The most important trend on the market is the idea of Industry 4.0, based on the use of digitization of production ensuring the integration of systems and global access to data and machines, automation of manufacturing processes and cooperation of machines and people.

It covers a number of new technologies necessary to ensure the competitiveness of Polish enterprises.

By definition, this means transferring the process management burden to control and control systems such as ERP / SCADA.

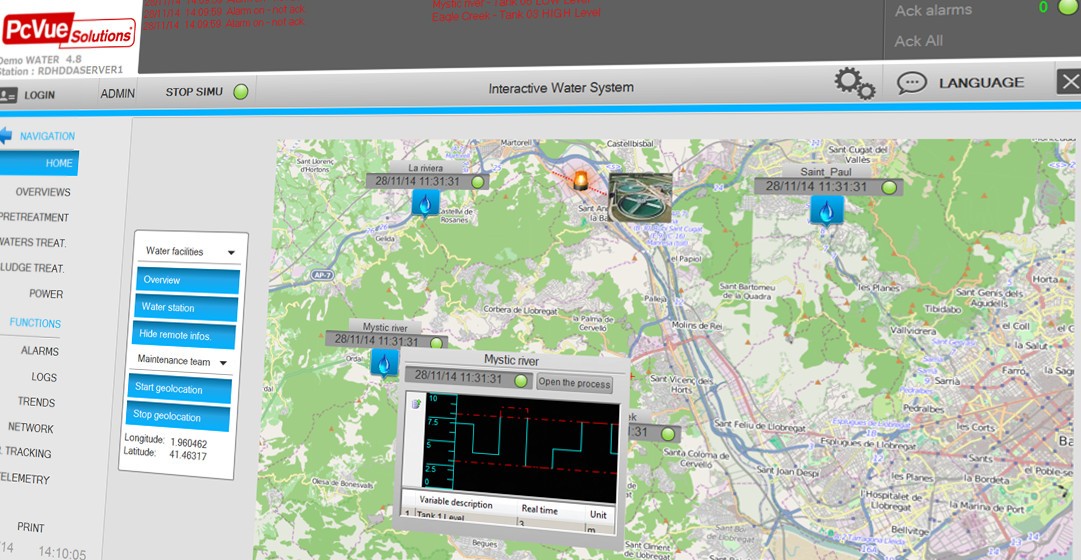

Modern SCADA systems have more and more complex modules for reporting and data analysis. They are also increasingly often integrated with the company's management and control systems.

They allow you to analyze data, thanks to which you can create process simulations, and also use more efficiently available resources.

In the longer term, it allows to increase the level of safety of these processes and to reduce losses in emergency situations (when it is known in advance, where the highest load and consumption occurs).

Current SCADA environments also offer global access to the factory from anywhere in the world and provide a quick response to events.

Thanks to the extensive control and monitoring functions and the analysis of a large amount of data, managers can make key decisions faster and operators are significantly reduced in their daily duties.

Simplicity and ease of use are also important thanks to the intuitive graphical interface. Thanks to this, the user can quickly and unequivocally interpret the messages reported by the system and react to them.

Simply moving around in modern SCADA environments does not require long-term training.

Implementation of the SCADA system in the long term brings significant financial savings for the company, because thanks to data analysis, it can optimize many processes and quickly reacte to events.