Industry, agriculture, research laboratories, infrastructure and many other fields today could not function efficiently without devices controlling the mass of the detail. The key element of such devices are strain gauges force sensors popularly called force sensors > or strain gauges. Resistance sensors are most widely used, which have many advantages such as high sensitivity and accuracy, small dimensions, resistance to vibration and shock, and the ability to work at high temperatures and pressures.

The most common are ready-made sensors in the form of a foil strain gauge stuck to the housing. Depending on the design of the support element (housing), such a sensor can be used to measure small forces in the ranges of single newtons, as well as huge forces in hundreds of kilo newtons.

The WObit offer includes force sensors in the version with built-in electronics (0-10 V, 4-20 mA or 0.5-4.5 V output) and without built-in electronics (output signal determined by a characteristic constant expressed in mV / V).

Construction and working principle force sensor

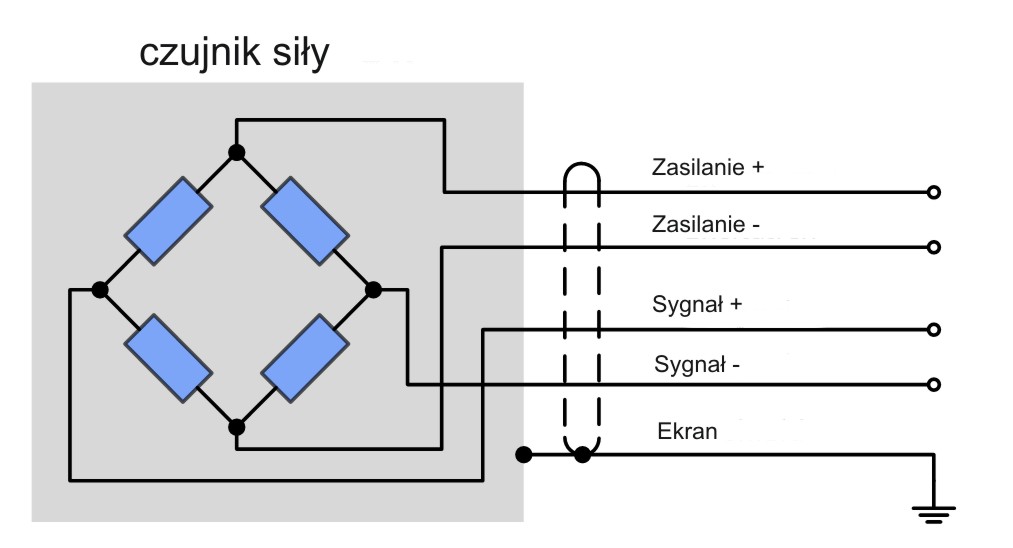

The force sensor has a spring body, usually made of stainless steel or aluminum. Measuring elements are glued to the body, so-called strain gauges. The strain gauge parameter is the electrical resistance, which changes its value as a result of a mechanical change. The force acting on the body is therefore transformed into a change in electrical resistance. There are usually four strain gauges on the spring body and they are connected in an electric bridge (Wheatstone bridge, strain gauge bridge). The connection diagram is shown in Fig. 1.

|

Fig. 1. Connection diagram of the force sensor. |

When using a force sensor with a strain gauge bridge in practice, it is necessary to ensure: 1. supplying the sensor with a constant voltage of time constant and 2. increasing the output voltage, which is usually very low, usually reaching from several dozen µV to values of 10-20 mV. This is possible thanks to the use of external signal amplifiers or special cards for a PC or PLC.

Sensors without a signal booster

WObit proposes strain gauges with a very wide measuring range, starting from 0-10 N ( KM200 ) up to 2000 kN ( EMS130 ). Depending on the series, sensors outside the measuring range differ in body shape - round sensors are available ( KMM30 , KMM50 ), beam ( KM701 , KM801 ), as well as S-shaped > ( K1505 , KM500 ). For measuring compressive and tensile loads, cylindrical sensors ( EMS150 ), round with threaded out ( KMM20 , KMM40 ) and S -shaped ( KM1506 , KM1603 ).

Cooperating devices

The most popular amplifier for strain gauge force sensors is WDT11. Thanks to the digital converter, the system allows you to precisely measure the force and convert it into an analog current signal 4-20 mA or voltage 0-10 V and digital (RS485). The built-in RS485 interface with the MODBUS-RTU protocol allows direct communication of one or several modules with the PLC or HMI panel. It is possible to connect up to 32 modules on one bus.

For applications requiring the use of several sensors, we recommend 4-channel ADT42 module. Thanks to the use of a precise 20-bit converter, the device allows for very accurate measurement of forces.

MD150T measurement indicator. This module allows you to make measurements with a resolution of up to 0.001% in relation to the range. The result can be scaled to any force or mass unit.

Both ADT42 and MD150T enable archiving of measurements carried out to a CSV file thanks to free applications ADT42-PC and MD150T-PC. Recording on a PC is carried out via USB communication to a computer with Windows.

Force sensors with built-in amplifier

Another option is to build a signal amplifier directly into the sensor. A sensor with a built-in signal amplifier has the same mechanical properties as a standard sensor. However, it does not require any other components to be used and after connecting to the supply voltage the signal can be applied directly to the input of the AD converter. The internal structure of such a sensor is shown in Fig. 2.

|

Fig. 2. Force sensor with a built-in signal amplifier. |

Sensors with a built-in signal amplifier are also offered by WObit. There are new sensors available in the offer type KMM20e , KMM40e and KMM50e , all with built-in signal amplifier. The built-in signal amplifier used in the sensors is EMS165.

Force sensors KMM20e , KMM40e and KMM50e

These membrane sensors are designed for universal use. They have a simple design and are made of stainless steel or aluminum. They can be used to measure tensile or compressive force (except for KMM50e ). The built-in EMS165 signal amplifier is powered by 5 VDC, so it is possible to power the sensor via USB. This is an advantage especially in computerized measuring systems. Therefore, they are mainly used in testing laboratories or in testing machines.

Parameters KMM20e , KMM40e and KMM50e

Measurement range

- KMM20e 100 N… 5 kN

- KMM40e 1… 50 kN

- KMM50e 100 N… 500 kN

Supply voltage 5 VDC ± 5%

Output voltage:

- Load in one direction

(compression or stretching) 0.5 V… 4.5 V.

- Load in both directions

(compression and stretching) 0.5 V… 2.5 V… 4.5 V.

|

Fig. 3. KMM40 force sensor (KMM40e). |

If the article interested you and you see the need for strength control or weight measurement please contact our specialists . They'll advise you which sensor is right for your application. Contact here.