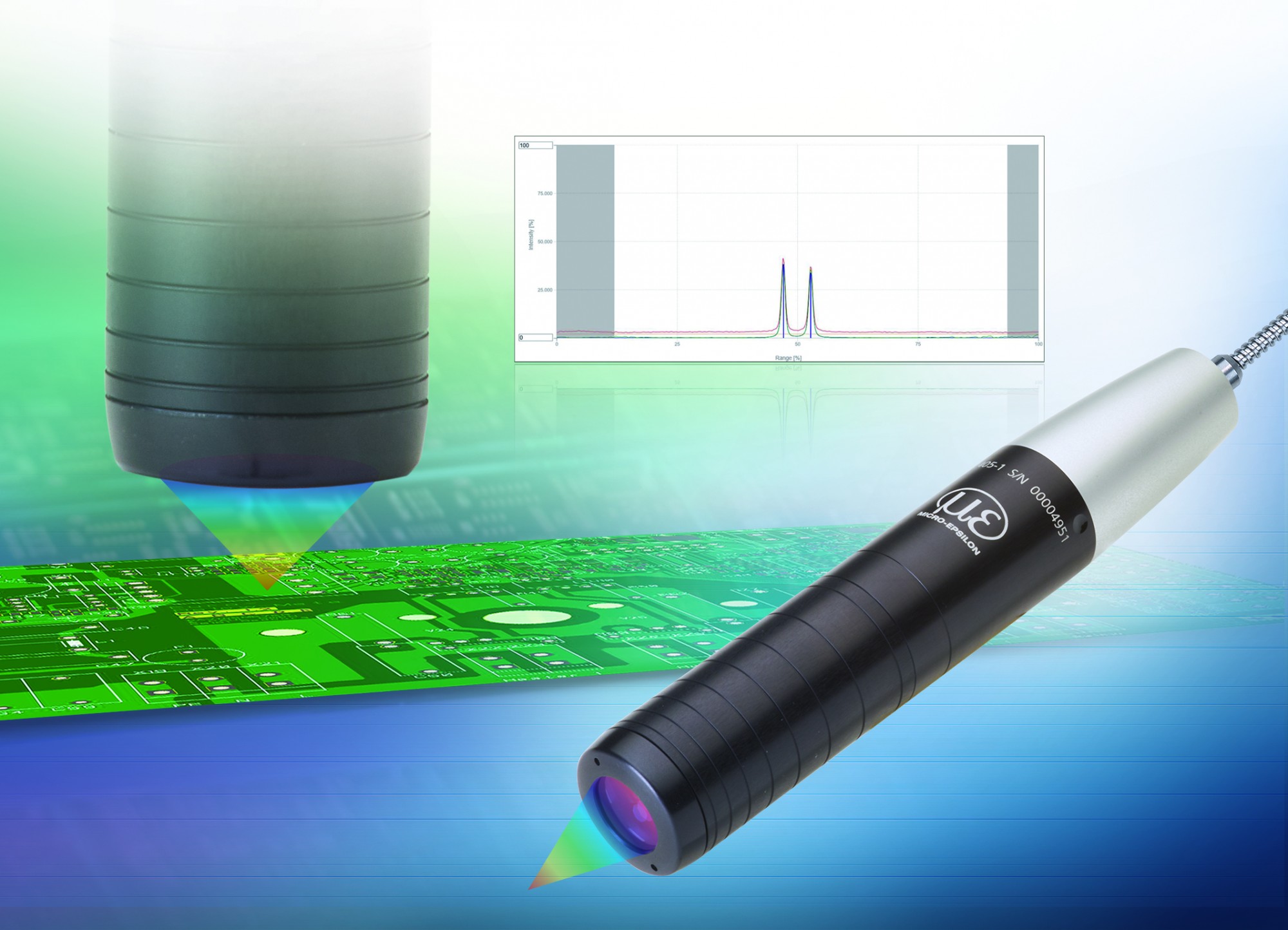

In order to protect the printed circuit boards from the negative influence of the environment, they are covered with a protective varnish. In some applications, including in the automotive industry, a minimum thickness of this coating is required. So far, it has not been possible to perform this measurement without destroying the test object. Micro-Epsilon confocal sensors solve this task in a non-destructive manner, without physical contact with the wafer, and give the coating thickness in real time. An example is the confocalDT IFS 2405 model with a measuring range of 1 mm.

It is characterized by an extremely small measuring spot diameter of only 8 µm and a high accuracy in measuring thin films. Thickness measurements, carried out in cooperation with the confocalDT controller IFC2461, are performed in a short time with a frequency of 1 kHz. Thickness differences, e.g. during the curing process, can be made visible by scanning larger areas. The measurement result is not affected by the type of substrate, the presence of copper tracks or passivation layers. The measurement is carried out at freely defined measurement points in specific zones.

Since the refractive properties of the lacquer depend on the hardening and solvent content, the refractive indices are pre-determined using a micrograph. Based on the measurement results, the process parameters of the automated painting line can be corrected, which reduces the number of production rejects.

See our products

confocalDT IFC2471 HS

confocalDT IFC2471 HS confocalDT IFC2451

confocalDT IFC2451 confocaIDT IFS2405

confocaIDT IFS2405 confocalDT IFS2407-1.5 Confocal sensor

confocalDT IFS2407-1.5 Confocal sensor Confocal sensor confocalDT IFS2407 / 90-0.3

Confocal sensor confocalDT IFS2407 / 90-0.3 Confocaldt IFC2411 confocal sensors controller

Confocaldt IFC2411 confocal sensors controller confocalDT IFS2406

confocalDT IFS2406 confocalDT 2421/22

confocalDT 2421/22ConfocalDT IFS2404 / 90-2 confocal sensor

Controller for confocalDT IFC2465/66 confocal sensors

Controller for confocalDT IFC2465/66 confocal sensors ConfocalDT confocal sensor IFS2407-0.1

ConfocalDT confocal sensor IFS2407-0.1 ConfocalDT IFS2404 confocal sensor

ConfocalDT IFS2404 confocal sensor confocaIDT IFC2461

confocaIDT IFC2461 confocaIDT IFS2402

confocaIDT IFS2402ConfocalDT IFS2407-3 confocal sensor

confocaIDT IFS2403

confocaIDT IFS2403