The WObit company is expanding its portfolio of autonomous mobile robots with omnidirectional drive by a new model, designed for transporting loads up to 700 kg. FlatRunner MW HT has an extremely compact design only 220 mm high , 1500 mm long and 700 mm wide.

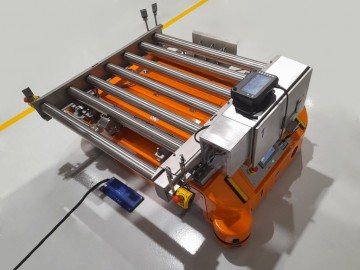

These dimensions allow, among others for driving under shelves and their automatic picking and putting in to specific places. What's more, shelves and other loads, e.g. pallets or roller conveyors, can weigh up to 700 kg. The new autonomous mobile robot is powered by efficient lithium-ion batteries that allow uninterrupted operation up to 5 hours.

MOBOT® AGV FlatRunner MW HT is equipped with a four-wheel omnidirectional drive that allows you to drive in every direction and rotate 360 ° in place. Mecanum wheels provide freedom of maneuver, flexibility and reduce the time it takes to complete tasks - MOBOT® does not have to perform any additional maneuvers like turning back. Therefore, robots with this drive are suitable for processes with a short cycle time, as well as for work in places with limited space (narrower corridors).

MOBOT® AGV FlatRunner MW HT independently moves in the environment using the LMS navigation system (laser mapping system). With its help, the robot creates a map of the environment in its memory and by scanning space while driving, sees naturally occurring objects, such as walls, so that it always knows exactly where it is. Importantly, this navigation method does not require any interference in the factory or warehouse space, and its implementation and reconfiguration are very fast. It also allows you to bypass obstacles that robots encounter on their way.

The new mobile robot, like other MOBOT® robots is equipped with an advanced security system, which includes laser scanners with security function. They are responsible for detecting obstacles appearing in front of the mobile robot. Thanks to this works safely with people , transporting various loads.

MOBOT® AGV FlatRunner MW HT is the optimal tool for handling inter-operational transport in just-in-time processes in production and in warehouses. The unusually low design can be integrated with a load lifting system, allowing for automatic picking up and setting down e.g. pallets. In addition, the robot can be easily adapted to transport a variety of loads by replacing modules / adapters, e.g. with automatic rollers, to transport packages or a robotic manipulator. This is the optimal solution for transporting loads in industry and warehouse logistics.

The implementation of the robot is quick and simple and does not require costly changes in the spaces in which they are to operate. The robot system is also scalable , which means that it can easily be expanded with additional devices.

The use of MOBOT® mobile robots to automate transport increases productivity and allows cost reduction. This is due to better control of the flow of goods, safer and careful transport, as well as saving the time of employees who can take on more interesting tasks that require higher qualifications. Mobile robots also improve the ergonomics of people's work. As a result, we obtain more efficient use of resources and space.

To learn more about the new mobile robot MOBOT® AGV FlatRunner MW HT and the entire device family, visit www.wobit.com.pl or contact WObit advisors at number 61 22 27 422.

See our products

MOBOT® AGV eRunner 003 mobile robot

MOBOT® AGV eRunner 003 mobile robot Mobot® Xarm - mobile manipulator

Mobot® Xarm - mobile manipulator Mobile robot MOBOT AGV eRunner MW

Mobile robot MOBOT AGV eRunner MW MOBOT® AGV FlatRunner MW HT mobile robot

MOBOT® AGV FlatRunner MW HT mobile robot MOBOT® AGV FlatRunner HT 004 mobile robot

MOBOT® AGV FlatRunner HT 004 mobile robot MOBOT® AGV CubeRunner MW mobile robot

MOBOT® AGV CubeRunner MW mobile robot MOBOT® TRANSPORTER mobile robot

MOBOT® TRANSPORTER mobile robot MOBOT® AGV CubeRunner2 004 mobile robot

MOBOT® AGV CubeRunner2 004 mobile robot MOBOT® TRANSPORTER T15 mobile robot

MOBOT® TRANSPORTER T15 mobile robot Mobile robot MOBOT® AGV FlatRunner MW Light

Mobile robot MOBOT® AGV FlatRunner MW Light MOBOT® TRANSPORTER T5 mobile robot

MOBOT® TRANSPORTER T5 mobile robot Industrial mobile robot MOBOT® AGV FlatRunner MW

Industrial mobile robot MOBOT® AGV FlatRunner MW