What can we measure?

Dimensions, tolerance, sorting, element recognition

Dimensions can be measured in various ways. In some circumstances, one sensor can measure full dimensions for small objects. In the case of larger details, the measurement can be carried out using sensors that move along one edge, thus measuring the dimensions of the object. An alternative is to measure the dimension with a static sensor and moving measuring objects, as is usually the case with assembly lines.

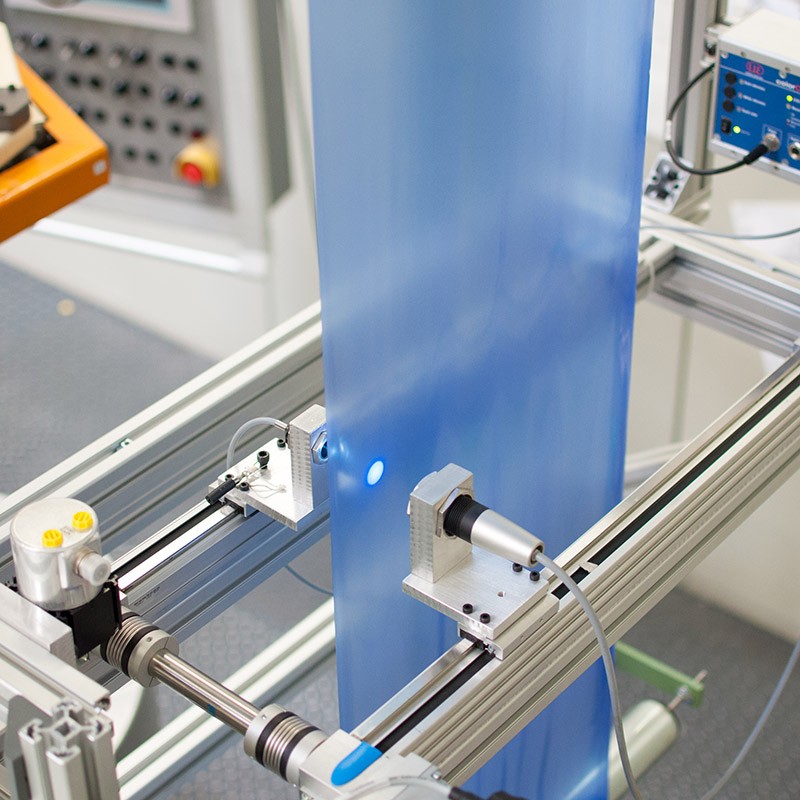

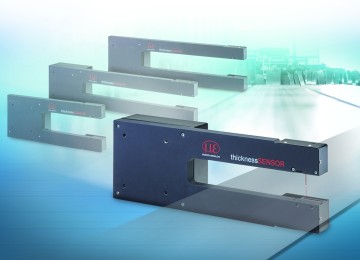

Thickness: sheets of metal, foil, rubber, insulation, layer, board

Thickness measurements are mainly used in process control and quality assurance, eg for the control of extrusion systems or 100% checking of pipe diameters. We offer measurements using non-contact displacement sensors, guaranteeing high accuracy, speed and zero emission. Depending on the needs of the application, there is a possibility of one-sided or two-sided inspection of the thickness of details.

Deviation, distortion

If objects are loaded with some kind of mass or move freely at a certain distance, there is always more or less distortion of the object. For larger objects, the measurement of this stiffness can be made using a variety of distance sensors. In the case of measuring a small element, it is necessary to use very precise measuring systems. Sensors in the WObit offer allow you to measure the accuracy of the trillion parts of the meter.

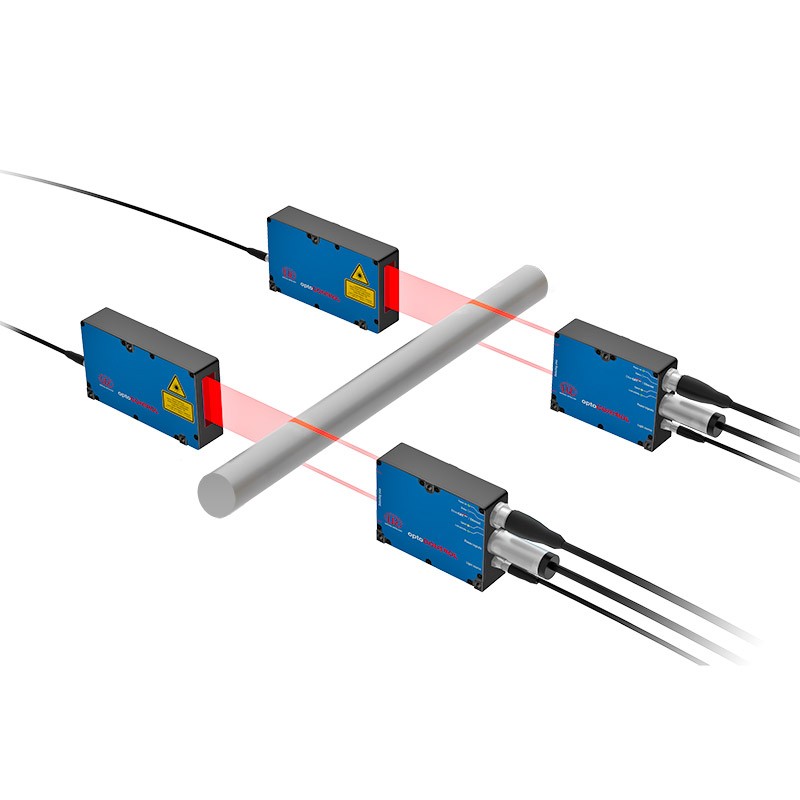

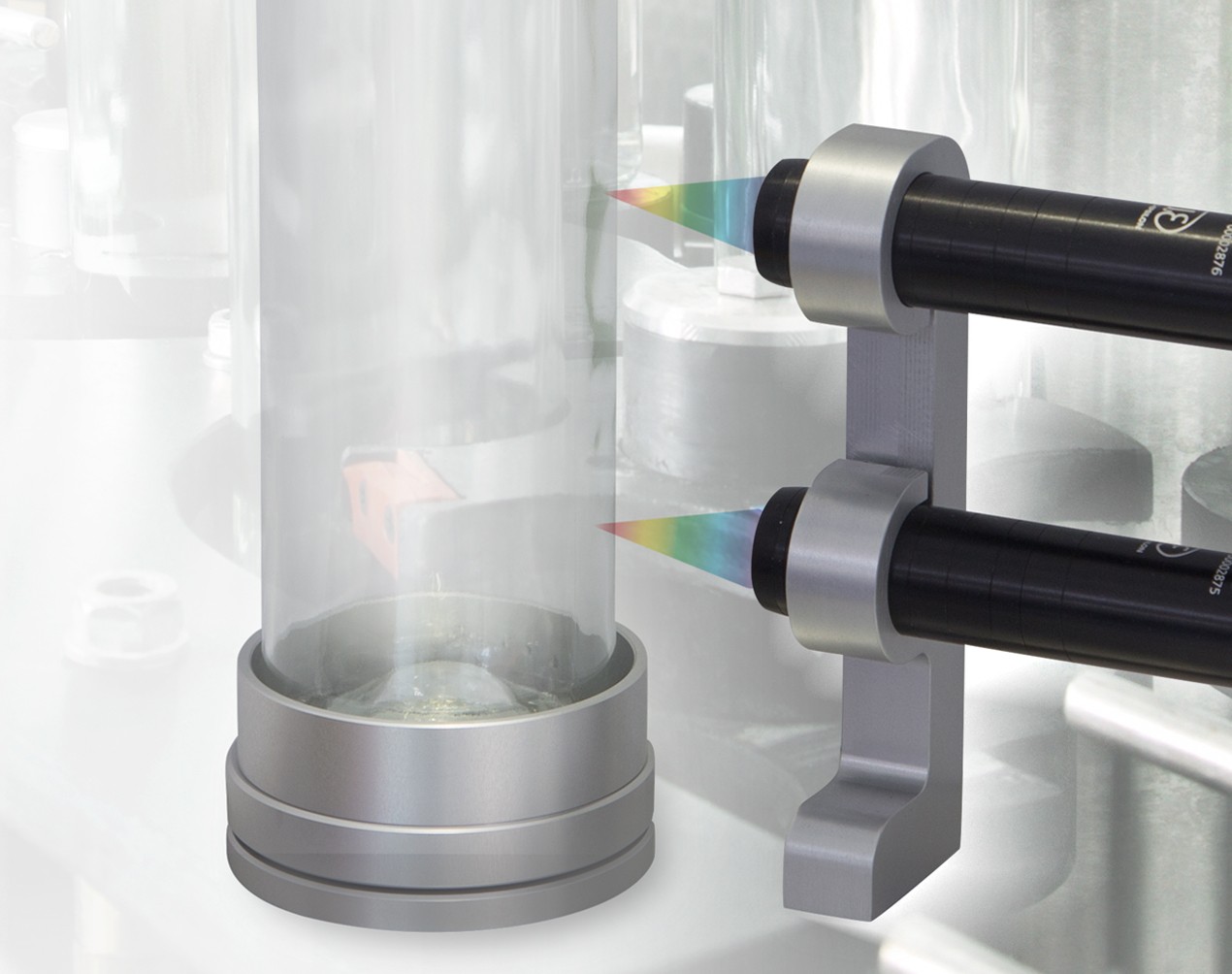

Diameters, nevertheless, rank, co-axis

The diameter of the object can be determined in various ways. If the center of the object is known, a single sensor is sufficient for measurement, the result of which is evaluated with the position of the center point or axis. If the center point is not known, the diameter is measured directly with the help of two sensors. The distance information here is also evaluated together. In special cases, if the object's opacity allows it, the determination of the diameter can also be made directly with the help of the confocal sensor.

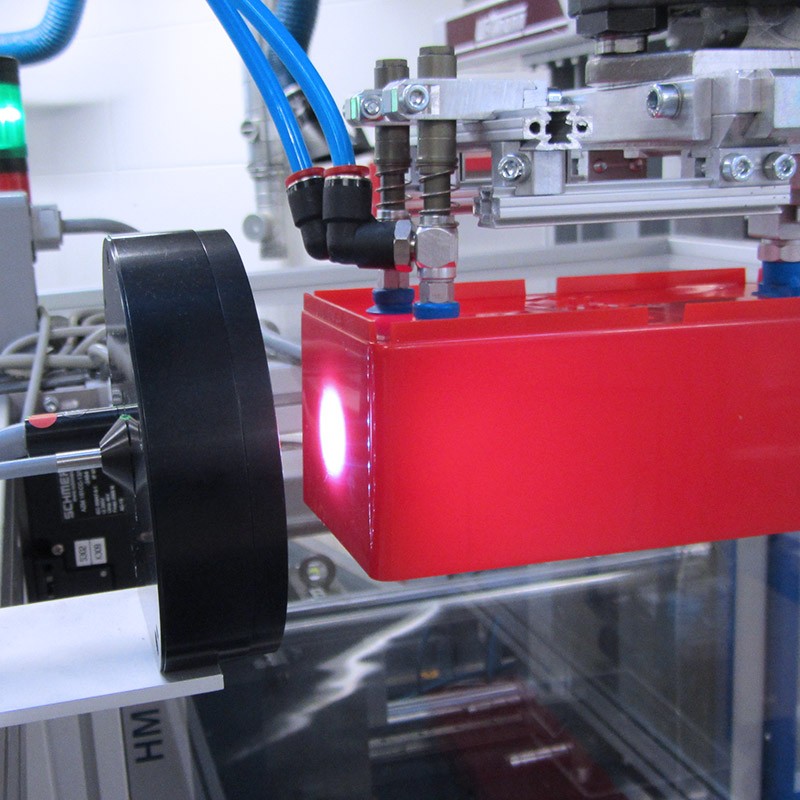

Colour

Each visible body emits a light, which is why the color can be used to evaluate objects. With the help of sensors, we can sort products by color, check incoming goods, detect colored and printed characters, control the intensity and color of the LED, and much more.

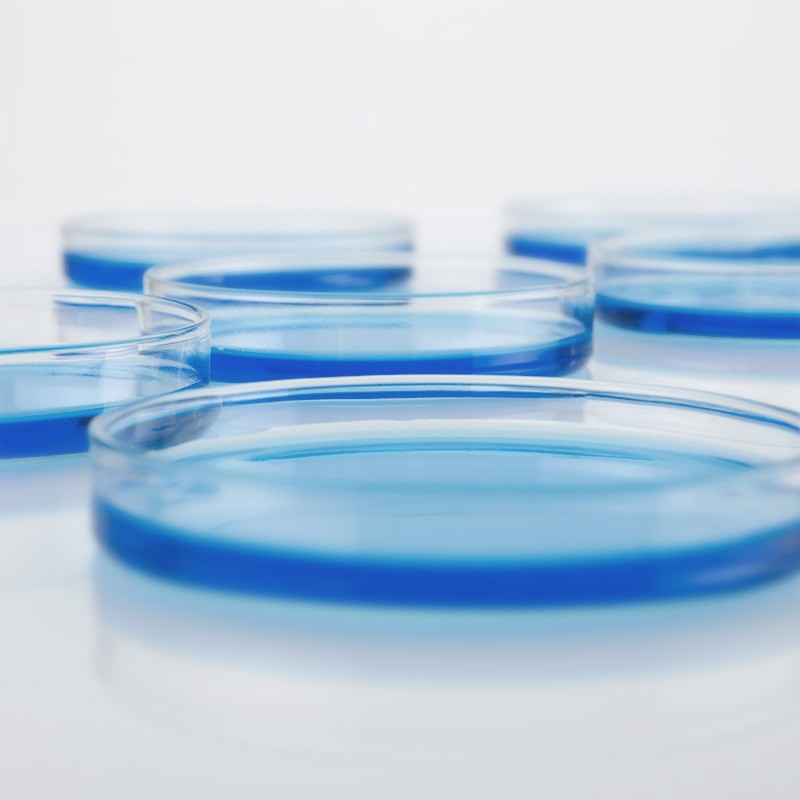

Filling level

The level of filling can be measured directly or indirectly in many ways by means of displacement sensors. The measurement of the filling level of solid bodies is comparable to the distance measurement. In the case of fluids, it is usually used with the confocal method. WObit offers a lot of different options thanks to a wide range of different sensors in its offer.

Elevation height, elevation

Lifting height is a factor that must be measured very often. The lifting height measurement is necessary wherever automated lifting processes simplify daily work.

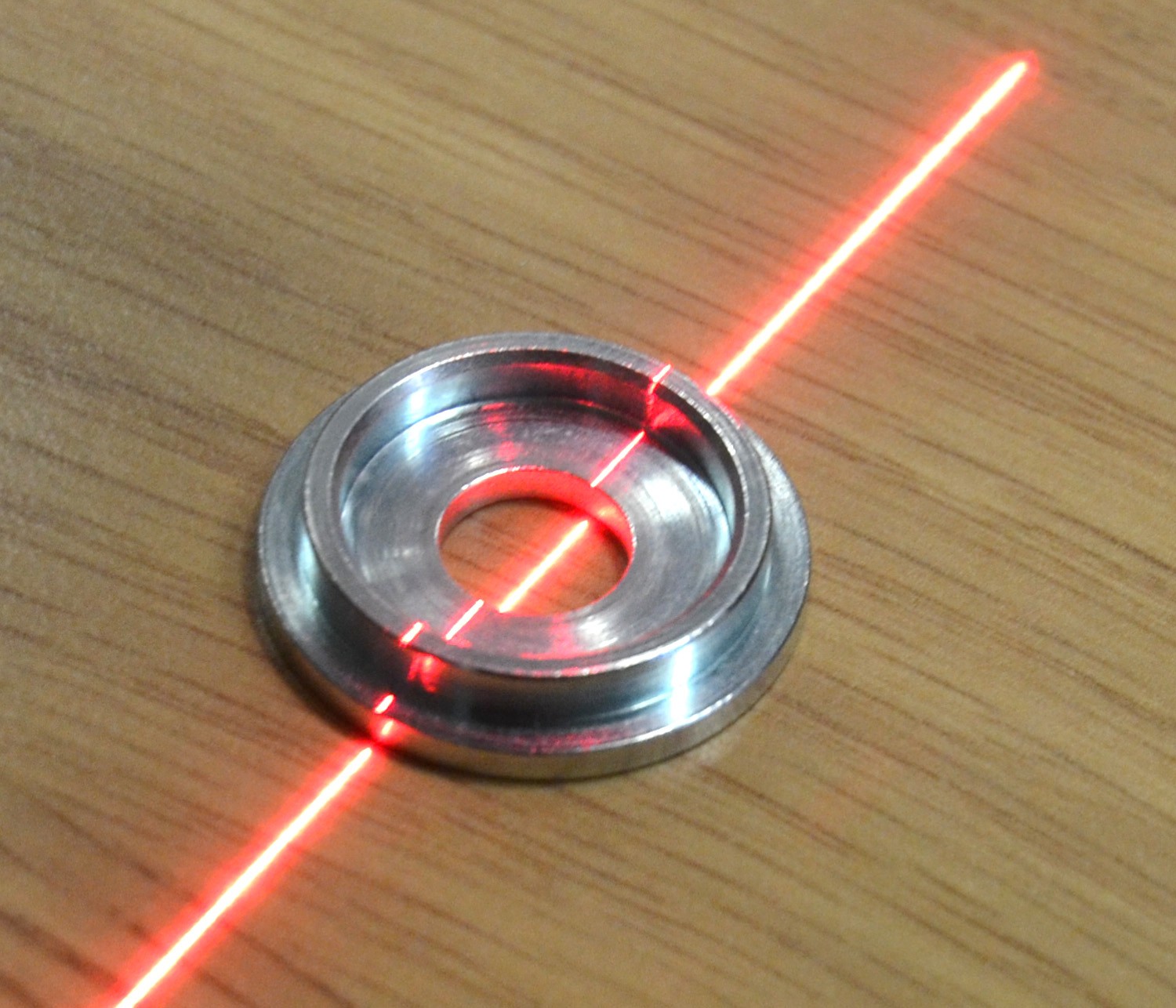

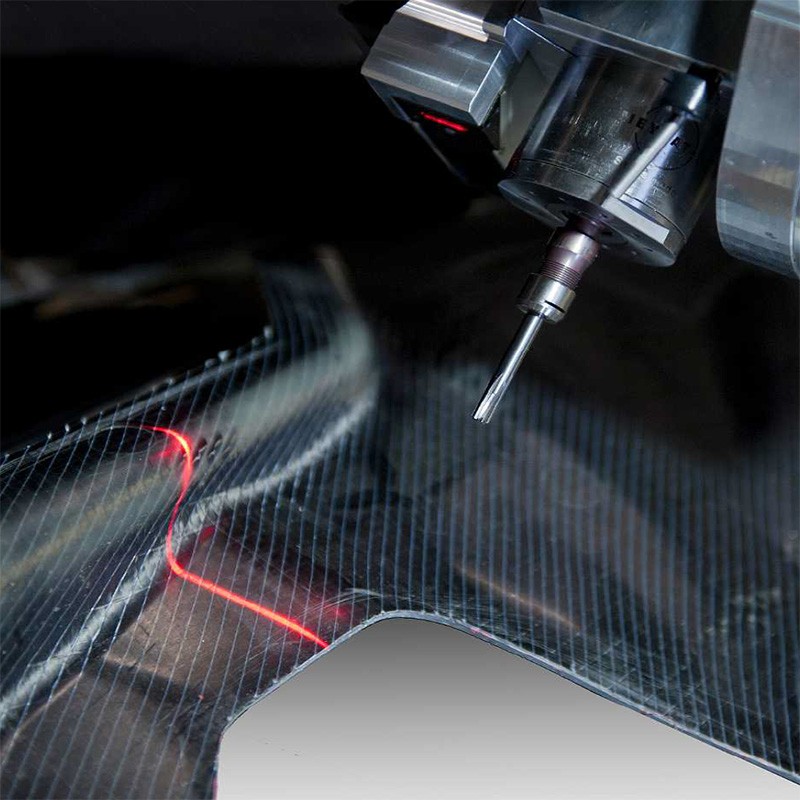

Positioning, centering, deviation, setting

Different parts or products must be often placed in a specific place in production systems or during automatic movements. In this way, the sensors can send distance information to the controller or perform full system control by means of signals.

Welding robots with automatic welding are an example of automatic adjustment. Depending on the material from which the part is made, which is to be positioned, different sensors are used.

Width

The width of the object is a very important aspect of dimension control. Width in some circumstances may have been interpreted as thickness, which is why it can be solved with the help of thickness measurement.

For the measurement of width, different measuring principles apply depending on the size of the object. In the case of large objects, such as strip material or packaging, the measurement data from two sensors is usually calculated.

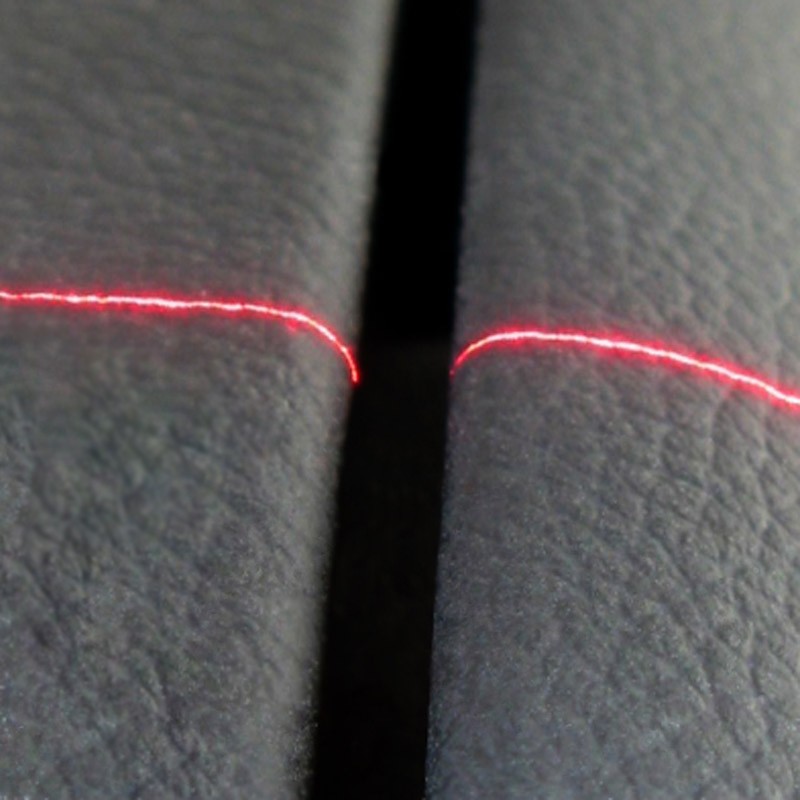

Gap

When the two edges of the object are connected together, there is always a gap between them. If the gap has to meet technical or visual requirements, please check its size in terms of size. The laser scanner series scanCONTROL is ideally suited for the overall measurement of the gap. For precise measurement of the gap on the track, also point laser sensors from the optoNCDT family are used.

Temperature

Temperature is a critical factor in many processes and often needs to be measured. Non-contact infrared measurement is often a better alternative compared to tactile methods. Stationary IR sensors are suitable if the temperature has to be continuously measured in one place, and mobile devices are used for mobile use.

Distances

Distance measurement, often referred to as displacement, describes the measurement of the distance between two points. The distance is determined in the measuring technique by the distance of the sensor from the target. In this way, distance measurement can also be determined as a measurement of displacement, distance or position. Measurements displaced in geometric measuring technology can be found in almost all application areas. We always take into account different criteria by selecting the appropriate sensor for the application.

See our products

Edge sensor

Edge sensor optoNCDT 1710/2310

optoNCDT 1710/2310 EddyNCDT 3060 eddy system

EddyNCDT 3060 eddy system optoNCDT 2300BL

optoNCDT 2300BL EDDDTT 3071 Wiring System

EDDDTT 3071 Wiring System OptoNCDT 1750-2DR laser sensor

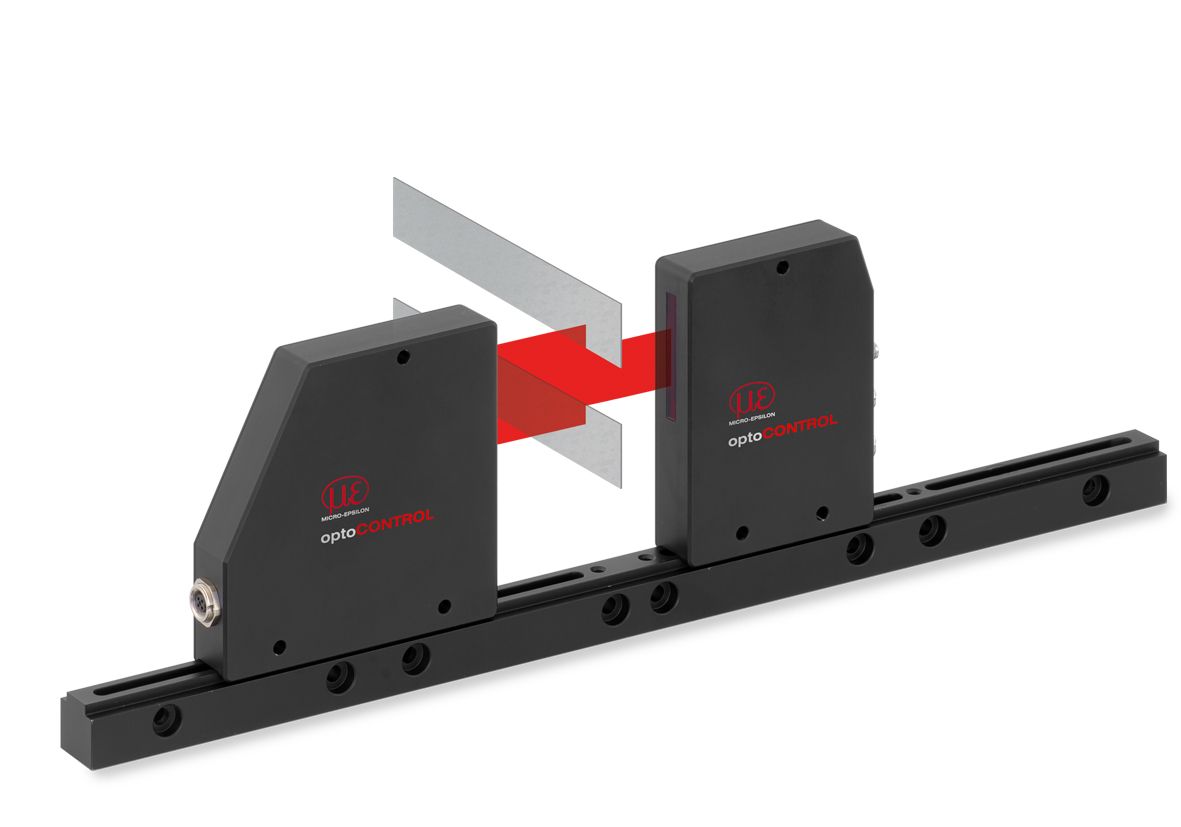

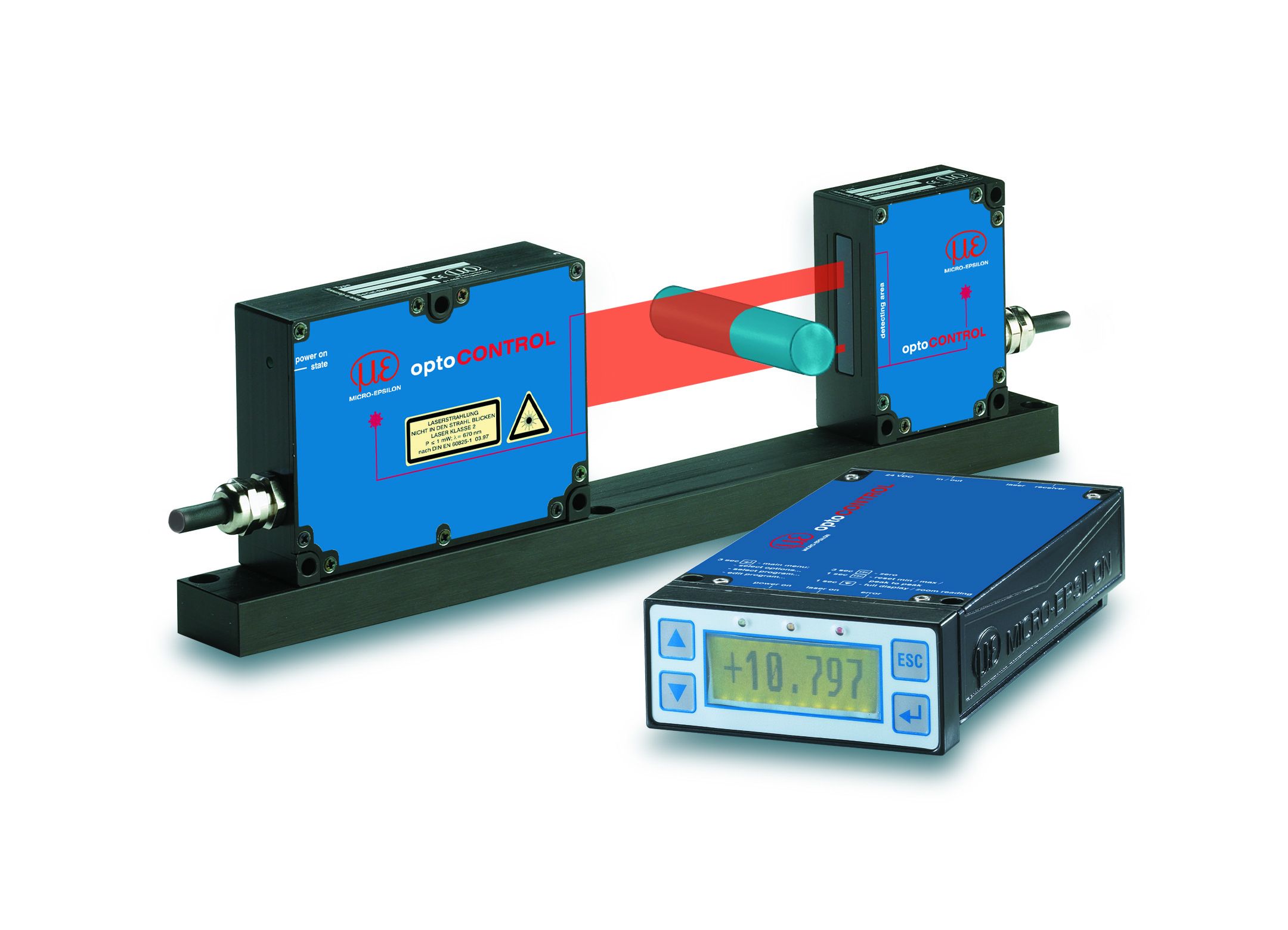

OptoNCDT 1750-2DR laser sensor  Optical micrometer optoCONTROL 2600

Optical micrometer optoCONTROL 2600 Confocal sensors

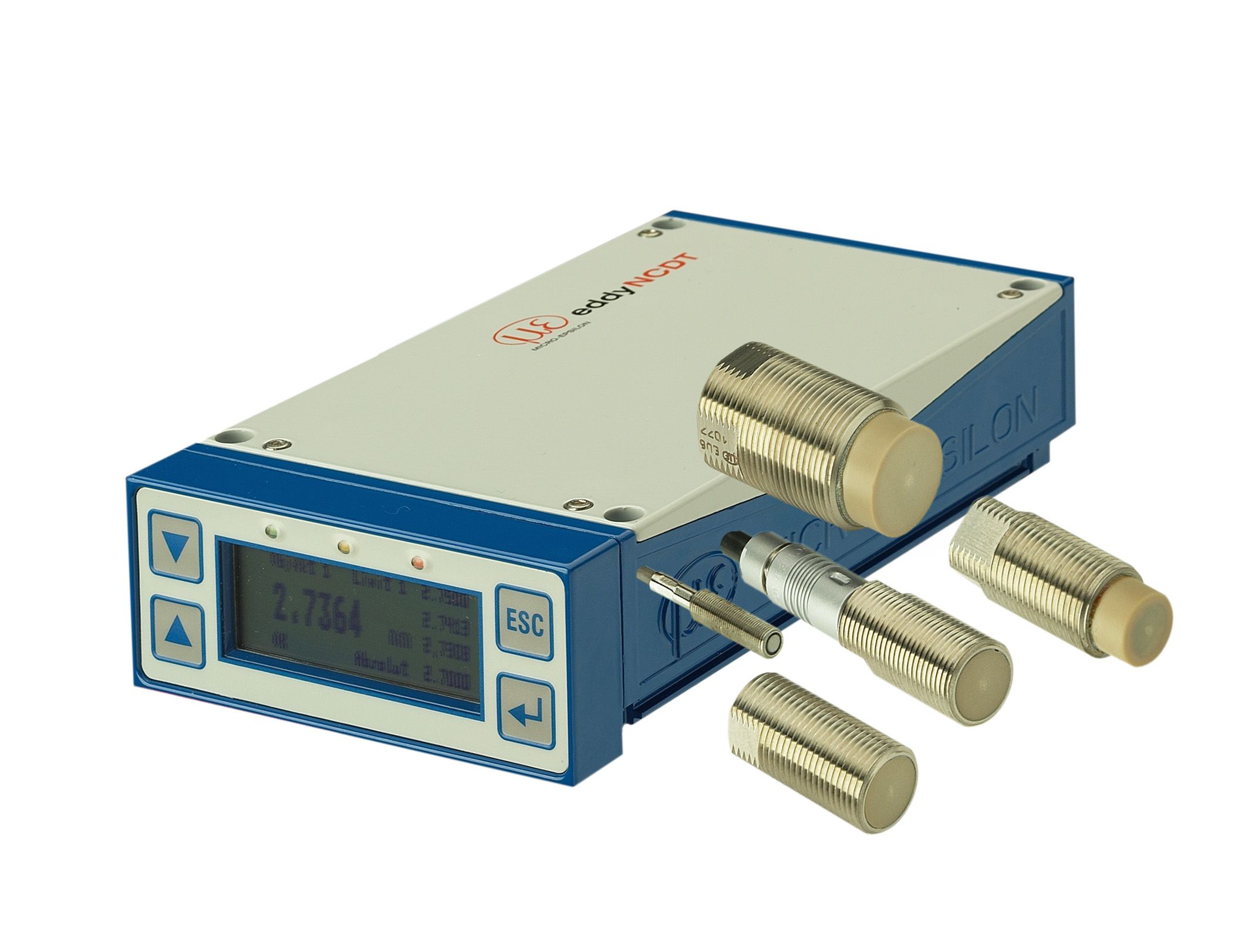

Confocal sensors EddyNCDT 3005 eddy current sensor

EddyNCDT 3005 eddy current sensor optoCONTROL CLS-K-6

optoCONTROL CLS-K-6 EddyNCDT 3010 eddy current sensor

EddyNCDT 3010 eddy current sensor OptoCONTROL 2700 optical micrometer

OptoCONTROL 2700 optical micrometer optoNCDT 1402

optoNCDT 1402 optoNCDT 1630

optoNCDT 1630 optoNCDT 1710-1000

optoNCDT 1710-1000 EddyNCDT 3001 eddy current sensor

EddyNCDT 3001 eddy current sensor OptoNCDT 1900 LL triangulation laser sensor

OptoNCDT 1900 LL triangulation laser sensor  optoCONTROL CLS1000 laser micrometer

optoCONTROL CLS1000 laser micrometer optoNCDT 1610

optoNCDT 1610 The optoCONTROL 1202 laser micrometer

The optoCONTROL 1202 laser micrometer Configuration tools

Configuration tools optoNCDT 1320

optoNCDT 1320 optoNCDT 1750

optoNCDT 1750 optoCONTROL 2520

optoCONTROL 2520 EDDDTT 3061 Viro -current system

EDDDTT 3061 Viro -current system optoNCDT 1302

optoNCDT 1302 optoNCDT 1700

optoNCDT 1700 EddyNCDT 3300 eddy current sensor

EddyNCDT 3300 eddy current sensor optoNCDT 1402SC

optoNCDT 1402SC optoNCDT 1700BL

optoNCDT 1700BL scanCONTROL BL

scanCONTROL BL optoNCDT 2300LL

optoNCDT 2300LL The optoCONTROL 1220 laser micrometer

The optoCONTROL 1220 laser micrometer EddyNCDT 3100 eddy current sensor

EddyNCDT 3100 eddy current sensor OptoNCDT 1900 triangulation laser sensor

OptoNCDT 1900 triangulation laser sensor OptoNCDT 1220 laser sensor

OptoNCDT 1220 laser sensor Optical micrometer optoCONTROL 2500

Optical micrometer optoCONTROL 2500 thicknessSENSOR - thickness measurement sensor

thicknessSENSOR - thickness measurement sensor optoNCDT 1420

optoNCDT 1420 optoNCDT 5500 Laser triangulation displacement sensor

optoNCDT 5500 Laser triangulation displacement sensor OptoNCDT 1750LL laser sensor

OptoNCDT 1750LL laser sensor optoNCDT 2300-2DR

optoNCDT 2300-2DR SGS 4701 - System for measuring the thermal spindle expansion

SGS 4701 - System for measuring the thermal spindle expansion The optoCONTROL 1200 laser micrometer

The optoCONTROL 1200 laser micrometer optoNCDT 1700LL

optoNCDT 1700LL optoNCDT 2300 Laser triangulation displacement sensor

optoNCDT 2300 Laser triangulation displacement sensor The optoCONTROL CLS-K laser micrometer

The optoCONTROL CLS-K laser micrometer optoNCDT 1420 CL1

optoNCDT 1420 CL1 System wiroprądowy eddyNCDT 3070

System wiroprądowy eddyNCDT 3070