Eddy current sensors is a solution designed for precise measurements of displacement, distance and position of objects conductive currents in harsh industrial environments.

Thanks to their possibilities, they can be used, among others for measuring the thickness of a detail.

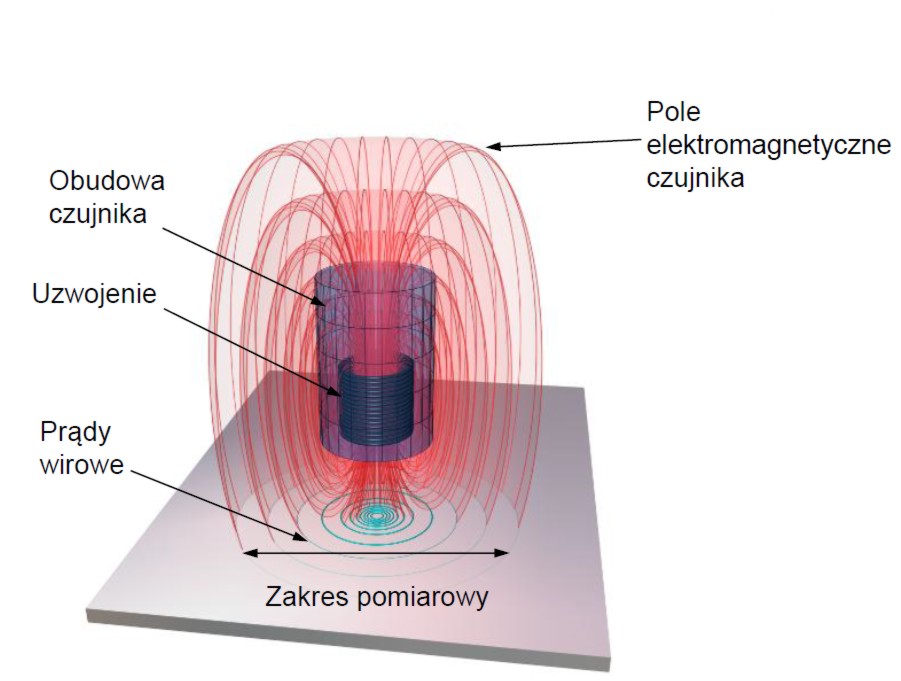

Basis of operation

Eddy current sensors use this dependency to perform non-contact distance and position measurements. Measured objects may have ferromagnetic and non-ferromagnetic properties.

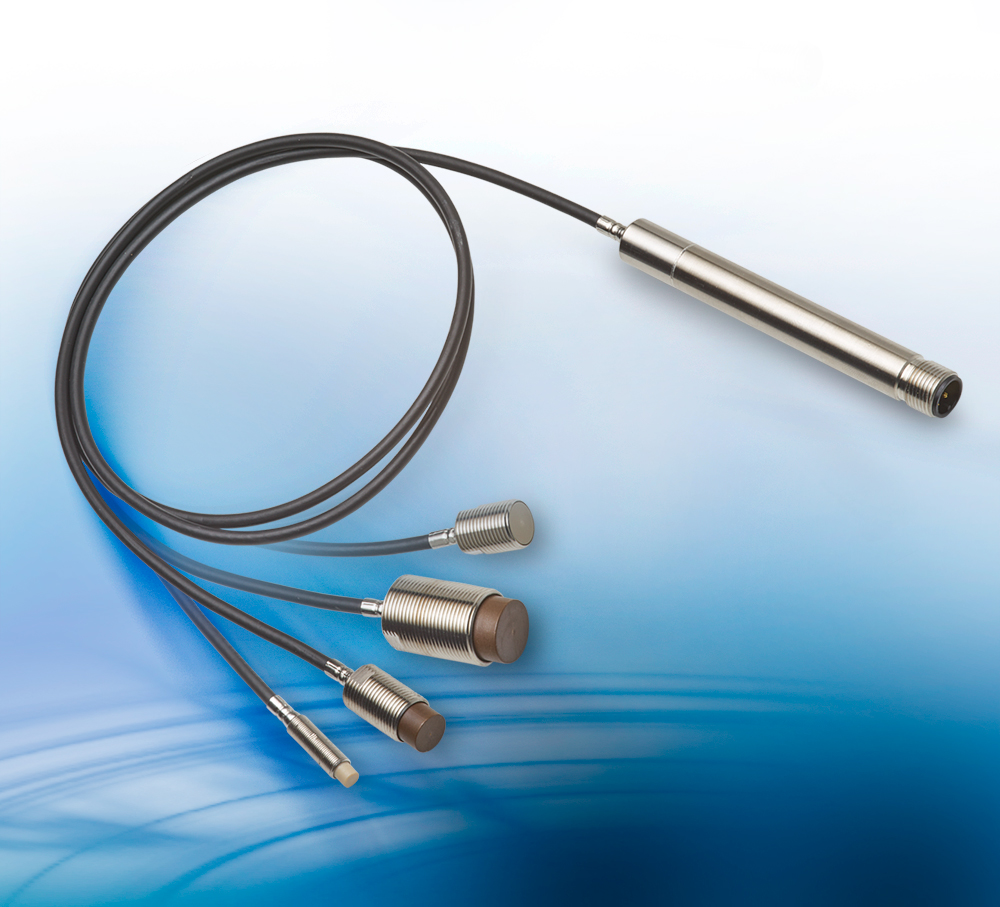

Eddy current sensors are characterized by high resistance to oil, dirt, dust, moisture etc., thanks to which they are ideally suited for use in harsh industrial environments. Due to the non-contact method of measurement, they do not use themselves mechanically. It is also worth paying attention to their various versions, the smallest sensors have a diameter of only 2 mm.

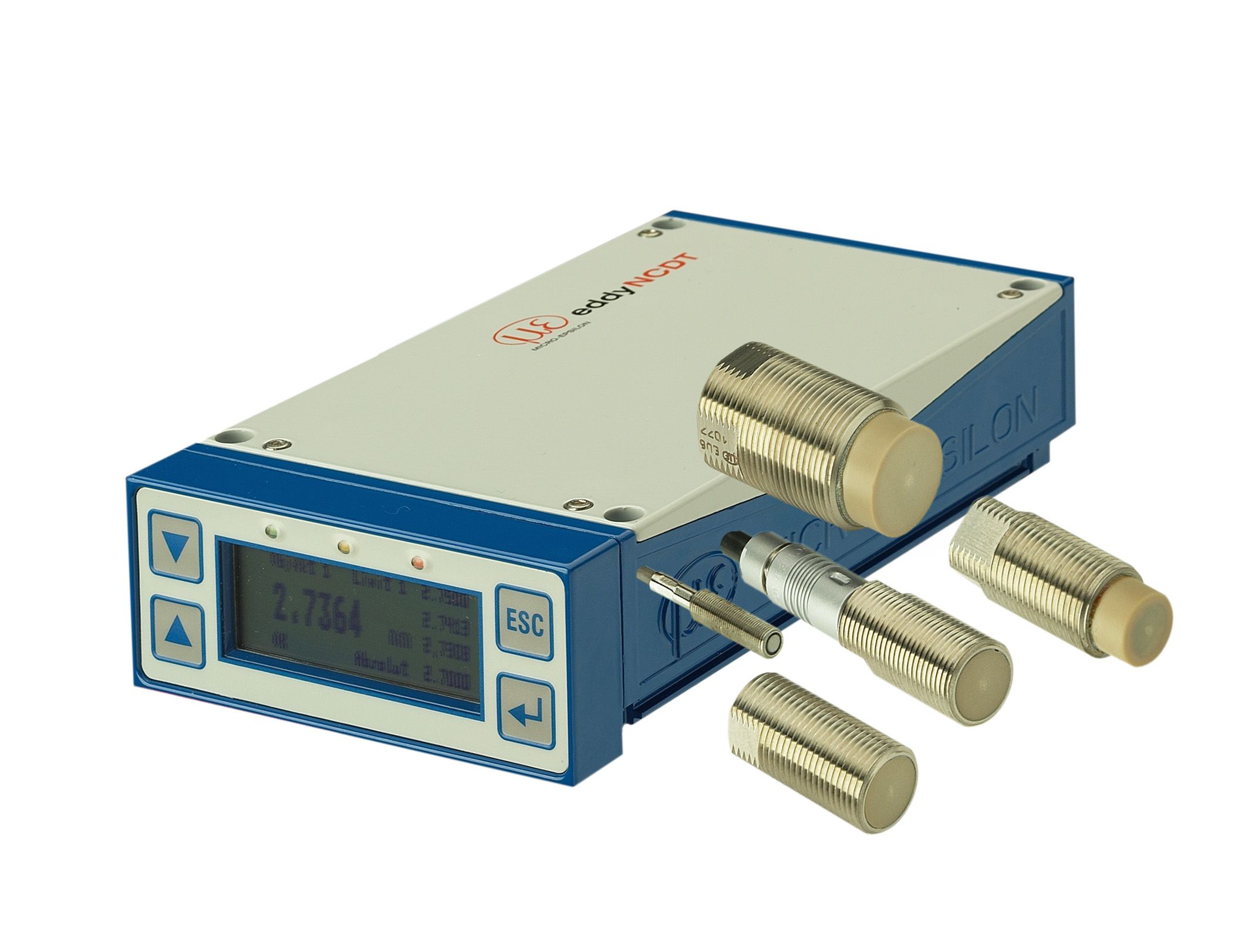

| The WObit offer includes a new eddy3005 measuring system with integrated electronics with compact dimensions. The temperature compensating design ensures high stability even in environments with variable atmospheric conditions. Due to its pressure resistance, temperature stability and compact design, eddyNCDT 3005 is ideal for use in harsh outdoor environments. |

Thickness measurement

One of the applications in which eddy current sensors were used was to measure the thickness of the sheet. Eddy current technology has been chosen for its high resistance to external factors, including pollination, which disqualifies the measurement with the use of laser sensors. In order to realize the thickness measurement, two sensors were used in a differential circuit.

The differential measurement consists in combining two synchronously acting sensors with each other and subtracting the values measured by them from the distance between them. Thanks to this solution, when the measured object moves within the measurement field, the measured value does not change, because constant compensation occurs.

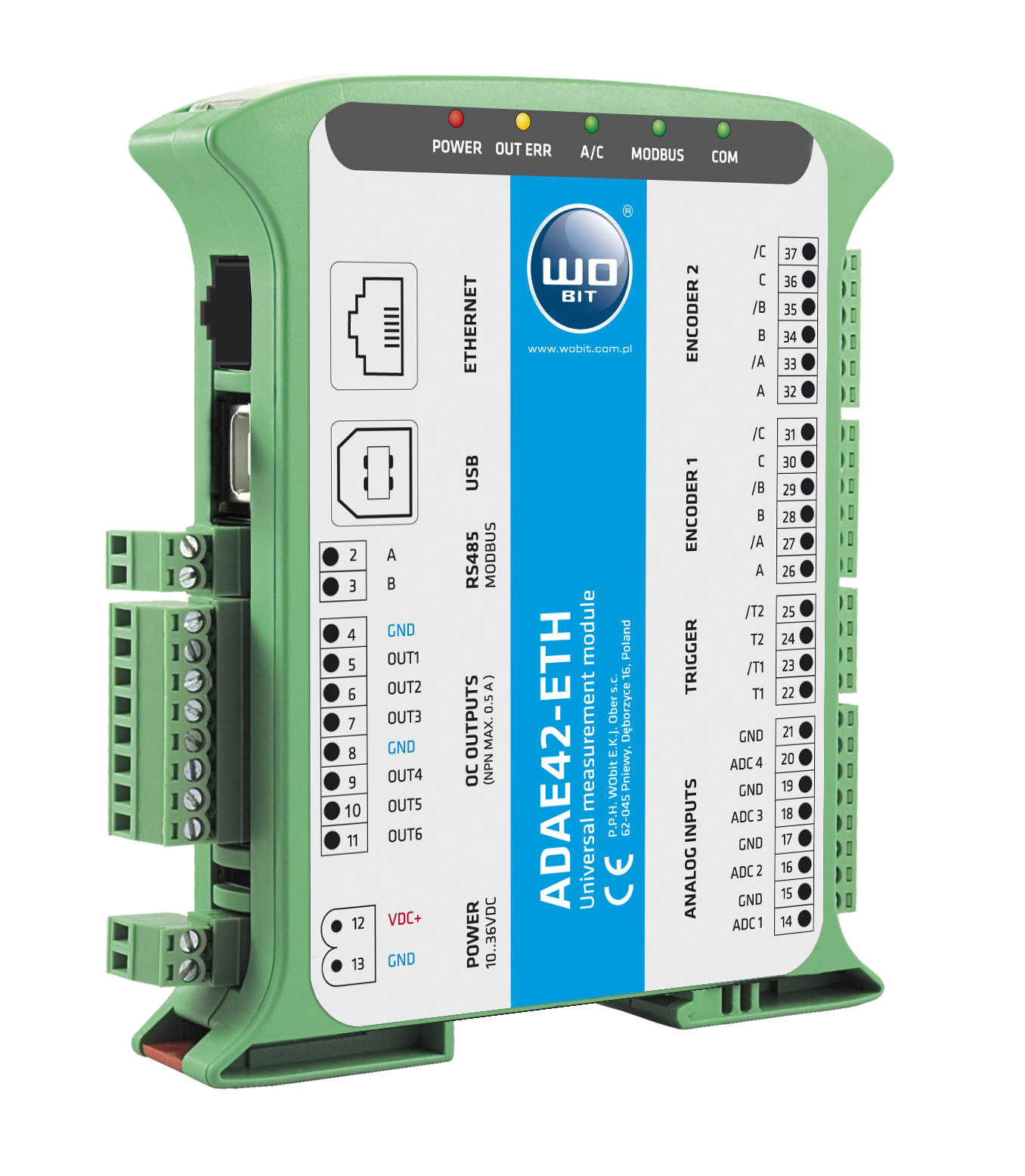

The measurement results are collected by multi-channel measuring module ADAE42-ETH . The module supports up to four sensors with an analogue output and two sensors with a quadrature output. ADAE42-ETH is equiiped with USB, RS485 Modbus RTU and Ethernet interfaces, enabling intuitive configuration of the device and data aquisition from PC. The free application allows you to record the measured quantities in real time, and save measurements to a file and parameterization of the module. Due to Modbus RTU interface it is possible to simultanoulsy connect many modules and data collection from bigger number of sensors. |  |