Monitoring the course of technological processes is indispensable in order to ensure their correctness and stringency. One of the most frequently controlled parameters is temperature. This feature plays an important role especially in the production of plastics or glass.

Temperature measurements can be made by contact or without contact, but in the case of the production of glass, paper, plastic processing or welding, non-contact sensors will be much better tested. They use properties of matter that emit infrared radiation above the absolute zero temperature (-273 ° C). The detector in the sensor processes the transient infrared radiation into an electrical signal. The result is a linearized temperature value, which is further processed.

WObit company offers a wide range of Micro-Epsilon sensors among which there are both universal sensors and special solutions for a given application, as well as OEM sensors.

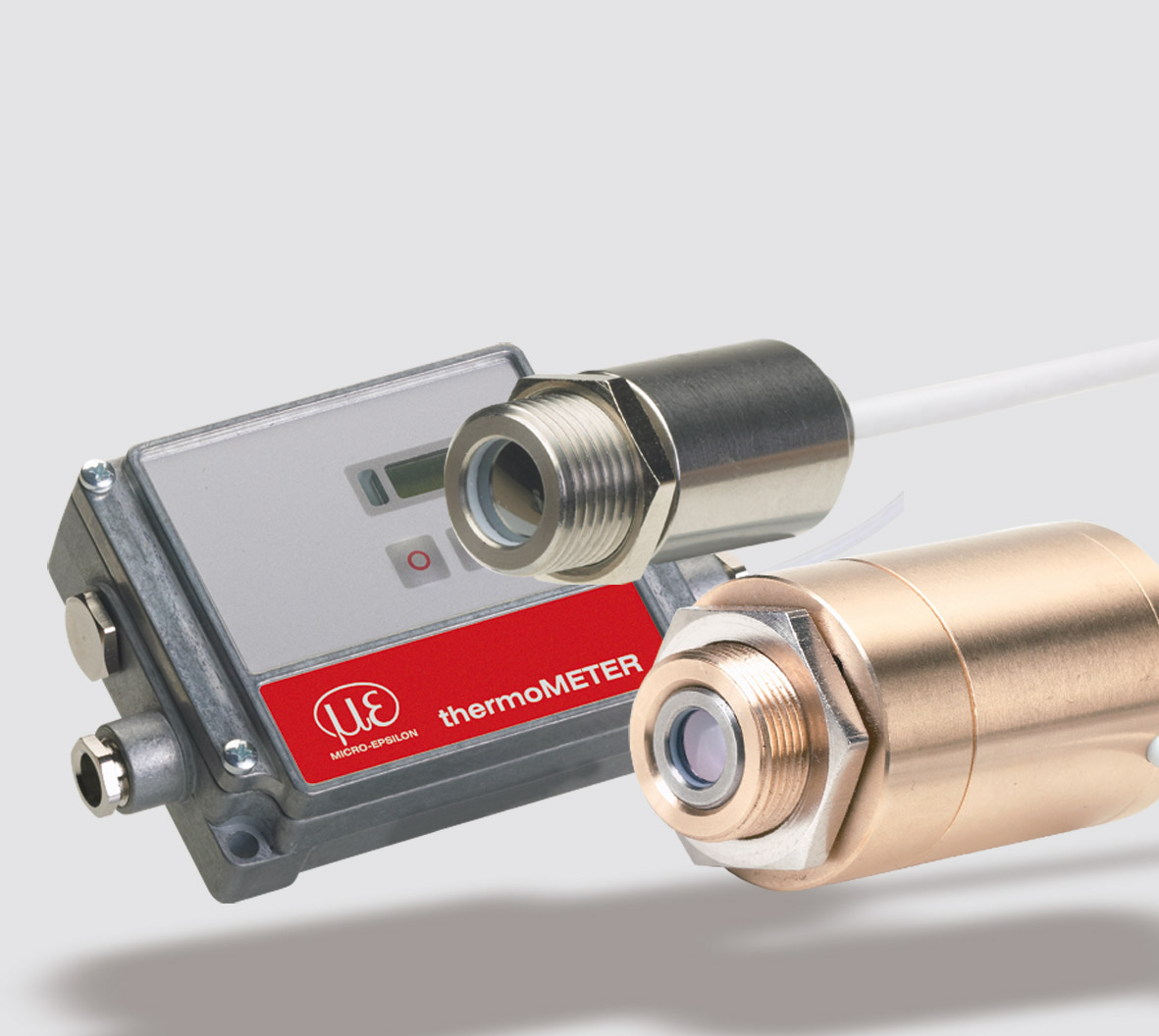

The most universal version of sensors is CT series whose standard measuring range is -50 to 900 ° C. Also available are those intended for use in the metal industry, which measure temperatures in the range from 50 ° to 2200 ° C. Sensors for measuring liquid metal have a measuring range from 1000 to 2000 ° C, while those for measuring the glass measure temperatures in the range from 100 to 1650 ° C. |  |

An interesting performance is the sensors for measurement of discomforts with optical resolution of 75: 1, which are equipped with a double laser sighting, showing the size of the measured surface. In CT series , there are also sensors for use in the environment dangerous, threatened explosion, with various exit standards.

| In metal or ceramic processing, well temperature sensors from the CSVideo series equipped with a laser sight and integrated electronics for video processing, which allows precise configuration of the sensor and, as a result, measurements of very hot elements in hard-to-reach places. A response time of 1 ms allows these devices to be used in fast processes. CSVideo series allows you to automatically capture images frame by frame, save data graphically, and save sensor settings to monitor the process. |

Functional group of products portable temperature sensors with a measuring range of -35 ° C to 900 ° C with a patented laser sight that is ideal for fast and mobile temperature measurement. It is worth to pay attention to thermoMETER P20 designed for temperature measurements of hot surfaces from 0 ° C to 2000 ° C from a safe distance (up to 12 m). Thanks to the wide spectral range and the dual laser sight, precise and simple measurements are possible. The equipment consists of a USB interface and internal memory of up to 2,000 measuring values. In addition to evaluation and monitoring functions, the included software provides oscilloscope function for 20 measurement values sec.

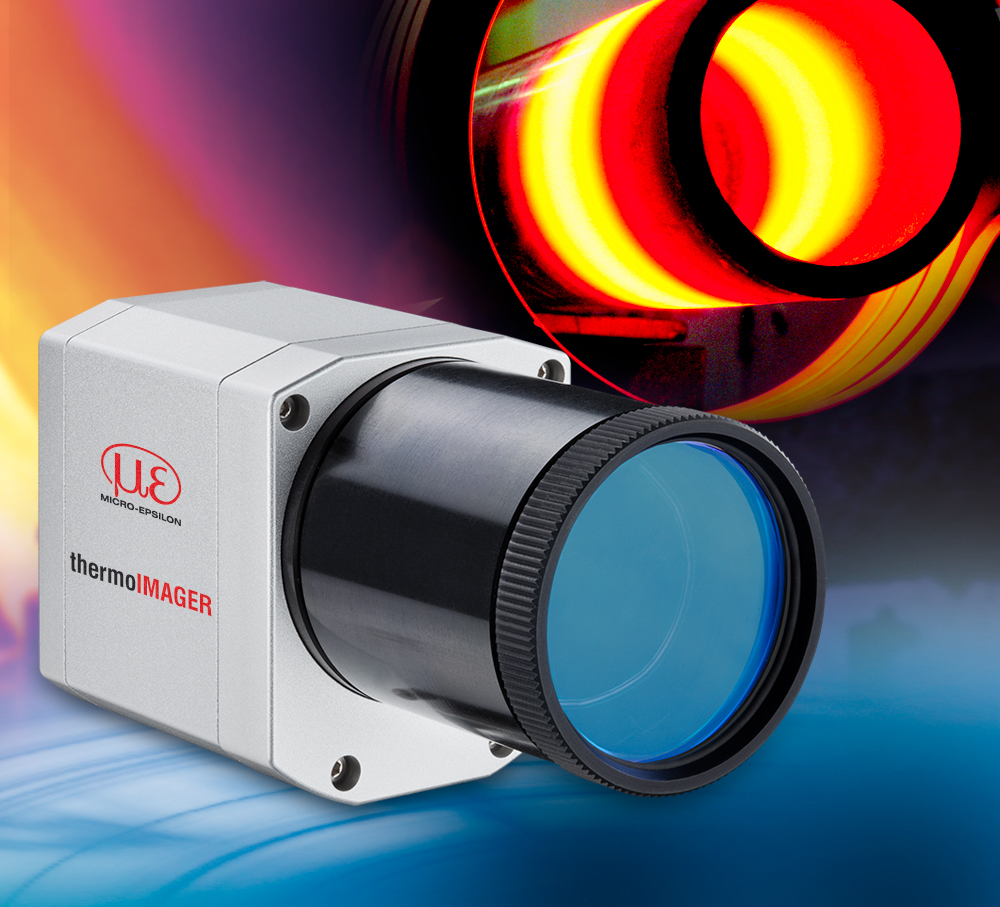

In addition to the various temperature sensors, WObit also proposes thermovision cameras , which are perfect for applications requiring temperature analysis of the tested surface. The cameras have been equipped with a popular USB interface that allows them to be powered from the PC's port at the same time. An additional advantage of cameras from the thermoIMAGER TIM series they are small in size and low in weight, which allows you to mount the camera in a limited space. Depending on the distance from the object being measured and its dimensions, we have several interchangeable lenses available. TIM200 series cameras additionally equipped with a daily camera for regular registration image. Different performance classes of available cameras allow you to use the appropriate model in very diverse applications.

The smallest thermal VGA camera TIM640 provides thermal image in real time with an optical resolution of 640x480 pixels. It allows you to record images with a resolution of 640x480 pixels and a speed of 32 fps. The camera is characterized by a large optical sensitivity of 75 mK, making it possible to record very small temperature differences, which is indispensable in many thermographic applications. In the ambient temperature range from 0 to + 50 ° C it is able to measure the temperature of objects from -20 to + 900 ° C.

ThermoIMAGER TIM640 finds use when thermal analysis of objects moving on fast conveyor belts, for detection of hot spots and defects without affecting measured objects, injection molding, semiconductor components production and functional tests of assembled PCBs. It allows any user to define temperature measurement points on the recorded image along with the registration of the minimum, maximum, average value and the possibility of generating alarms. The camera is supplied with TIM Connect software for monitoring, measurement and image editing documentation as well as DLL, ComPort and LabVIEW drivers.

Especially for measuring the temperature of metals, especially in the hardening and rolling of steel, but also in the processes of processing graphite and ceramics was prepared thermoIMAGER TIM M1 camera . It can measure temperature in the range from 450 to 1800 ° C. ThermoIMGAGER TIM M1 camera it is equipped with a CMOS detector that allows you to achieve unprecedented image dynamics with a maximum resolution of 764x480 pixels and frequencies up to 32Hz. In the case of fast processes, you can switch the resolution of 72x56 pixels at 1000 Hz, and also use it as a fast pyrometer. |  |

The device intended for use in the glass industry is camera thermoIMAGER G7 . It has a spectral range of 7.9 ľm, which allows stable measurements of even thin glass sheets. If the glass has anti-reflective coating, an additional pyrometer can be integrated in the camera to adjust the camera. Similarly to all cameras from the thermoIMAGER TIM series, model G7 has analysis software that allows you to monitor thermal processes thanks to the linear scan function, even if the field of view is limited.

The use of portable or integrated in the application of IR temperature sensors opens up various possibilities of measuring and displaying temperature changes in the field of quality control, automation systems, production processes, maintenance of machines and large objects. We invite you to visit the www.wobit.com.pl website, where you will find more information about the devices and the possibilities of their use.