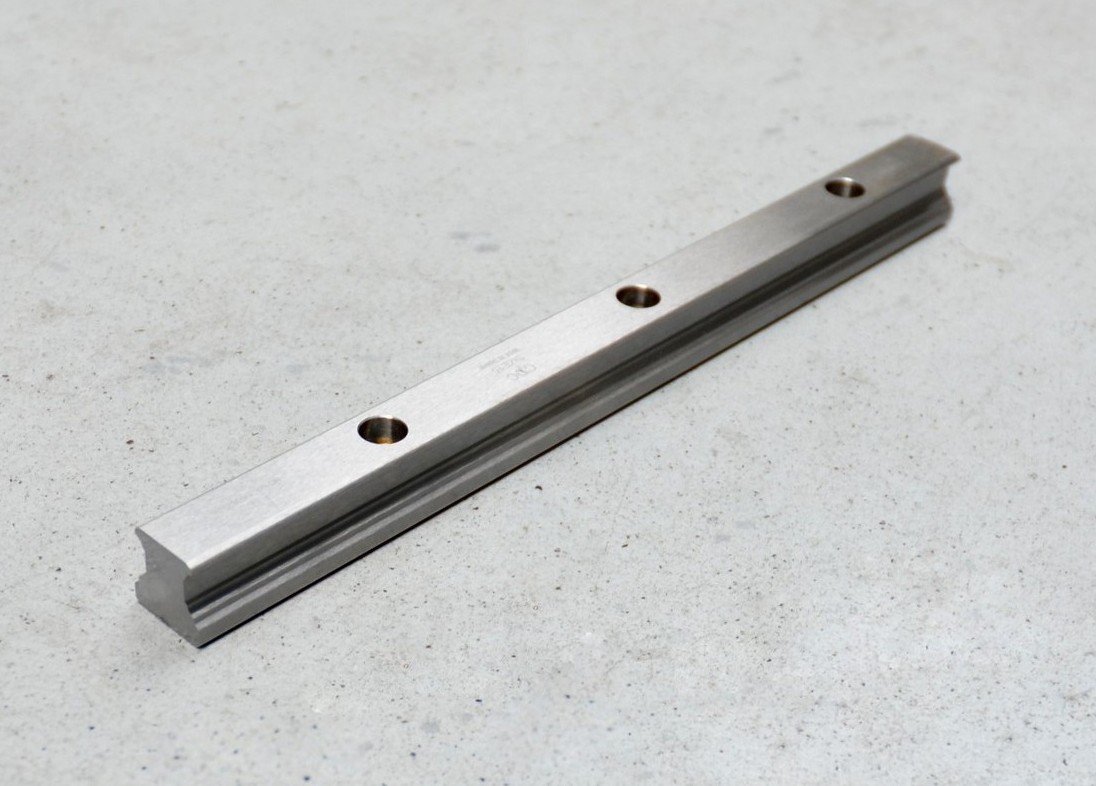

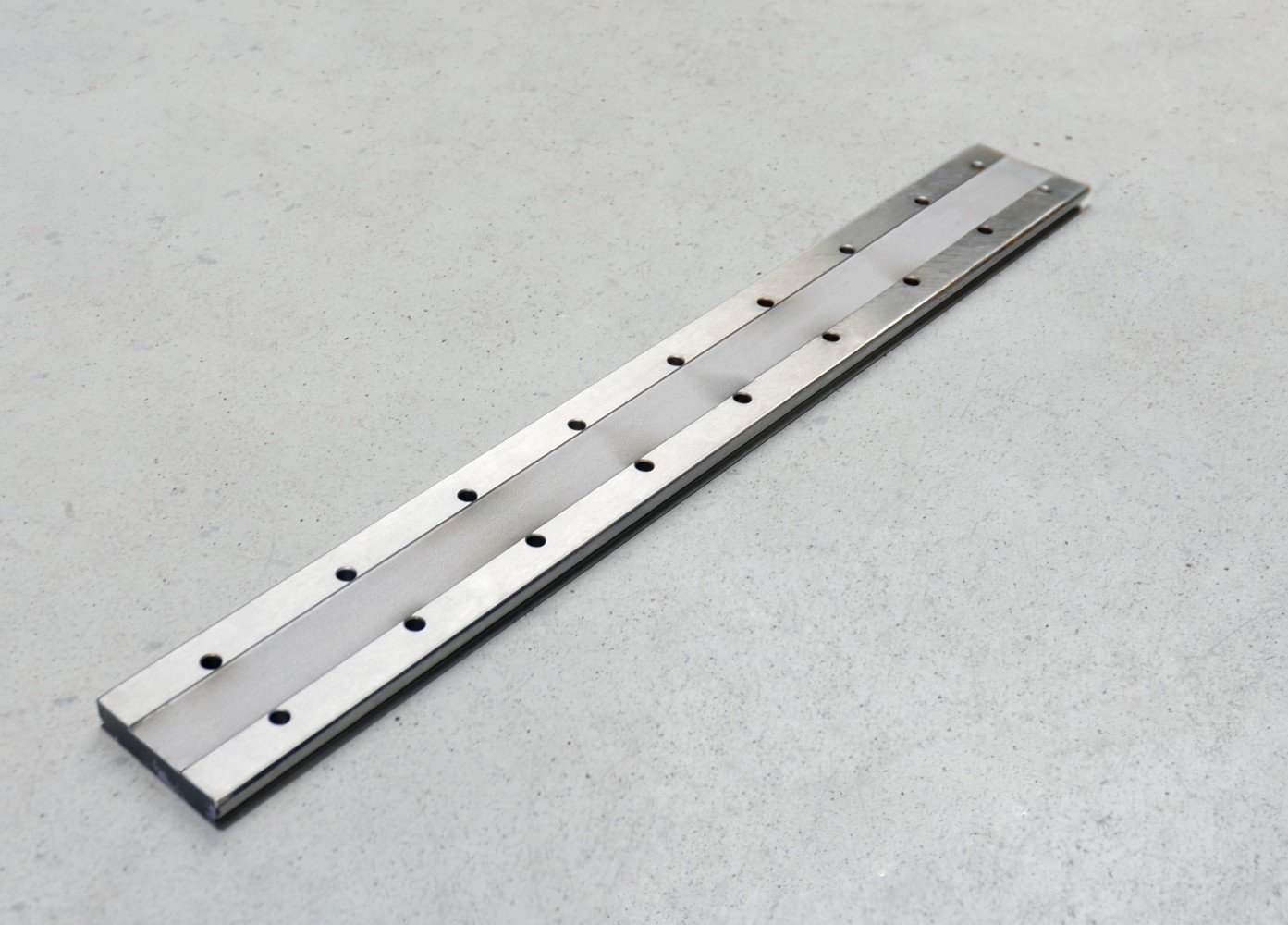

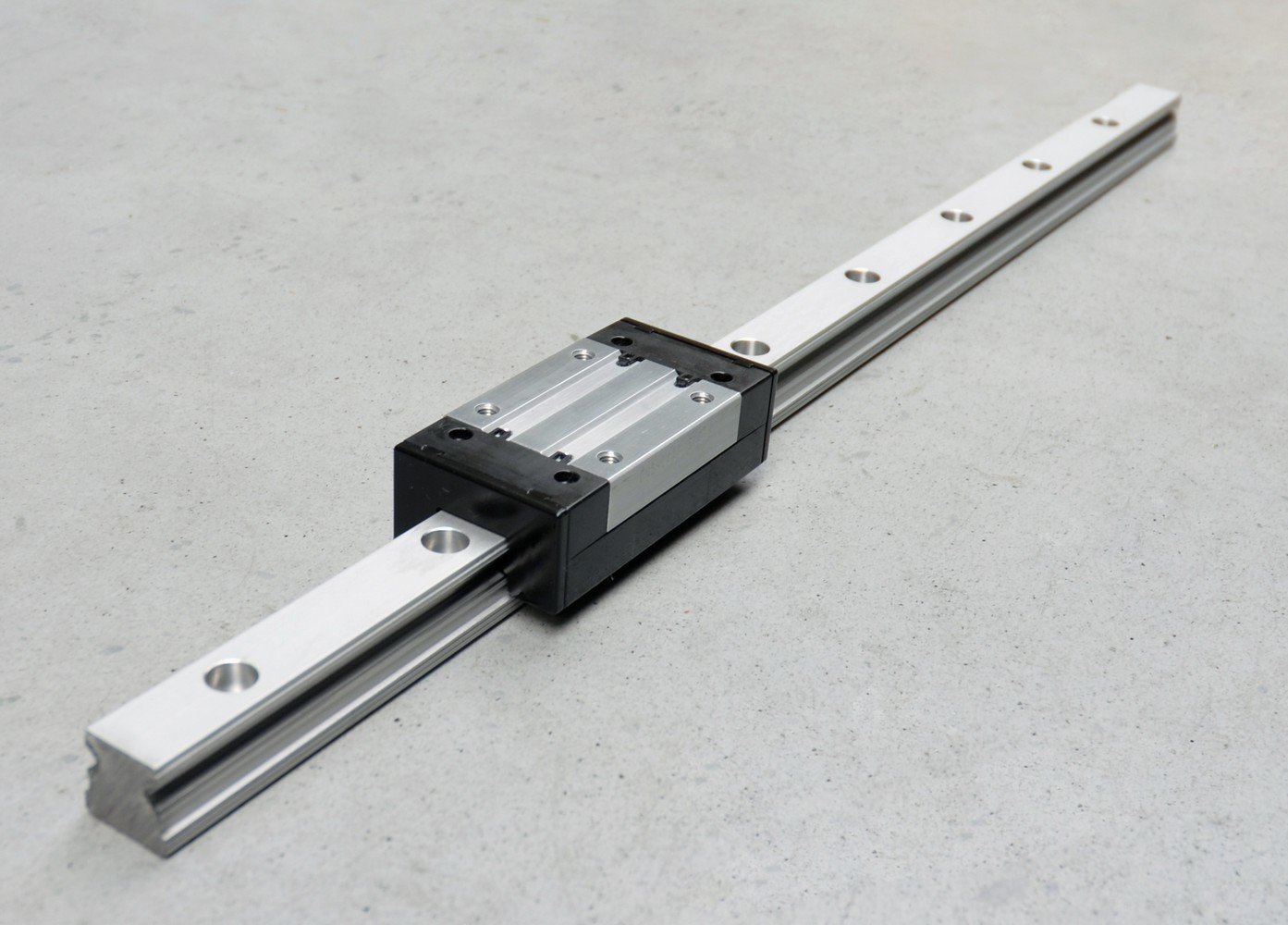

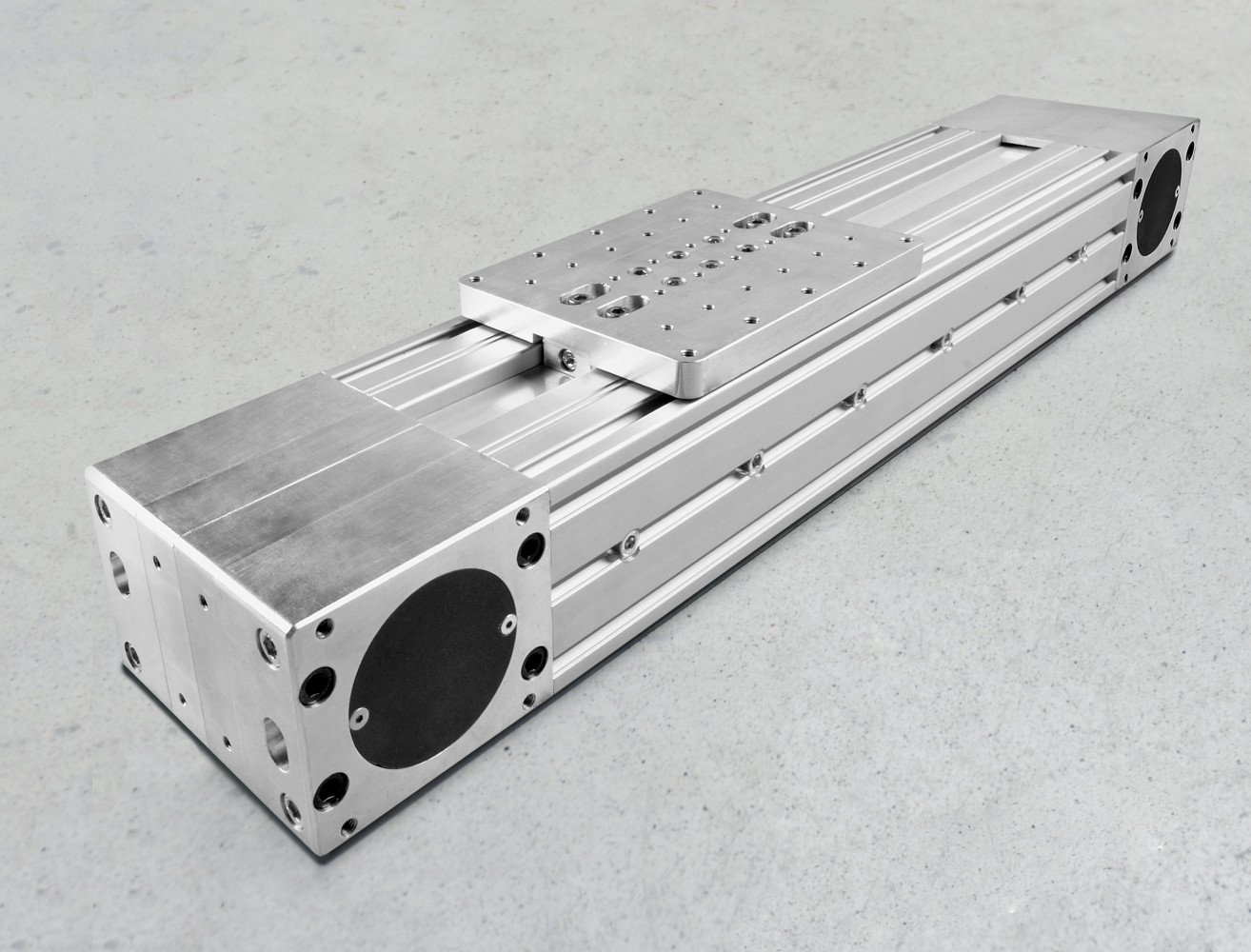

Linear guides are the most commonly used for longitudinal movement, which are characterized by a relatively low price, high durability and repeatability. The guides from the WObit offer are available in five accuracy classes, ranging from super precise to normal and can be made of stainless steel, while in the case of miniature versions it is standard.

The devices inherent in linear guides, used to ensure safety, especially in multi-axis systems or vertical applications, are calipers and brakes. When selecting them, it is extremely important to pay attention to the quality of materials and workmanship, as well as the no less important method of power supply. The WObit company offers various models of calipers and brakes operating in manual, pneumatic, hydraulic and electric technology.

Clamps are suitable for all types and types of guides and prepared for each size of linear and bar guides. Their use in the positioning of linear axes allows for high accuracy as well as elimination of backlash, and the compact design facilitates installation, even in small, hard-to-reach spaces.

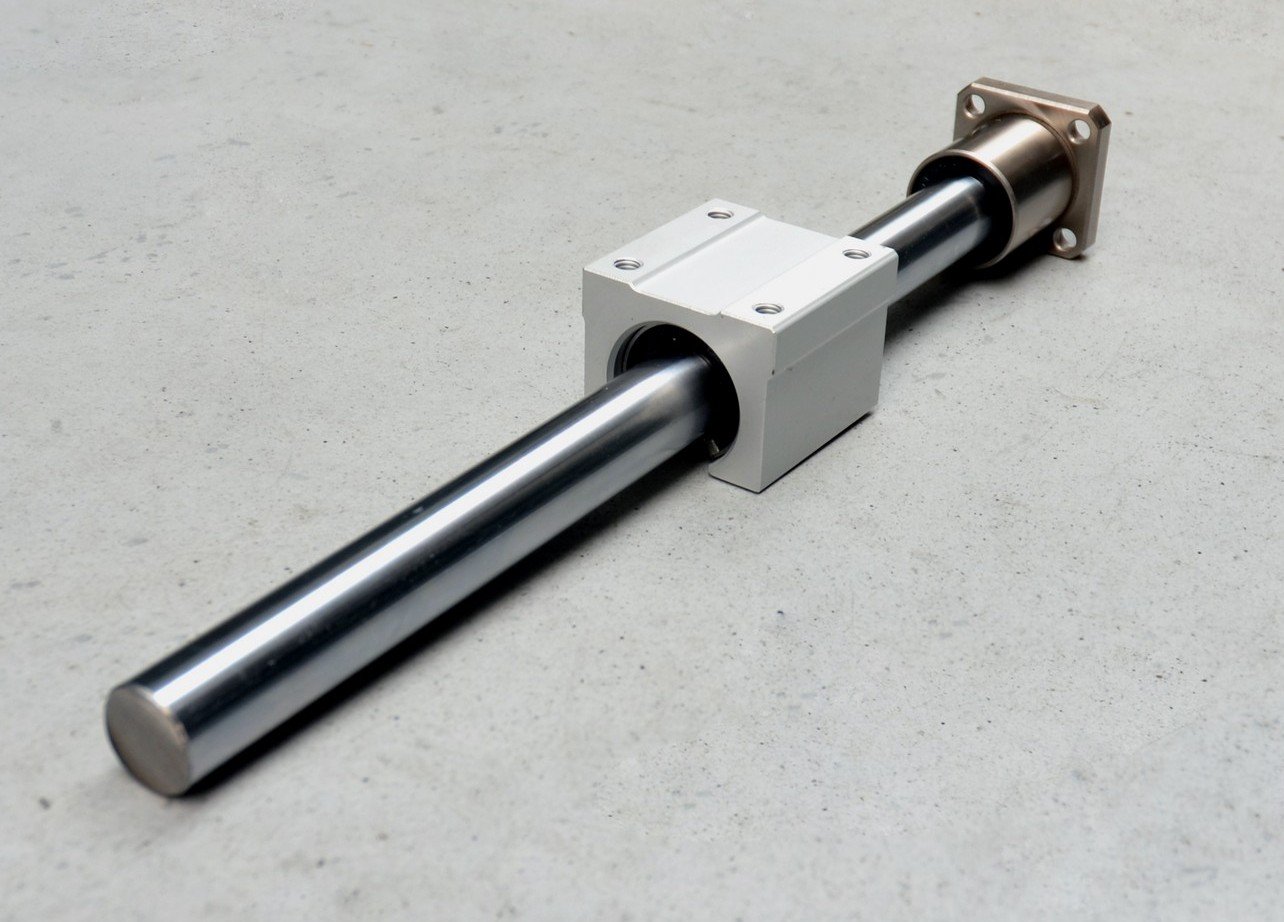

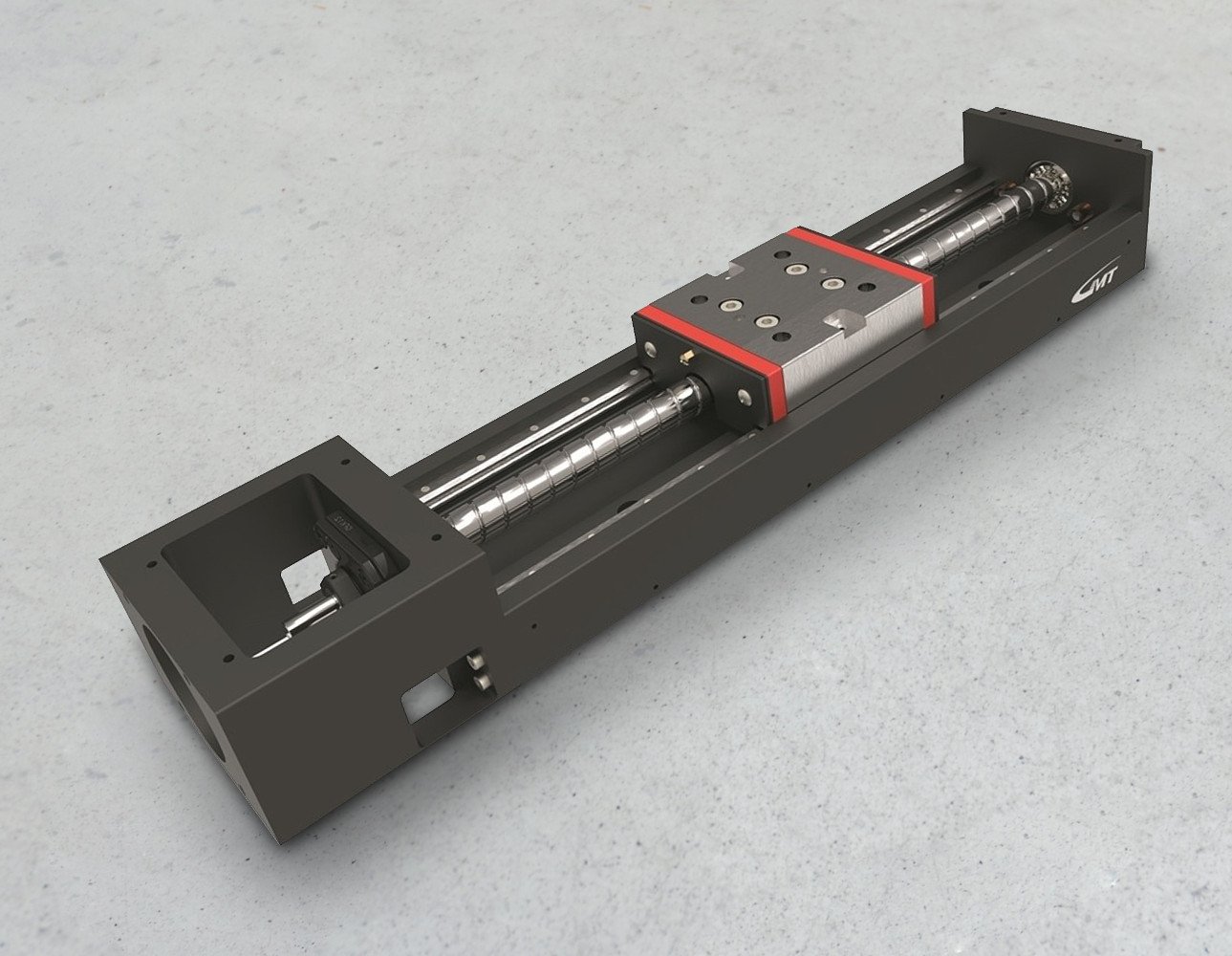

Ball screws are most often used to move large masses and ensure high positioning precision. Precision rolled screws are available in accuracy classes C5 and C7, with diameters from 6 to 80 mm and a pitch from 1 to 50 mm.

A wide range of nuts is available for each screw, depending on the requirements of the application. The nuts are available with an external circulation, which is an economical solution for a smoother ball travel, and also with an internal circulation where the outer diameter of the nut has been significantly reduced.

In addition to the bolt and nut, it is also important to select the correct mounting components, such as bearing blocks, to ensure precise and rigid guidance. Thanks to the bearings mounted in the blocks, it is possible to transfer complex radial and axial loads in all directions.

Another solution for moving large masses, with high positioning precision, and at the same time ensuring a speed of up to 11 m / sec. are precision toothed guides.