About the Accessibility Simulator

The most important tasks of the Simulator include the development of didactics and scientific research in the field of universal design, organization and conducting of awareness training courses for academic teachers in the subject of disability and elements of universal design, and conducting laboratory classes.

The Simulator organizes meetings, training, and workshops, cooperates with the Office of Support for People with Disabilities, and coordinates changes in education programs related to the issues of universal design.

Goal

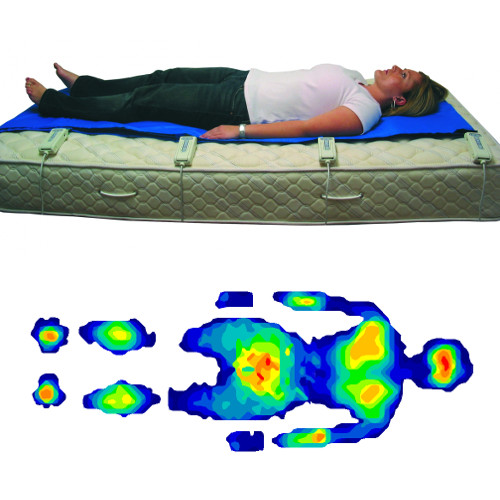

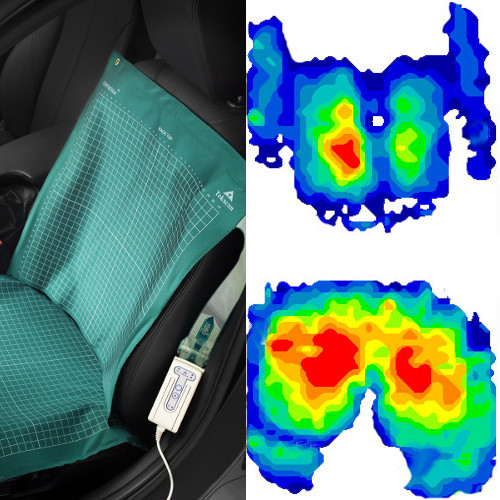

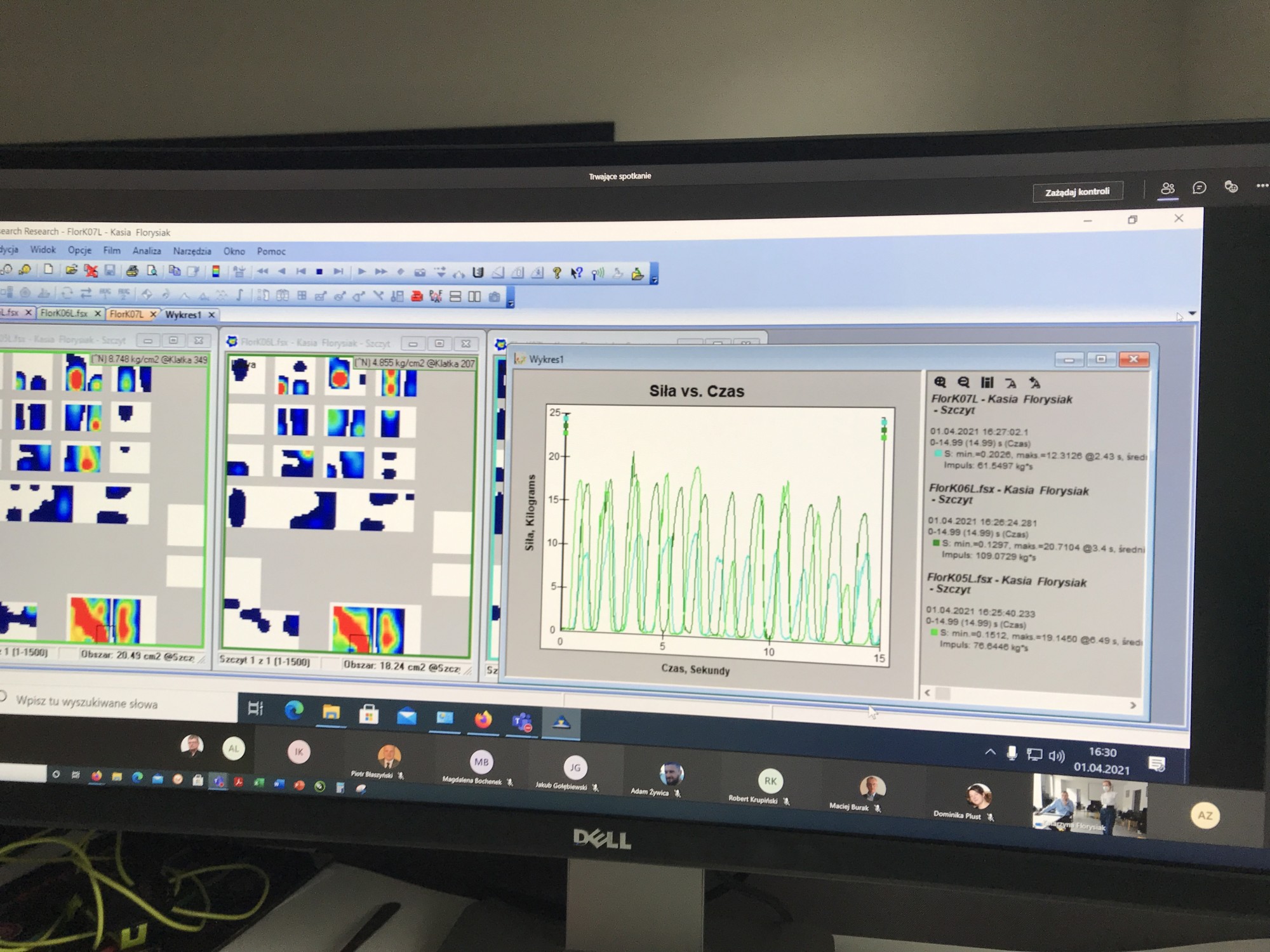

The purpose of equipping the Accessibility Simulator with systems for measuring the distribution of forces and pressure was to expand the research and measurement possibilities, especially in the field of research on the ergonomics of gripping and sitting.

The solution

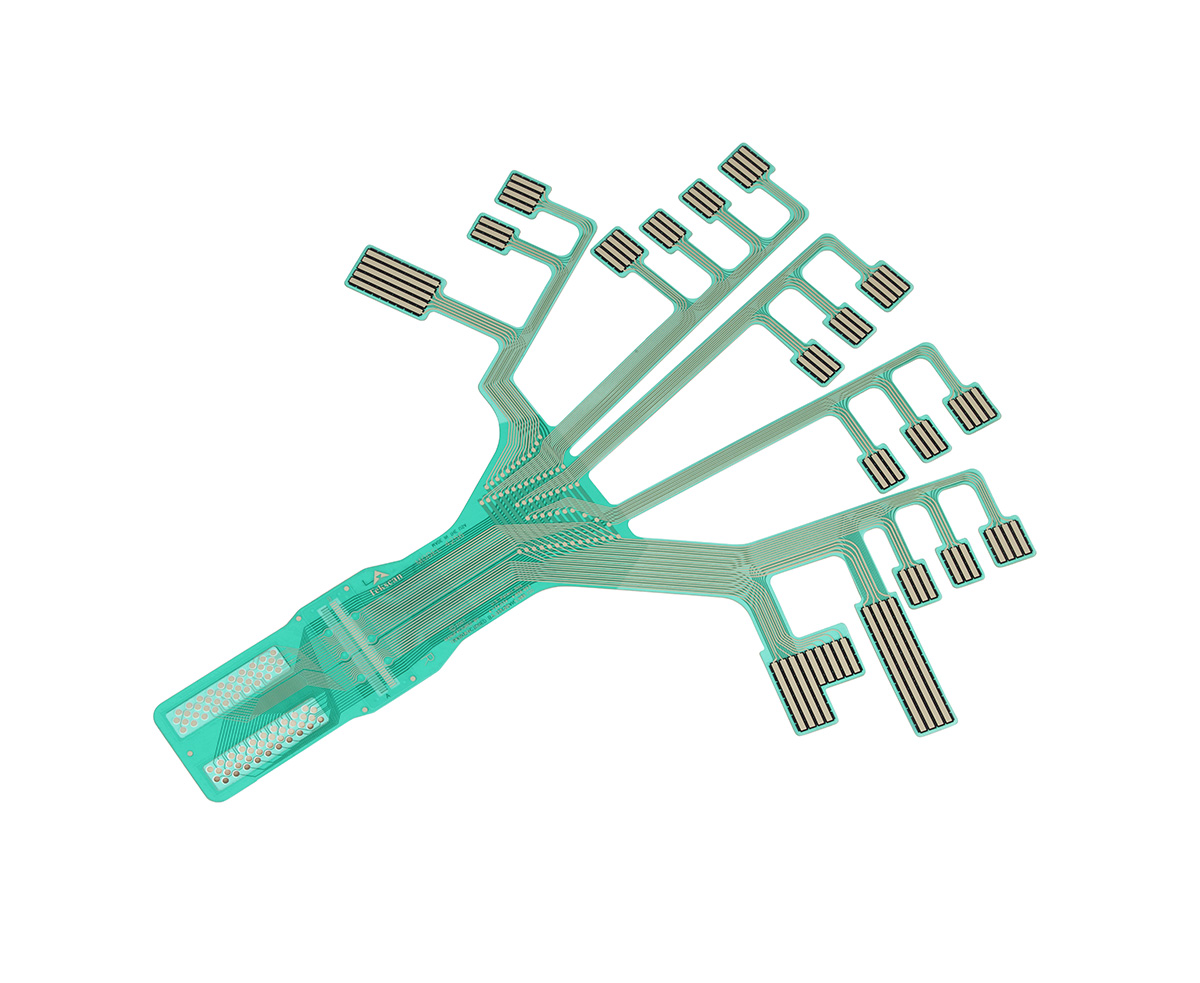

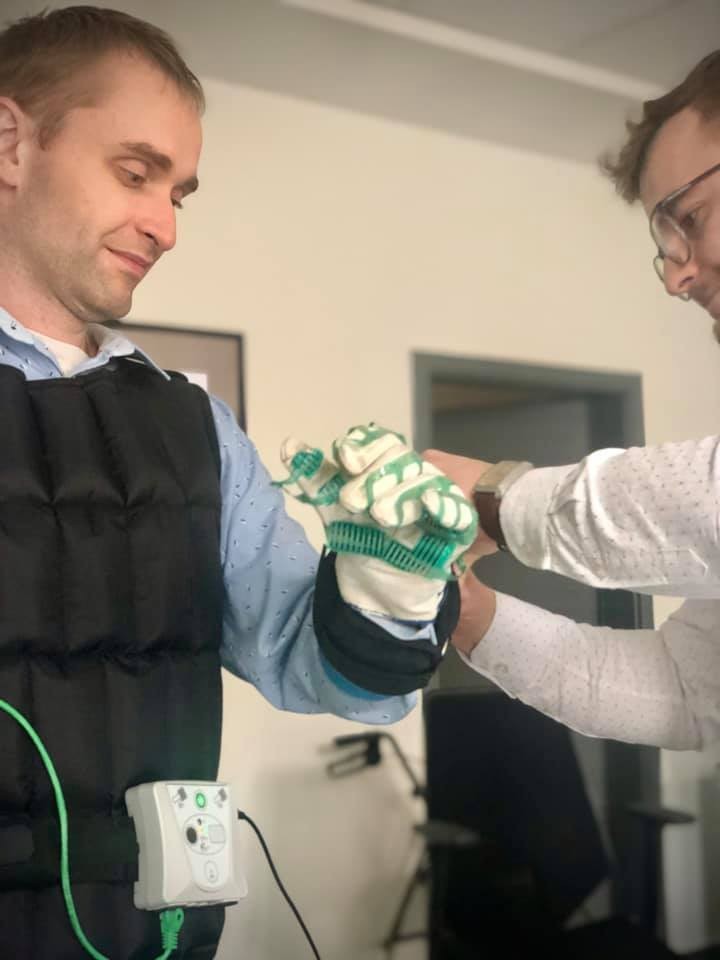

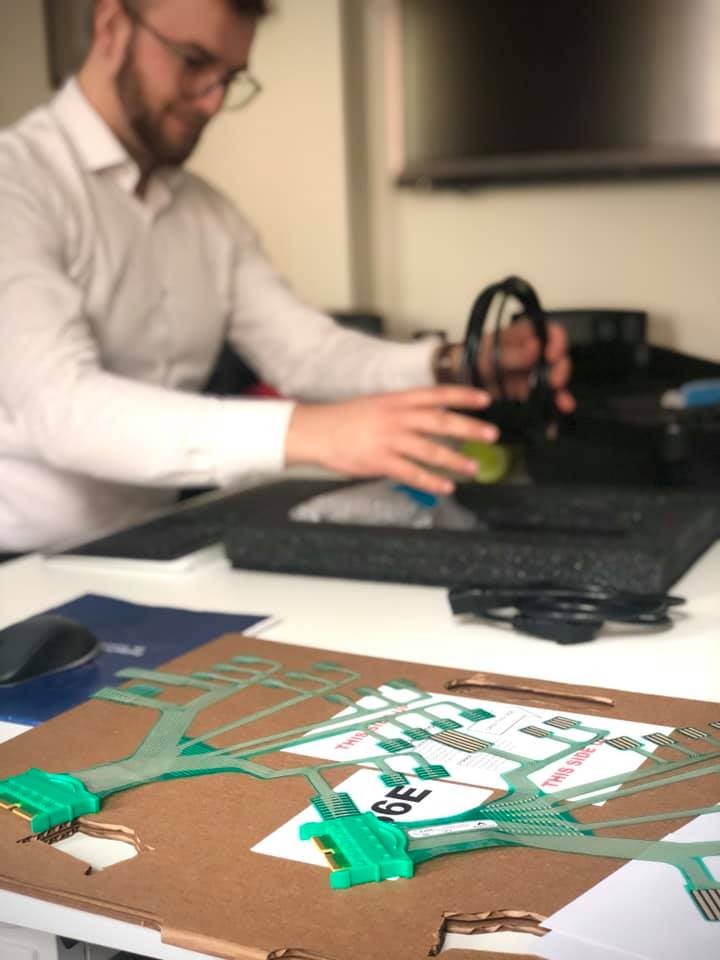

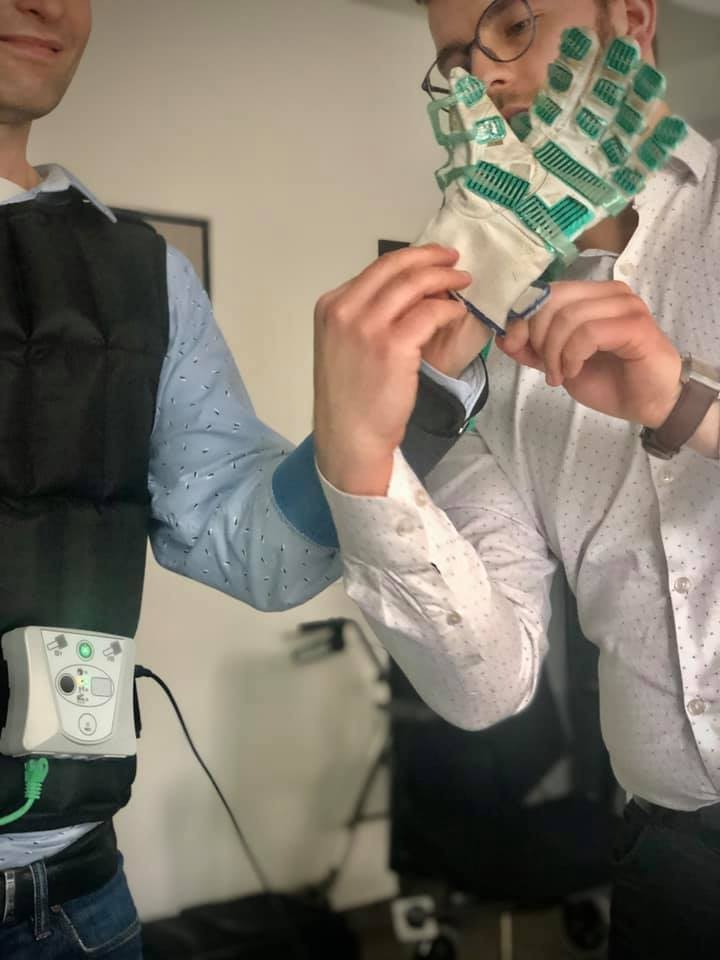

Whether the Grip system is used to improve the ergonomics of the grip or to analyze the human grip, it is the perfect tool for measuring pressure and force.

| .jpg) |

The ultra-thin mat enables its use without affecting the measured surface or changing its characteristics. The combination of these factors makes it possible to precisely measure a given location and to determine the difference between the greatest pressure and the remainder of the distribution.

|  |

Implementation and effects

After delivering the system, WObit experts conducted a three-day training for employees of the Academy of Accessible Space Development. They provided specialist knowledge related to the use of the system for measuring the distribution of forces and pressure and presented the wide application possibilities of both systems.

We hope that soon students of the West Pomeranian University of Technology in Szczecin will be able to personally test the operation of the devices.

The entry will be updated with the results of the research carried out by the Accessibility Simulator.

Source of picture: WObit oraz www.facebook.com/permalink.php?story_fbid=819675781996724&id=642558223041815

The above description can not be used in fragments or whole without the knowledge and consent of P.P.H. WObit E.K.J. Ober s.c.

Feel free to contact our marketing department:

tel. 61 22 27 410 e-mail: wobit@wobit.com.pl