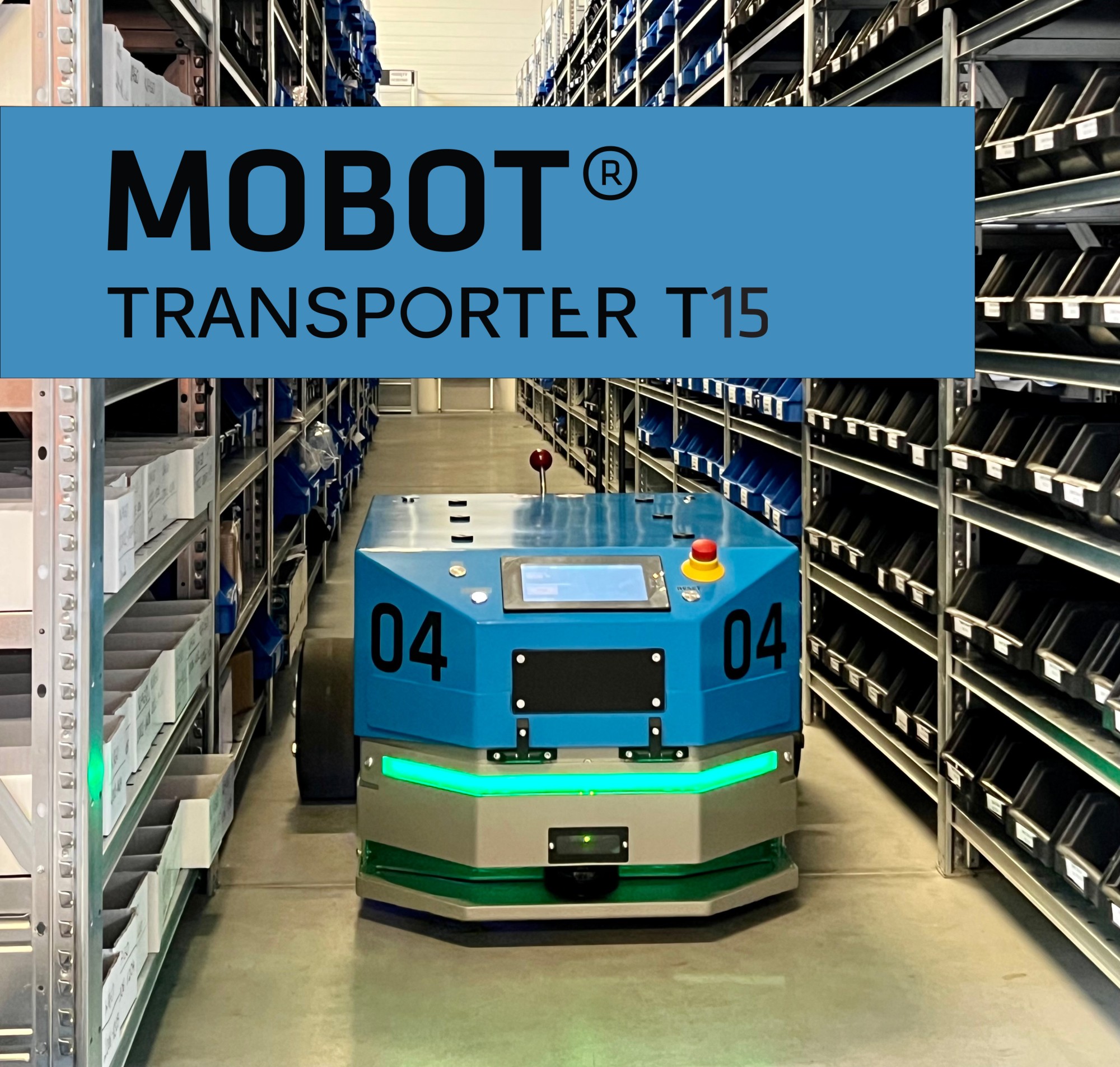

The WObit company introduces a new mobile robot from the MOBOT® TRANSPORTER series with a maximum towable weight of up to 1500 kg. The new robot has a robust, compact design with IP65 protection and is equipped with special sensors that allow it to work also outdoors.

The outdoor version allows e.g. transport of goods between production halls or warehouses. Thanks to this, the robot extends the possibilities of autonomous transport of various loads in logistics centers and production plants.

MOBOT® TRANSPORTER T15 gives you the ability to tow different trailers with different loads thanks to the interchangeable hitch. Trailers can be hitched/unhitched automatically or manually. If the load is changed or the robot is moved to another task, a quick change of the trailer is enough.

MOBOT® TRANSPORTER T15 is designed to perform the heaviest and most monotonous tasks, thus improves the ergonomics of human work.

The new MOBOT® is equipped with an innovative wireless inductive charging system that allows charging during the process. This ensures even greater efficiency, time savings and security.

Importantly, TRANSPORTER T15, like other MOBOT® robots, works automatically, precisely, with controlled navigation and speed, thanks to which it ensures smooth and careful transport of goods.

MOBOT®< /sup>TRANSPORTER T15 has implemented LMS laser navigation, using naturally occurring terrain objects, thanks to which does not require additional infrastructure to navigate and move around in space. LMS navigation provides autonomous traffic with a high degree of adaptability. This means that it can be implemented for a variety of applications, not just for industrial or warehouse robots.

The robot avoids obstacles on its route, and in the case of a very dynamically changing environment, it can be additionally equipped with 3D sensors placed on a special mast that will allow its reliable, collision-free operation.

In addition to LMS navigation, the robot can be additionally equipped with vision cameras that will ensure very high positioning precision up to 1 mm. This is useful when docking.

The technology of MOBOT® collaborative transport robots is flexible, easy and quick to implement, as it does not require costly changes to the factory and warehouse space, it is also scalable. This means that the solution can be expanded as needed and adapted to the growth of the enterprise.

Wherever you need to speed up processes, improve the efficiency and safety of transporting heavy loads, it is worth introducing robots MOBOT® TRANSPORTER T15 for carrying out transport tasks.