Precise linear movement is essential in many mechatronic systems, machines, and measuring stations. The selection of appropriate components can be time-consuming, but here ready-made systems such as MLA linear modules from WObit come to the rescue.

Linear modules are comprehensive mechatronic solutions from WObit that enable the implementation of linear displacements. The modules are built based on special profiles made of aluminum alloy, ensuring good strength properties at a relatively low weight. The family of linear modules consists of several design solutions, in which you can choose the module length, drive, control, additional sensors, and mounting accessories.

The most popular MLA module is built on an aluminum profile intended for it and a guide with a profile rail on which the slide rolls and the drive is transmitted through a toothed belt. In the standard version, it is driven by a stepper motor, which enables open-loop control (without the need for a second position sensor). At the customer's request, the MLA module can be equipped with a DC motor, BLDC motor, servo, or a crank enabling manual control. This module is suitable for standard applications requiring dynamic linear motion with light loads.

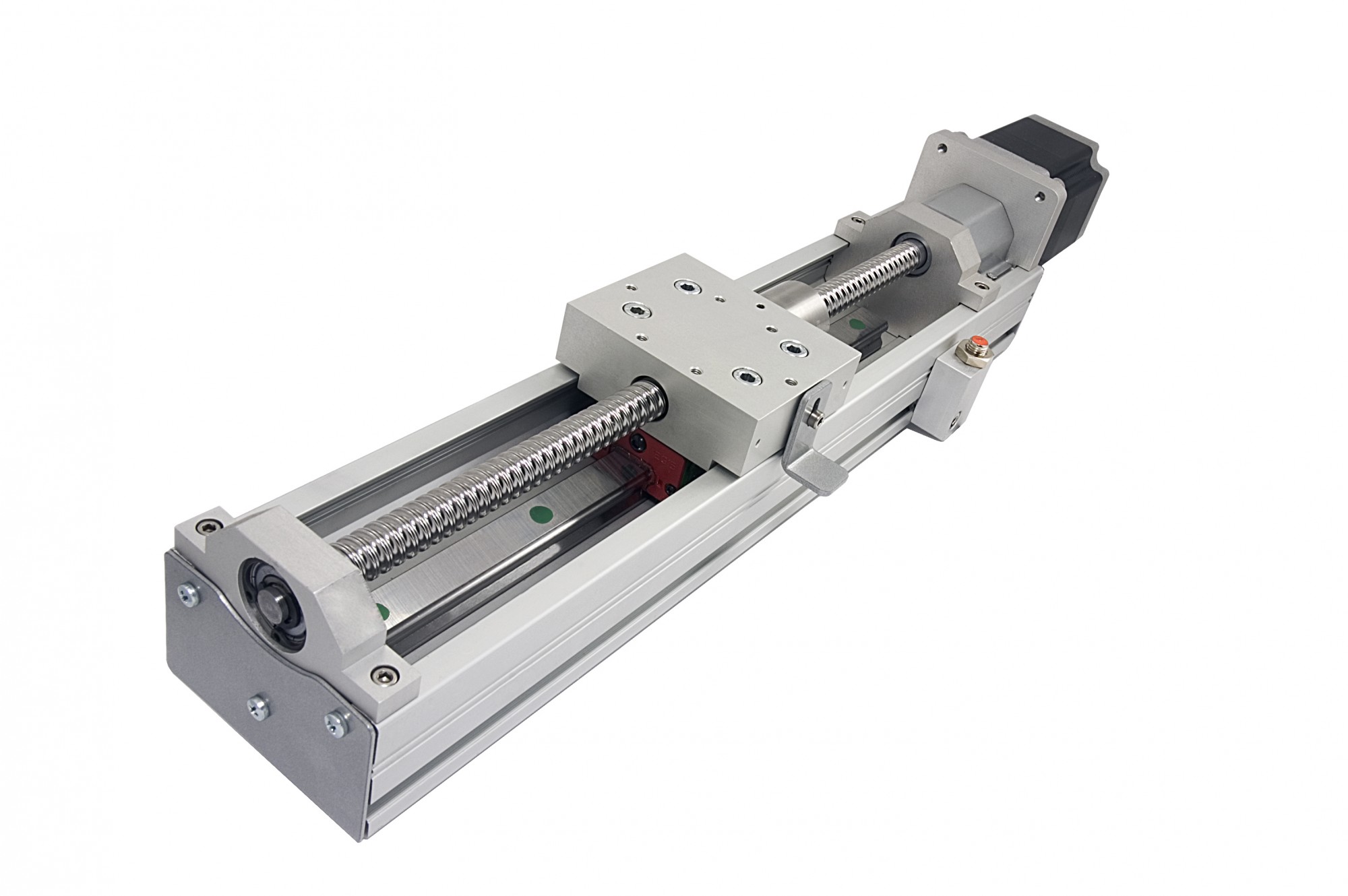

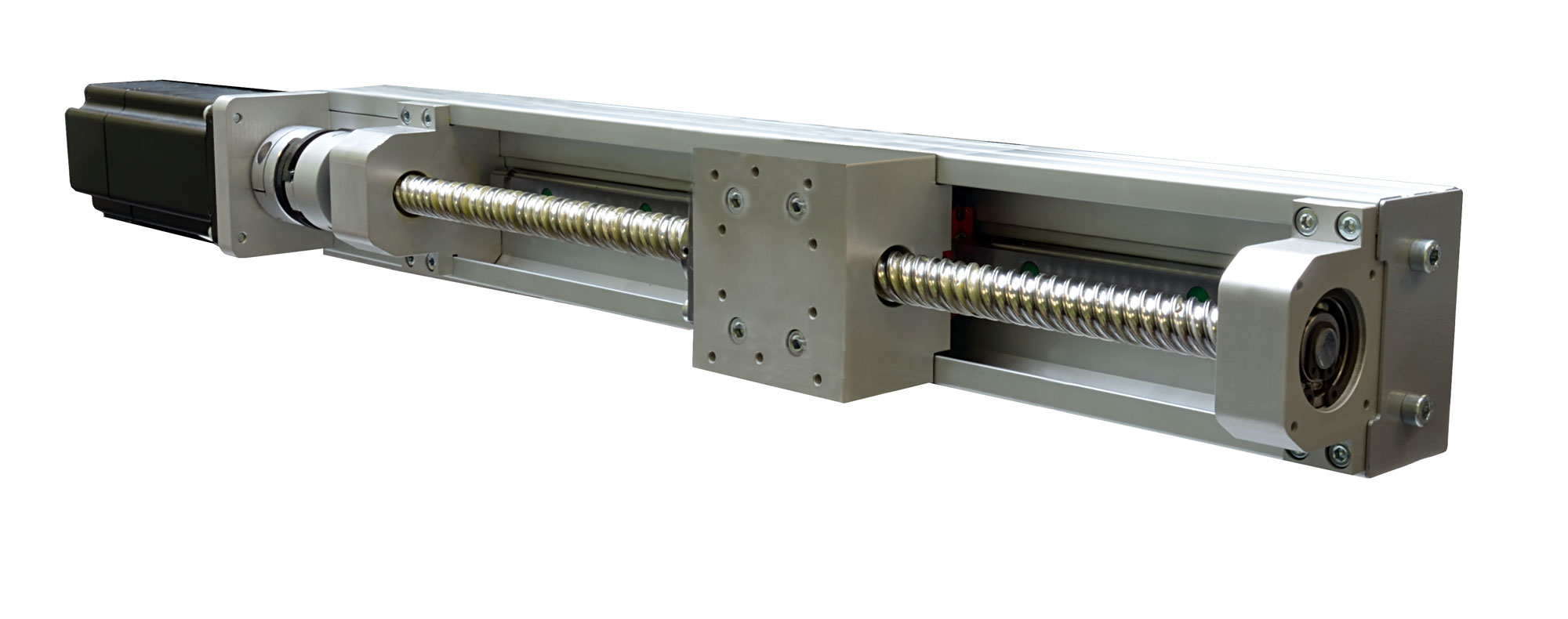

In applications requiring higher precision, MLAS linear modules are more often used, the structure of which consists of an aluminum profile, linear guide, and a ball screw. The use of a ball screw allows for the transfer of very high axial forces (up to 1000 N) and ensures considerable precision of movement, enabling positioning with an accuracy of hundredths of an mm. Like the toothed belt version, MLAS can use a stepper motor, a DC motor, a BLDC motor, and a servo drive.

Longer working range and high tightness

For transferring larger loads in the working range up to 1 m, WObit specialists have prepared MLAS16 and MLA2P modules.The MLAS16 module is driven by a Ø15 or Ø16 ball screw.The positioning repeatability is 0.01 mm, and the maximum axial force is 1000 N.

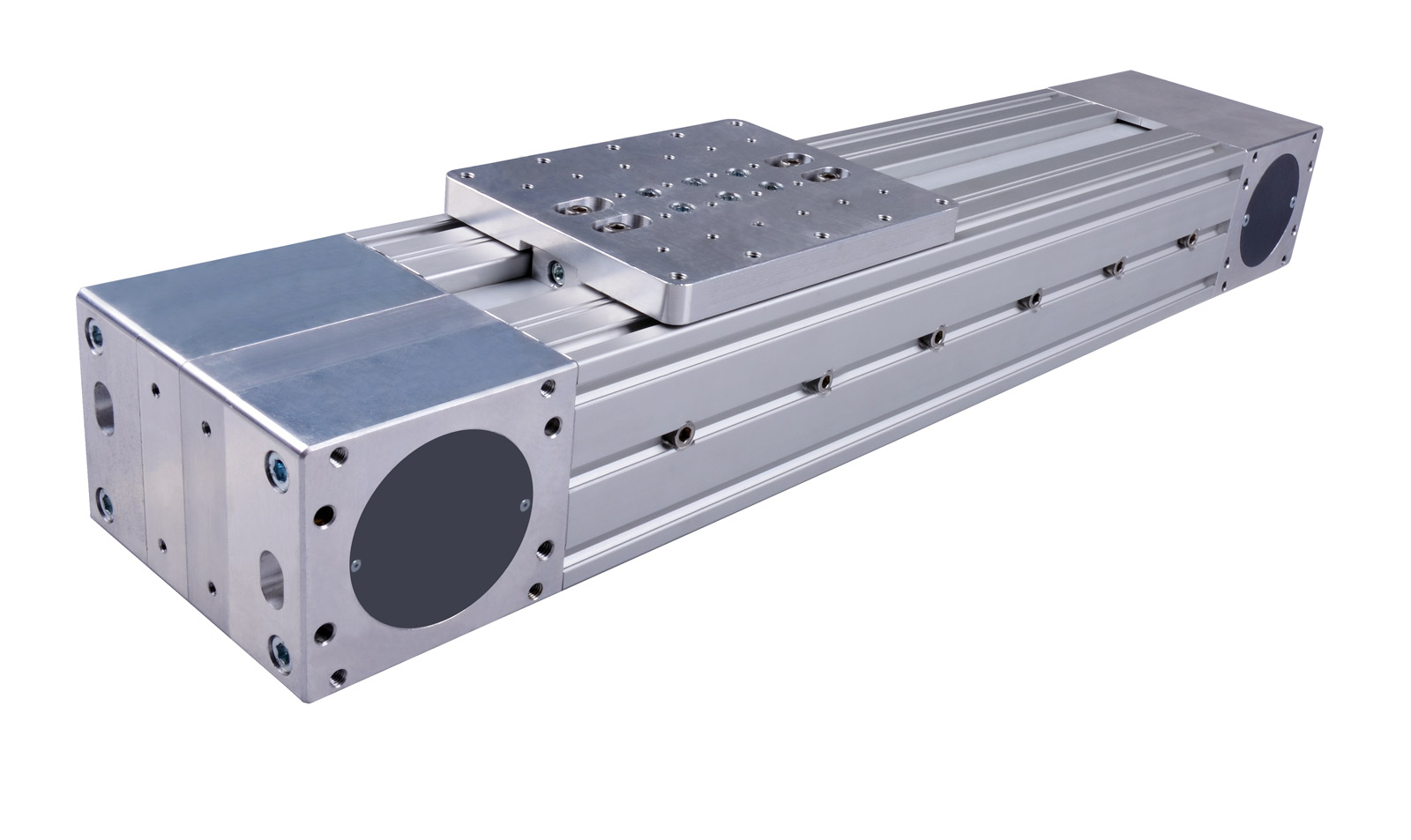

The aforementioned MLA2P is a stiffened module in which the drive is transmitted via a toothed belt. It provides a maximum axial force of up to 500 N and a linear speed of up to 2 m / s. The module has a maximum range of motion up to 2,800 mm and is characterized by a compact design as well as increased resistance to contamination.

For applications with limited installation space

For customers looking for a lightweight system for linear displacements, the MLAslim is intended, which is perfect for measuring, scanning, photography, and filming applications. The maximum linear speed is 1 m / s, the positioning accuracy is 0.1 mm, the maximum axial force is 50 N and the gear ratio is 1 rpm / 90 mm. In contrast to the standard MLA module, the MLAslim module is characterized by a compact, low-profile design. It has an integrated drive and built-in encoder, it is also possible to place the electronics in the housing.

Linear modules, depending on the customer's requirements, can be driven by a stepper motor with external or integrated electronics, a DC motor, and a servo drive. Choosing the right module for the application is made easier by the configurator available at ml.wobit.com.pl.

Multi-axis systems

For the linear modules offered by WObit, several accessories are available that allow them to be combined in various configurations and the construction of multi-axis systems (XYZ). WObit offers three standard models of Cartesian robots, made based on ML modules, they are economic, precise, and highly dynamic robots. The four-axis controller MIC488 is used to control and steer the robots. This programmable controller allows you to control up to four stepper drives or servo drives in Step / Direction mode. It is equipped with 4 encoder inputs, 8 universal digital inputs/outputs, 2 universal analog inputs 0..10 V, as well as communication ports (RS232, RS485) working in the MODBUS protocol (slave). Programming the movement is simple thanks to the intuitive software that allows you to configure the movement of drives and create programs that control individual axes, outputs, as well as react to the states of inputs or values of communication variables.

Applications

A varied offer of components and the configurability of modules allow WObit constructors to create non-standard solutions tailored to the needs of a given application. With their help, you can prepare both measuring systems and multi-axis actuators that meet various functions, from assembly and testing of elements, through pick & place operations, to sorting and palletization and depalletization of details. Solutions are selected individually after determining the required parameters and selecting the appropriate configuration of products.

MLA linear modules are the perfect basis for building test stands. One example is the charging connector testing stand, which is used to verify the mechanical wear of parts. The base of the stand is a linear MLA module driven by a stepper motor with an encoder. The system is controlled by the programmable SIC184 controller. The applied drive with control ensures precise and repeatable activation and deactivation of the tested connector. In the described application, the number of cycles during a given station start-up is counted, as well as the total number of cycles. To count and visualize the collected data, an HMI operator panel was used. The whole was easily mounted using standard connecting elements, allowing for quick and easy installation of a proximity sensor or connection of modules together to form an XY system.

Another example is the laser profilograph used to measure and acquire the profile of the road surface. The measuring system enables the verification of the road condition by determining the depth of ruts, cracks, or fraying. A profile is a record of the height indicated at a given moment by the laser sensor as a function of the path read from the incremental encoder. The measurement is carried out in the range from 45 to 90 mm, and the sensor shift is performed using the MLA linear module with a length of 1700 mm, which is controlled by the SIC184 stepper motor driver. Data is saved on an SD memory card or using a PC equipped with a special application. The device is equipped with a battery supply enabling work in the field and a recorder with a display for local presentation of current parameters.

In addition to linear modules, WObit offers, among otherslinear motors and a wide range of DC, BLDC and servo drives.Contact our advisers who will help you choose the right solution.

See our products

Class of precision robots

Class of precision robots MLA-SKX Linear module with stepper motor and integrated controller

MLA-SKX Linear module with stepper motor and integrated controller MLA-H passive module

MLA-H passive module MLAS-E passive module

MLAS-E passive module MLAS-DX Linear module with a constant-current motor

MLAS-DX Linear module with a constant-current motor MLAS-KX linear module with ball screw driven by a stepper motor

MLAS-KX linear module with ball screw driven by a stepper motor MLA-KX Rope module with stepper motor

MLA-KX Rope module with stepper motor MIC488

MIC488 SIC184 - servo-stepper motor controller

SIC184 - servo-stepper motor controller MLAS-SX Linear module with ball screw with AC servo motor

MLAS-SX Linear module with ball screw with AC servo motor MLA-DX Linear module with DC motor

MLA-DX Linear module with DC motor A class of robots with high dynamics

A class of robots with high dynamics MLAS16 reinforced version of the module with screw drive

MLAS16 reinforced version of the module with screw drive MLA-SIC Linear module with stepper motor with built-in controller + RS485

MLA-SIC Linear module with stepper motor with built-in controller + RS485 MLA-R Linear module with manual drive with crank

MLA-R Linear module with manual drive with crank MLA-SX Linear module with servo motor

MLA-SX Linear module with servo motor The class of economic robots

The class of economic robots