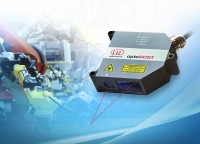

OptoNCDT 1900 is the latest model of laser sensors from the German manufacturer Micro-Epsilon. The innovative sensor offers a unique combination of speed, size and accuracy and is used for dynamic displacement, distance and position measurements. The triangulation sensor has an integrated, high-performance controller for fast and precise processing and output of measured values.

TheoptoNCDT 1900 laser sensor combines small size, precision and low weight. This makes it suitable for displacement, distance and position measurements in industry, automation and robotics. The innovative laser triangulation sensor is used wherever high precision is combined with the latest technology. Solves measuring tasks in demanding automation, automotive industry, 3D printing and coordinate measuring machines.

The measurements taken are just as reliable regardless of the surface, ranging from shiny metal to multi-colored, from light to dark, and from matt to shiny. Thanks to the small measuring spot, even the smallest parts are precisely detected, and the compact and robust design allows mounting on the robot.

The sensors are equipped with intelligent surface control. Advanced surface compensation works with new algorithms and ensures stable measurement results even on demanding surfaces. The sensor is extremely resistant to the influence of ambient light and can also be used in brightly lit places. For the first time, two-step averaging is available to optimize the signal. High-performance averaging enables precise signal paths, especially for high-speed measurements of moving parts.

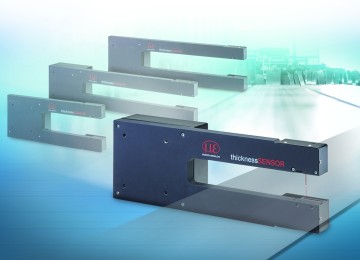

New fastening system for precise fit

Mounting by means of a mounting sleeve automatically brings the sensor into the correct position. This allows both the simple exchange of the sensor and even greater precision when solving measuring tasks. The space required for the sensor is only 70x31x45 mm. The advantages of the mounting system are particularly evident in the precise thickness measurement with two sensors of the optoNCDT 1900 series, as the light points can be precisely positioned.

See our products

optoNCDT 1320

optoNCDT 1320 optoNCDT 1700

optoNCDT 1700 optoNCDT 5500 Laser triangulation displacement sensor

optoNCDT 5500 Laser triangulation displacement sensor optoNCDT 1750

optoNCDT 1750 OptoNCDT 1750LL laser sensor

OptoNCDT 1750LL laser sensor optoNCDT 1420 CL1

optoNCDT 1420 CL1 optoNCDT 1700LL

optoNCDT 1700LL optoNCDT 2300BL

optoNCDT 2300BL optoNCDT 1710/2310

optoNCDT 1710/2310 OptoNCDT 1900 triangulation laser sensor

OptoNCDT 1900 triangulation laser sensor optoNCDT 2300-2DR

optoNCDT 2300-2DR optoNCDT 1302

optoNCDT 1302 OptoNCDT 1220 laser sensor

OptoNCDT 1220 laser sensor optoNCDT 2300 Laser triangulation displacement sensor

optoNCDT 2300 Laser triangulation displacement sensor optoNCDT 1402SC

optoNCDT 1402SC OptoNCDT 1750-2DR laser sensor

OptoNCDT 1750-2DR laser sensor  optoNCDT 1420

optoNCDT 1420 thicknessSENSOR - thickness measurement sensor

thicknessSENSOR - thickness measurement sensor optoNCDT 2300LL

optoNCDT 2300LL OptoNCDT 1900 LL triangulation laser sensor

OptoNCDT 1900 LL triangulation laser sensor  optoNCDT 1700BL

optoNCDT 1700BL optoNCDT 1630

optoNCDT 1630 optoNCDT 1402

optoNCDT 1402 optoNCDT 1610

optoNCDT 1610