Thickness measurements using triangulation sensors have a wide application area. They can be divided into contact and contactless, single and double-sided, destructive and non-destructive. WObit company proposes the use of Micro-Epsilon sensors, which allow for the implementation of various measuring tasks.

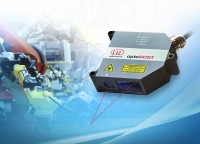

In the production process, it is often necessary to measure the thickness of the material, e.g. paper or metal subjected to the rolling process. To perform such a task, laser sensors from the optoNCDT series can be used . They measure based on the principle of optical triangulation. The laser diode illuminates the point on the surface to be measured (2nd class laser). The light reflected from this point is directed to the light-matrix matrix where it is processed in real time.

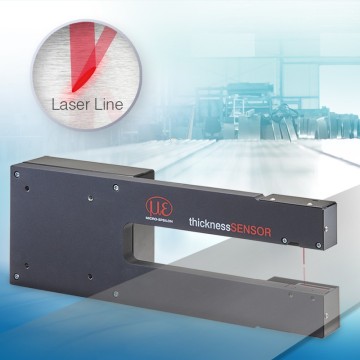

A good way to check the thickness of the material is to make a differential measurement. The principle of differential measurement consists in combining two synchronously acting sensors with each other and subtracting the values â??â??measured by them from the distance between them. Thanks to this solution, when the measured object moves within the measurement field, the measured value does not change, because constant compensation occurs. When, due to the movement of the object, the value measured from one of the sensors grows, the value measured from the other sensor decreases proportionally so that the circular result remains unchanged.

For the differential measurement, WObit proposes the use of optoNCDT2300 sensors placed above and below the material and moved in the xy system based on WObit linear modules. The series of sensors has an adjustable measurement frequency of up to 49.02 kHz. A great advantage is the integrated electronics and compact dimensions of the sensor. optoNCDT2300 is equipped with real-time surface compensation (RTSC system), remote programming, excellent linearity of up to 0.4 Ă?Îźm and resolution up to 0.03 Äžm. |  |

Dedicated software allows you to easily set measurement thresholds and their compensation. The device is equipped with Ethernet, EtherCAT and RS422. Thanks to their functions, these sensors are suitable for quick and precise measurements, also for surfaces that directly reflect the light. A special protective casing is available for use in harsh environmental conditions.

| In order to collect and display measurement data from two optoNCDT2300 triangulation sensors � you can use MD152A indicator with two 0â" 10V / 4â "20mA inputs, dedicated for differential measurements. Indicator MD152A is equipped with two relay outputs, which can be signaled by user-defined measuring thresholds. |

The device also has a USB connector for quick configuration and for recording measurement data to a file, as well as an RS485 interface (Modbus-RTU). More information about sensors, measuring devices and their applications can be found at www.wobit.com.pl .