Imagine a scene. You have designed a powerful propulsion system and all you need to do is connect the engine. The only problem is the sum of the tolerances in the housing and bearings indicating that the spindles are not exactly aligned. A rigid connection between them will increase the lateral force of the bearing and create more load than it was designed for the engine.

The last thing that many people think about when designing a system is clutch . Nevertheless, it is this tiny ingredient that must not only connect two assemblies, but also compensate for design errors and the operation of external conditions.

What is a coupling?

This involved a part or assembly of parts serving to connect two independently rotatably mounted drive (active) and drive (load) shafts to transfer the torque.

The clutch can be classified according to various criteria: tasks, construction solutions, the method of switching on or, for example, the type of torque link.

Different types of couplers are characterized by different torsional rigidities and the possibility of compensating for assembly imperfections between joined joints.

The basic parameter characterizing the clutch operation is the transferred torque, which depends on the transmitted power and rotational speed.

What should you take into account when choosing a clutch?

To choose the correct coupling, consider torque, shaft size, speed and misalignment first. Is the misalignment a corner, radial, axial or a combination of all three? How rigid must you have coupled in a shortcut to ensure the accuracy of the positioning of the shaft? And what about the work cycle? Does he have to work continuously or intermittently and what will be his work on the environment? What assembly method is needed? Pressure screw or clamp - or is a key needed?

Helpful in obtaining answers to the above questions is to perform the necessary calculations, as well as to familiarize yourself with the documentation of individual products.

What kind of clams do I have to choose from the WObit offer?

| SDZ disk and 2-disk SDZ clutches - The clamping rings are connected to a special alloy disk, which rigidly transmits the load torque, while ensuring certain elasticity in the axial direction. Disk clutches are best used in high speed positioning drives with servo motors. |

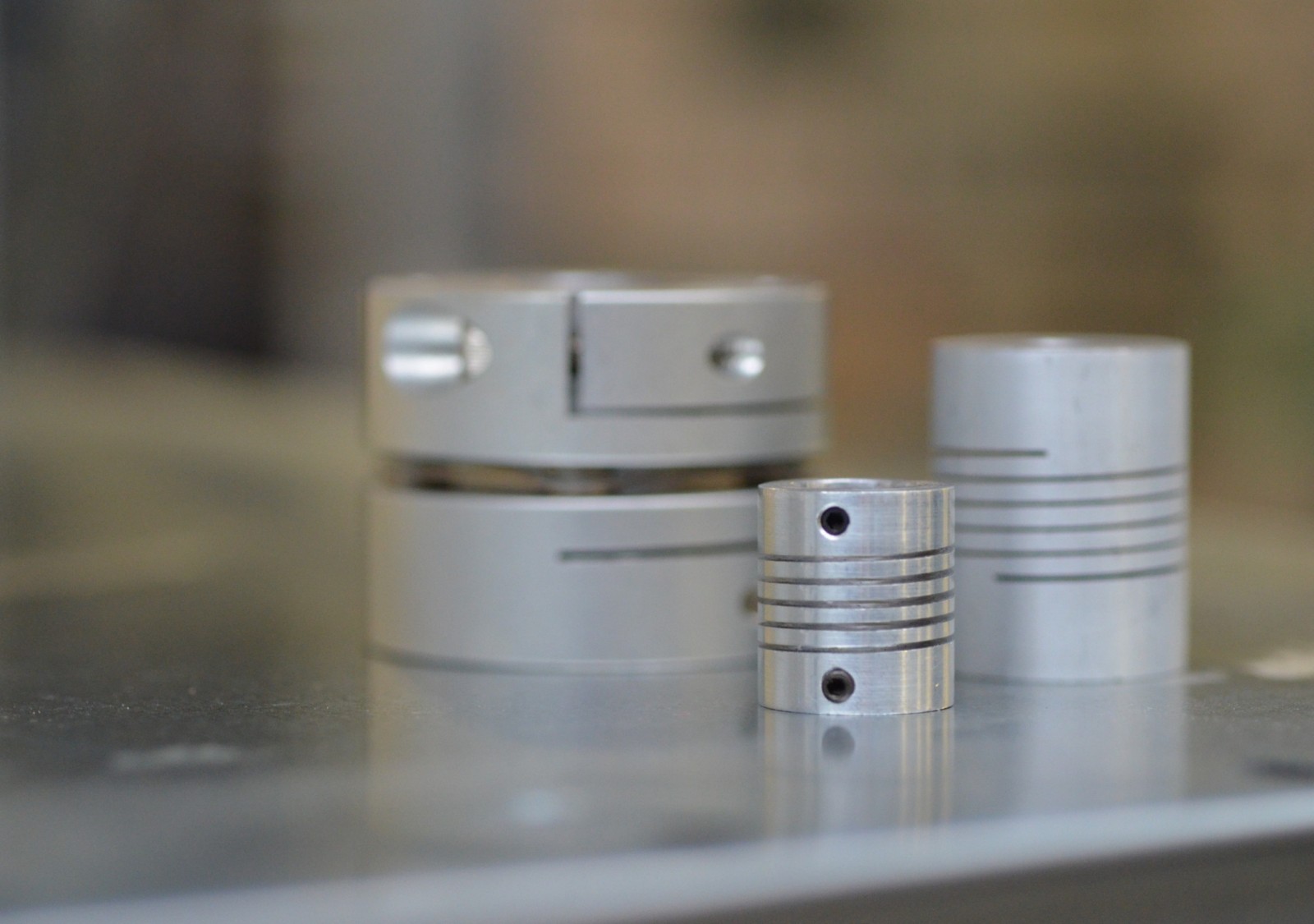

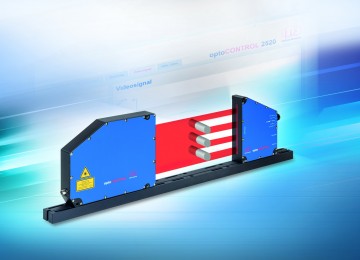

The helical aluminum SHZ and SHA clutches and SND aluminum cuttings - made of one piece of aluminum, they provide a lot of durability at a small moment of inertia and a relatively large moment transferred. The parameters of the helical coil and the thickness of the wall are selected so as to provide a small kinematic transfer error with the necessary flexibility in the other directions. Often used when connecting drive axes with an encoder. |  |

| OLDHAM couplings are comfortable in assembly, because three-piece. They consist of two clamping or pressing rings and a replaceable insulating insert that transmits the drive torque. The couplings are well-suited for small and medium drives, among others stepper motors and servo drives. |

Clashed SPD plastic couplingsthey are cheap clutches of electrically insulating glass-reinforced plastic having a low moment of inertia. Despite their compact design, they enable precise torque transfer while reducing axial and angular misalignment due to the inaccuracy of assembling the connected axes. |  |

| Bellow SMZ and SMD couplings, with attention to the high flexibility in the axial direction and bending, achieved thanks to the characteristic construction of the bellows, with the simultaneous high rigidity, are used to connect the encoder axis with the axis of rotation for high position precision. Separate bellows clutch lengths and number of turns that provide different parameters are available. This is a compromise between misalignment and shortitude. The greater the non-aligned alignment, the more you have to reduce the torsional stiffness. |

FLEX-P couplingsare made in a double loft made of molded plastic, permanently attached with steel or stainless steel rings, which gives a compact construction. Thanks to this, we obtain the excep- tional flexibility in all three axes. Ideally suited for carrying small rotations. They are characterized by low wear and quiet operation, although their low stiffness makes them less suitable for applications with high positioning accuracy. |  |

Who can help me choose clutch?

If you are doing the calculations and facing the product documentation, you are afraid and shudder get help. Surely you can return to the WObit specialists who have been supporting this topic for many years. If you are in doubt, please contact us .