Rotary-pulse transducers are one of the most frequently used measuring elements in automation. They are implemented everywhere where it is necessary to precisely determine the angular position, number of revolutions, distance traveled and rotational speed. The company WObit aware of these needs offers excellent incremental and absolute encoders along with measuring devices in-house production.

Depending on the type of signal generated at the output and the possibility of storing the measured quantity, rotary-pulse transducers can be divided into incremental and absolute. An incremental encoder on the output generates a pulse signal, and the number of pulses per revolution determines its resolution. This type of transducer does not remember the current position, it only produces impulses for counting which an external device (controller, meter) is needed for. Unlike incremental converters, absolute encoders enable the current position even after voltage decay.

| Absolute optical pickups generate a code signal on the output (binary code or Gray). The code is placed on a coding disk, which is a movable element mounted on the shaft of the encoder. When the shaft is rotating, the unique combination of photoreceptors is illuminated or the supply of light is blocked by the pattern on the dial. |  |

Absolute optical encoders can still be divided into single-turn and multi-turn, which in addition to the position also remember the number of turns. Thanks to such advantages as quick response and easy to use output interfaces, these devices are used in many traffic control applications.

In their basic design, optical pickups are not suitable for use in dirty, dusty and potentially humid environments. For difficult ambient conditions, they must be made in a special housing or with additional sealing. With a more complex design, however, you have to count on the increase in the cost of the device.

For magnetic rotary encoders there are a variety of output signals such as analog (voltage and current), PWM, incremental, absolute, SSI and SPI. In the case of shielded cables, these encoders are insensitive to the influence of a strong magnetic field. In terms of accuracy and resolution, magnetic pickups ustzÄ?ujÄ?Ä? for example, optical encoders, however, have simpler, compact construction and lower adaptation requirements, it is also a slimmer solution with regard to optical technology.

To cooperate with rotary-pulse transducers, WObit specialists have prepared various types of measuring devices that allow simple signal processing from one or more devices. In applications where you need to count pulses from incremental encoders or rectangular signals and displaying the results locally, it will be perfect to check programmable MD150E counter .

| This device can also specify the frequency of the signal and Ă? rescale the calculated value on the required unit (rotations, mm, rev / sec, etc.). The meter is equipped with a USB connector that allows it to be directly connected to the computer, and the MD150E-PC, supplied with the device, allows quick configuration of the indicator and measurement recording.MD105EĂ? also has a Modbus-RTU interface for communication with industrial devices (PLC, HMI) and two relay outputs that can be signaled by the measuring thresholds set by the user. |  |

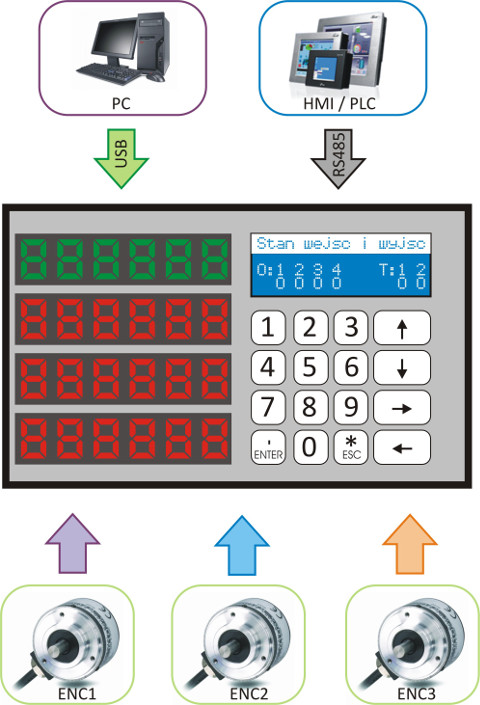

For applications in which simultaneous display of results with three devices is required, and also adding them together, WObit has prepared MD400E module . The device is equipped with four LED displays for road or speed presentation and one visual display, which together with the numeric keypad provides the operator interface.

| The MD400 counter also has four OC type transistor outputs (open collector) with a configurable threshold, depending on position or the speed of one of the encoders.Moduł MD400Ă? has been equipped with two popular communication interfaces â USB and RS485 Modbus-RTU An interesting application for the use of such a universal device is their implementation in machine tools, in which several axes are positioned. The MD400 allows digital readings of offsets and speeds of these axes (counted by the used encoder). Another place for uselicznika MD400There are various types of production lines |

For example, you can count products on three lines and display the results separately for each production line. The fourth display can be used to present the sum of the values â??â??from the three remaining displays. Controlling the production process. Thanks to the MD400 module, you can become much simpler and more efficient, and the performance capability is comparable with much more expensive technologies.

| When it is not necessary to display the results, but there is a need to count signals with several devices, you can usemoduł pomiarowy ADE4U. It provides the perfect basis for creating multi-point measuring systems, allows you to control the position and speed of four independent working encoders.Moduł pomiarowy ADE4-UĂ? has a five-way transistor output OC type with configurable switch-on and switch-off thresholds depending on the position of the encoder. |  |

After programming the appropriate switching thresholds, ADE4-U you can work as an independent device (without PC supervision). Similar to the previously described WObit devices, ADE4-U is equipped with a USB connector and an RS485 Modbus-RTU interface

| Measurement systems with impulse rotary transducers can be used to measure the material produced on process lines. To the measuring system you can implement transducers with a measuring wheel, eg from a seriesENCĂ? LubaMWK. Thanks to the integrated arm, it can be mounted above the technological line. The transducer then rests on the measuring wheel on the material being measured and presses the gearbox with the weight of the entire encoder with the arm. |

Another application of the measurement system based on modušĹ? pomiarowy ADE4U is to measure the scrolling material from the role. Depending on the used encoder, the system can be used to measure the relative material length and control the cutting process for specific sections (eg rolls of roofing paper, paper, glass, cardboard, wood, plastic and metal profiles), and even the counting of daily production or productivity of the production machine .