In all cases where it is necessary to make measurements and visualization of values â??â??such as temperature, strength, digital or analog signals, use indicators and measuring devices . In many processes, these devices are also used to regulate and control processes, and increasingly they form part of larger systems, thanks to linking them with SCADA systems .

Weight measurements

Frequently measured values â??â??in various fields of the industry, such as the food industry or plastics processing, are weight and weight. For the measurements, the most frequently used are tensometryczne due to their high sensitivity and accuracy, while maintaining a small size. WObit offers a variety of sensor models that, depending on the housing design, can be used to measure small forces in single-newton ranges, as well as huge forces counted in hundreds of kilonewtons.

In addition to the sensor itself in weight systems, it is essential to be easy to use, and at the same time a functional device to collect data and process measurements. Rising demands on the efficiency and quality of the processes have inspired the constructors of WObit to develop amplifier WDT11 dedicated for the cooperation with strain gauges. It has been equipped with a digital transducer allowing to precisely measure its strength and convert it into a 4-20 mA (or 0-10 V) signal and a digital RS485 signal. WDT11 has a built-in RS485 interface with the MODBUS protocol, which allows direct communication of one or several modules with a PLC or HMI panel. You can connect up to thirty two modules on one bus. Special software for a PC computer that allows configuration is intended for the configuration of WDT11 via the USB connector and viewing the current measurement values. |  |

In order to present the results in applications locally, along with the WDT11 module, display DE38 . It is equipped with a Modbus-RTU interface, enabling cooperation in both master and query mode of measurement modules as well as slaves when passing values â??â??to a PLC. A six-digit LED display with a 38-mm high digit guarantees a clear presentation of the value even from a long distance.

Modules with analogue input

The measuring device with universal application is programmable MD150E counter designed for counting pulses from incremental encoders or other sources generating digital pulses. MD150E can also specify the frequency of the counted signal and rescale the calculated value on the required unit (revolutions, mm, etc.). The device also has two relay outputs and a resetting output. MD150E is equipped with a USB connector for communication with a PC computer and in RS485 Modbus-RTU. The free application on a PC allows quick configuration of the pointer and recording of measurements to a file.

| One of the interesting applications where the indicator was applied was the measurement of the efficiency of workers who used small plastic parts. Along with the module, an optical proximity sensor was used, placed in a specially prepared spill for finished products. After the worker has thrown a folded product into the drain hole, the signal from the sensor is passed to MD150E , which counts these signals and presents the results on the display. Thanks to Modbus-RTU RS485 communication, it is possible to collect data from each meter separately, which makes it easy to keep employee performance statistics. |

Thickness measurement

In the wood or paper industry, it is often necessary to control the thickness of finished products. To perform such a task, laser sensors from the optoNCDT series can be used . They measure based on the principle of optical triangulation. The laser diode illuminates the point on the surface to be measured. The light reflected from this point is directed to the light-matrix matrix where it is processed in real time.

A good way to check the thickness of the material is to make a differential measurement. The principle of differential measurement consists in combining two synchronously acting sensors with each other and subtracting the values â??â??measured by them from the distance between them. Thanks to this solution, when the measured object moves within the measurement field, the measured value does not change, because constant compensation occurs. When, due to the movement of the object, the value measured from one of the sensors grows, the value measured from the other sensor decreases proportionally so that the circular result remains unchanged.

In one of the applications to control the thickness of the board, eight optoNCDT1420 laser sensors that perform differential measurements. Four sensors were placed from the bottom of the board, and the next four on the other. These compact sensors with a measuring range of up to 200 mm have been chosen for their unique combination of speed, size and performance. The sensors allow for obtaining a stable signal even with a measuring frequency up to 4 kHz. In the settings manager, you can store and export up to eight different, specific configurations. Loading stored settings into several sensors (as in the case of a given application) allows very fast setting of parameters. Thanks to functions such as maximum signal selection and adjustable signal averaging, it was easy to optimize the measurement. |  |

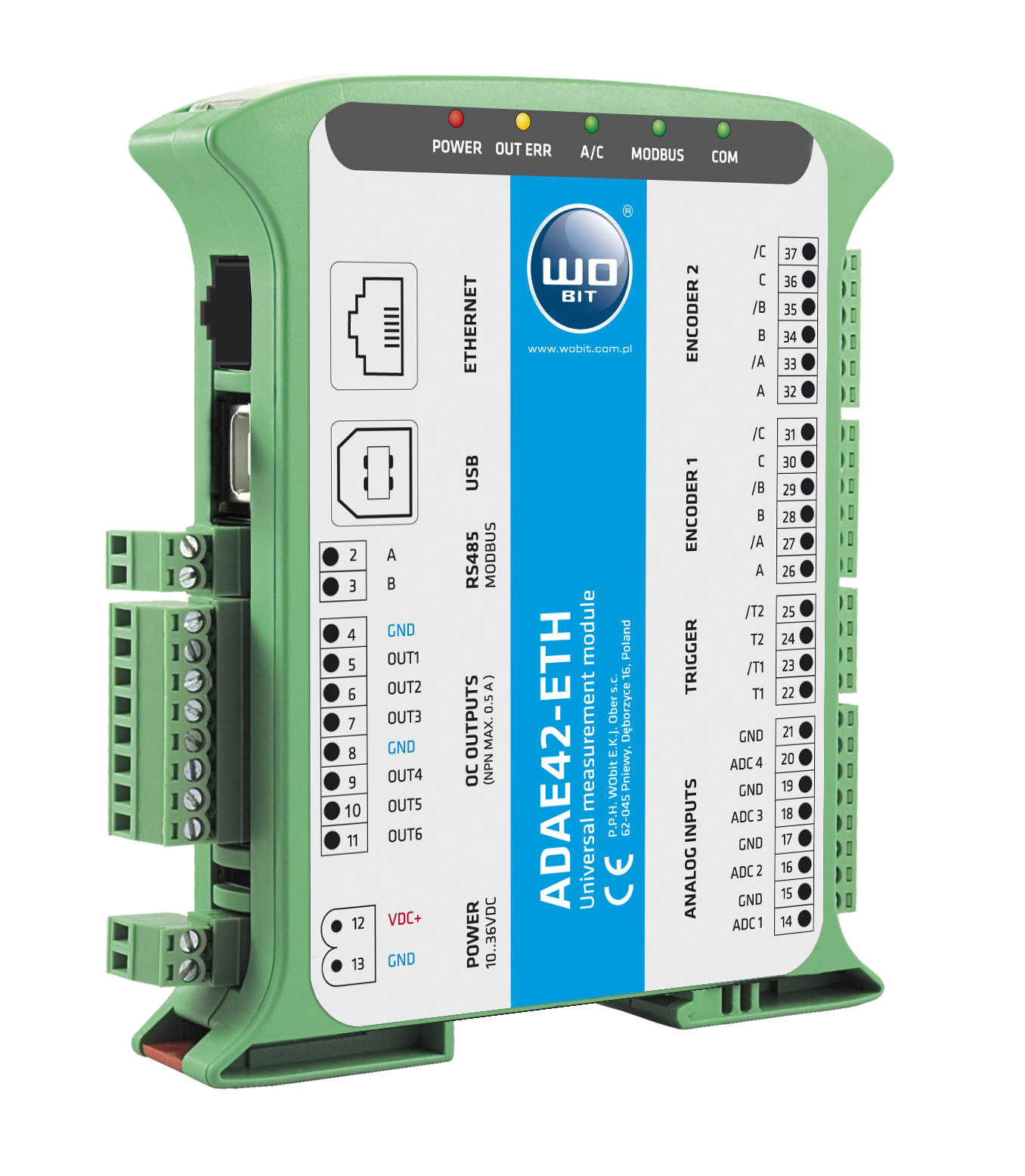

| To collect and display measurement data from eight laser sensors in control of board thickness, two multi-channel ADAE42-ETH measurement modules. The device is dedicated to cooperation with four sensors with an analogue output (voltage or current) as well as with two impulse-rotary or linear converters with a quadrature output. It is additionally equipped with six OC type transistor outputs with a configurable switch-on and switch-off threshold, depending on the value of analog inputs, mathematical registers, position or encoder speed. |

ADAE42-ETH measuring module in addition to the USB and RS485 interface also has Ethernet. This interface has been used in the application to transfer the collected data to the SCADA system, supervising and managing production processes. The WObit company proposes SCADA PcVue system providing the users have very wide possibilities in the field of design and modern surveillance systems. More information about PcVue and WObit measuring devices can be found at www.wobit.com.pl and by calling 61 22 27 422.