Paper production, printing or production of metal sheets require the use of various types of rolls or cylinders. To receive a high quality product it is necessary to properly set the rolls and use rolls without defects. The Tekscan company has prepared NPAT system dedicated to this type of application.

Why did you measure the rolls?

Manufacturers of paper, metal sheets and printing companies know perfectly that precise alignment of rolls is a key condition for obtaining a high quality product. In addition, in the case of paper production, when the roll setting is incorrect, the use of such elements as a dryer or cylinder liner is much faster, which in turn significantly increases the costs associated with the frequent replacement of components.

In addition to the uneven positioning, the surface of the rollers is equally important, which, if used up, can be subject to various deformations, such as stiffness, saddle-making or creating characteristic thresholds. The shape errors of the rollers of the rollers become a barrier to their free travel along the axis of rotation, and the produced sheet metal or paper does not meet the expected quality standards. The way to check the correctness of the rollers and their surfaces is to measure these elements.

How did you complete the measurement?

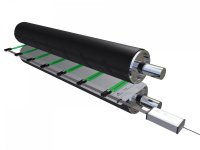

The solution proposed by WObit is NPAT system ( Nip Pressure Alignment Tool). It is a complete tool for measuring the pressure distribution between the rollers. Thanks to it, we gain the ability to perform fast and accurate measurements, while solving problems with misalignment and uneven distribution of forces.

NPAT consists of a sensor (configurable size up to 10 m) and electronics together with software. The system measures and clearly displays the results in real time, informing the user about the pressure distribution of the measured contact area of the rollers into the length and the width of the roll. The obtained data guarantees correctness of the production process, maintenance, quality control and proper setting of rolls. | .jpg) |

The system uses patented thin-film, tactile force sensors with a thickness of only 0.625 mm, which easily fall into tight spaces. These sensors have the form of a matrix, which is why they are called measuring mats. Each mat is composed of individual measuring points (so-called senseli) - the highest resolution mats have as many as 248 senles per 1 cm. The Tekscan pressure sensors have a ~ 5 microsecond response time, providing almost instantaneous data transfer.

In the case of the NPAT system , several such sensors are placed at equal intervals on a flat foil backing. An electronic part is connected to each sensor, which is an Evolution Handle sensor holder. It enables connecting a foil pressure sensor with a PC via the USB port - this holder has an integrated USB cable. In the NPAT system, these handles are connected by a ribbon cable, which has a USB connector for connecting to a computer. The electronic part collects information from the sensor and sends it in digital form to the PC computer where Tekscan software is installed.

Software

.jpg) | The NPAT system is sold with the I-Scan Test software. It contains the force / length units and the result presentation function in the form of a graph, thanks to which it is easy to display the measurement results from individual sensors. The I-Scan Test software has the basic functions necessary to check the uniformity of rolls. The system clearly shows the pressure distribution, the imprint of the contact area between the rollers and the area along the roll (pressure along each sensor). |

Each sensor band in the NPAT system is a single column in a row that measures the relative pressure distribution along the roll contact area. The various configurations of NPAT sensors allow you to measure different lengths and the total space between the rollers. Real-time software displays the pressure distribution along each sensor and can save a snapshot / photo based on which graphs presenting the pressure distribution are created. It is possible to compare the recorded data with the current measurement in real time. The I-Scan Test also shows the average and maximum pressure along the sensor, thanks to which the user can easily adjust the rollers by moving them on the machine.

The NPAT system , like other Tekscan measuring systems, is characterized by durability and the possibility of repeated use, it is easy to configure and portable. It provides countable and reliable data, thanks to which the user can correctly set the rollers, thus the maintenance and settings are carried out efficiently, and the circular product has a fixed, high quality.

We invite you to visit www.wobit.com.pl to find out detailed technical data, you can find there information on the remaining Tekscan measuring systems for .in. for measuring the pressure exerted by the person on the seat, gripping objects, the pressure exerted by the tires, as well as the universal I-Scan system.