In industry, significant amounts of energy are used to feed a variety of manufacturing processes. When looking for savings and ways to increase the energy efficiency of an enterprise, it is worth paying attention to the drives used in production machines.

Machine drives consume a lot of energy used by companies, so when modernizing a production line or making new investments, it is worth taking care to use modern engines, such as drives with electronic commutation (BLDC). They are more and more often used because of the very high energy efficiency , they have a higher range of speed, they are also devoid of mechanical constraints caused by brushes - thanks to which they have a much longer lifetime.

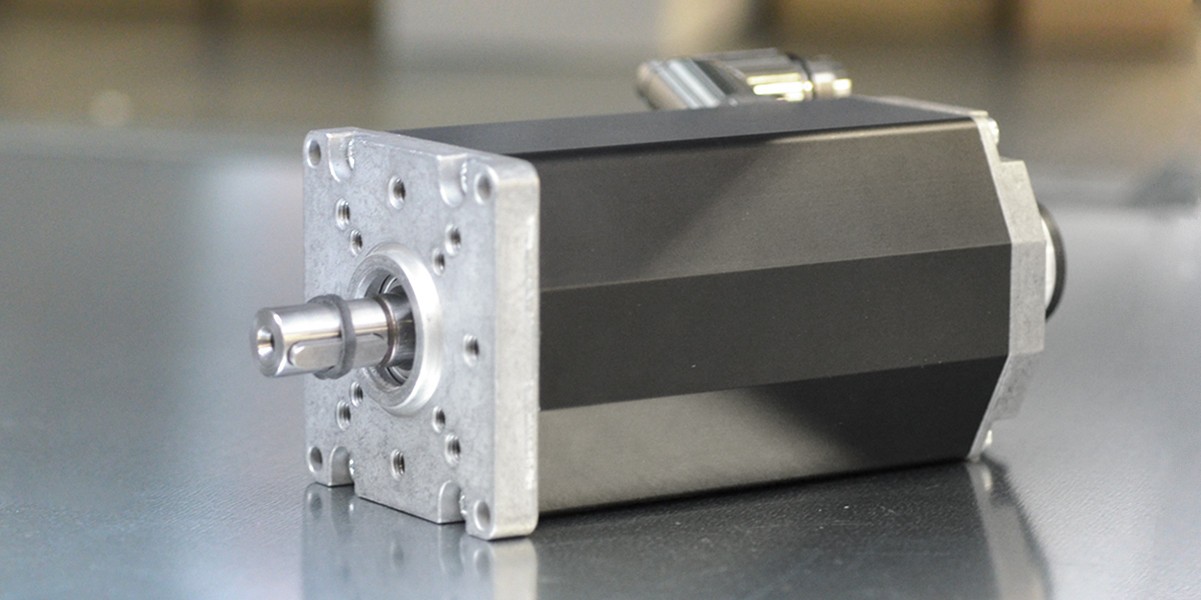

BLDC engines also have better torque characteristics that allow operation over the entire speed range with rated load. Compared to brush drives, those with electronic commutation have better thermal characteristics, which is related to the positioning of the windings on the stator, which is connected to the casing, thanks to which the heat is better dispersed. Compared to induction motors, they are characterized by higher efficiency and power density, with smaller dimensions and weight.

The WObit company offers a wide selection of brushless DC motors produced by companies: ElectroCraft (RP series and LRPX), Nanotec, Dunkermotoren ( BG series ) and Buehler Motor ( series 1.25 .xxx.xxx ). They are made for operating voltages from 24 to 325 V, rotational speeds from 500 to 14000 rpm, reaching the rated torque from 2 to 290 Ncm. The range of available powers is 5 to 1100 W.

ElectroCraft brushless motors have a compact construction, and at the same time high rated torque (up to 221 Ncm). Thanks to good parameters, they will prove themselves in applications requiring sudden acceleration and high positioning accuracy in industrial automation, medical or military industries. Among the four series, it is worth paying attention to the very efficient LRPX motors, which achieve peak efficiency at low rotational speed, allowing integration with a planetary gear. |  |

They are characterized by a large torque with a small construction and low power consumption, as well as quiet operation due to maximum efficiency at low rotational speed. A RPX series with a very compact size while maintaining high torque is suitable for medical, measuring or military equipment. However, mobile robotics are ideally suited for RP series with high efficiency. It is worth paying attention to the RP34-221-V24 engine with a rated torque of 221 Ncm powered by 24 VDC.

Among the brushless drives manufactured by Nanotec, the interesting series are flat motors for applications requiring high precision and small external dimensions. They have permanent magnets placed on a special ring attached to the rotor, rotating around the inner stator with windings. At comparable torque, as in the case of motors with an internal rotor, these are characterized by a smaller torque variation due to a high moment of inertia. In addition, they can be closed in shorter housings.

In applications that do not require sensor monitoring, the DS16 series of slotless Nanotec engines will perform excellently. Traditional BLDC Blade motors have a winding placed in the pivots inside the stator. In contrast, pluggable BLDC motors have only ring-shaped inserts, devoid of an iron core, which performs stator function. A flat, glued or cast winding is added to this. Nuclear motors of Nanotec offer higher speeds than standard BLDC motors. Due to the removal of the iron core, the inductance of the motor is very low and the current in the winding increases very rapidly. In addition, there is no loss in iron, making the motors more efficient. No torque is present during slow operation. Thanks to the lack of magnetic field enhancement by the iron castings as in the standard BLDC motors, there is no latching torque. In addition, at low speeds, the engine runs very evenly. This type of engine is ideal for applications that require high rotational speeds and work in a variety of environments, eg in medical applications.

Engines from the 1.25.xxx.xxx series Buehler Motor is a solution that, thanks to its compact dimensions and high rotational speed, performs well in vending machines, ATMs and banknote counters. This series can be adapted to the requirements of the application by mounting the encoder or brake, adjusting the rotational speed, changing the winding, as well as modifying the length of the shaft on both sides, other bearing, adding gear wheels or additional sealing to increase the degree of protection. |  |

Where it is necessary to use motors with a controller, consider the implementation of electronically commutated BG series motors Dunkermotoren, which can have integrated controllers with different functions. One of the simplest versions of the driver is the 4-quadrant speed controller (SI). In this embodiment, it is additionally possible to set the target speed by means of the analogue 0 ~ 10 V analogue input. Two digital inputs are available for four operating modes: left / right rotation, controller locking and stop with holding torque. A more advanced version is a motor with an integrated 4-quadrant cheese controller (PI), which is supplied with PC software that enables drive assistants. Thanks to this, it is easy to parameterize basic operating modes such as speed, moment and position.

Models BG45 to BG75are additionally equipped with a CANopen interface that allows you to change the most important trajectory parameters like position, speed and values of accelerations in real time. In the event that a different communication interface is required in the application, Dunkermotoren offers motors equipped with Profibus, ProfiNet and EtherCat. For design quantities, there is also a drive with an integrated motion controller with the Master function. It allows the construction of a stationary network without a PLC master controller. The motor is equipped with two connectors for connecting the network interface, power stage and logic, taking into account the user-defined digital I / O. Communication between several controllers is possible via I / O and the CANopen interface.

To find the optimal drive for your application and for more information, please contact WObit specialists.