Looking at the several decades of WObit development, we can talk about a multi-stage evolution of the company. While the previous years were mainly related to the creation of the propulsion and measurement technology offer, the last several years have brought many key changes - you have introduced your own linear drives, stationary robots, and finally the entire range mobile robots MOBOT . Did they constitute new openings that redefined the core of WObit's activity?

Jacek Ober: All changes contribute to the evolutionary development of the company, albeit without changing its core, which are components and automation solutions. Maybe in the last decade we did not assume that we would produce our own mobile robots for the industry, but I do not rule out that the vision of WObit development at the company's founder and my father also included such a scenario. His first work was related to the construction of electronic orthopedic prostheses, as well as the creation of electronic drive systems, which was later added to measuring devices.

Przemysław Degórski: In fact the creation of linear modules and educational robots were groundbreaking moments for us. It is worth noting, however, that WObit already had its own products, although they were not cataloged - maybe except for stepper motor drivers. We treated them as complementary to motors or sensors. Later, we gathered them together under one base and decided to develop them.

The concept of creating SCARA robots was created around 2005, then the first ideas and projects related to linear modules. All our robotic activities at the time concerned mainly educational topics. We treat this period as very important for the company's development, because WObit gathered around it a large group of young people (students and other robotics enthusiasts) with whom we know each other until today and thanks to whom the company's development towards robotics has become possible. After 2010, i.e. after the death of the company's founder, we had to make decisions related to the direction of further development of WObit and we decided to build professional systems, and later also professional robotics. Despite the fact that we focused on solutions for industry, cooperation with education was still important to us, which was manifested, among others, by conducting classes in the field of mechatronics and cooperation with universities and technical schools.

Returning to robots, we were stubbornly going this way, showing in the industry that WObit is interested in a very wide range of topics related to robotics. It was also a kind of search for opportunities for us, because we did not know yet whether we would be producing SCARA robots or e.g. mobile robots. In 2014, we created the Reach for Robotics project - both to promote the company, but also to identify with a certain goal, a certain direction of our development. Robotics was becoming more and more accessible to people, and we ourselves also reached for this robotics.

|  |

What about the rest of the offer - components and small systems?

PD: With this wide offer, we could go both ways - either to develop towards typical distribution with less knowledge, or to go towards more complex products and design. Witold Ober put a strong emphasis on knowledge, on cooperation with young people, and we also chose the latter path. Looking from the perspective of what is happening on the market today, this decision was absolutely right, because customers are looking for suppliers with know-how who can both design a solution, as well as produce it and deliver it with support.

As for the distribution itself - especially of specialized products, it is still and will be an important element of our business in the future. We can say that we are currently standing on two legs - design-production and distribution. Additionally, the latter keeps us close to the news on the component market - and this has an impact on our production activities.

JO: After many talks and analyzes, we definitely decided that the key to development is to focus on added value. We offer advanced products that we have learned for many years, we also have a staff of employees with many years of experience. In addition, relationships with some of our suppliers have been going on for several dozen years and are very valuable to us. In turn, customers rarely buy single components - they look for complete solutions. We saw this when we established a research and development department more than fifteen years ago and ultimately opted for our own production of systems such as mobile robots.

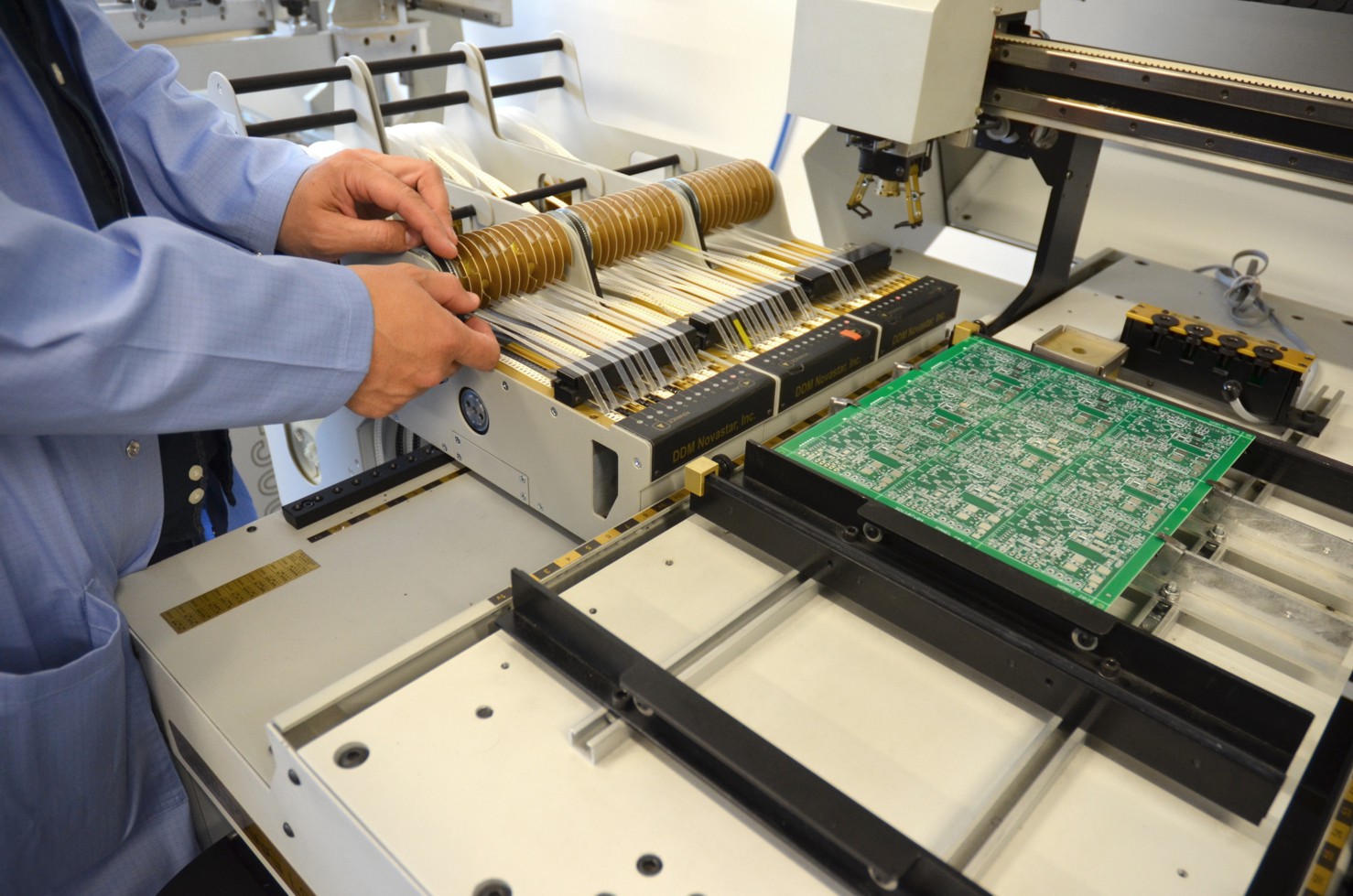

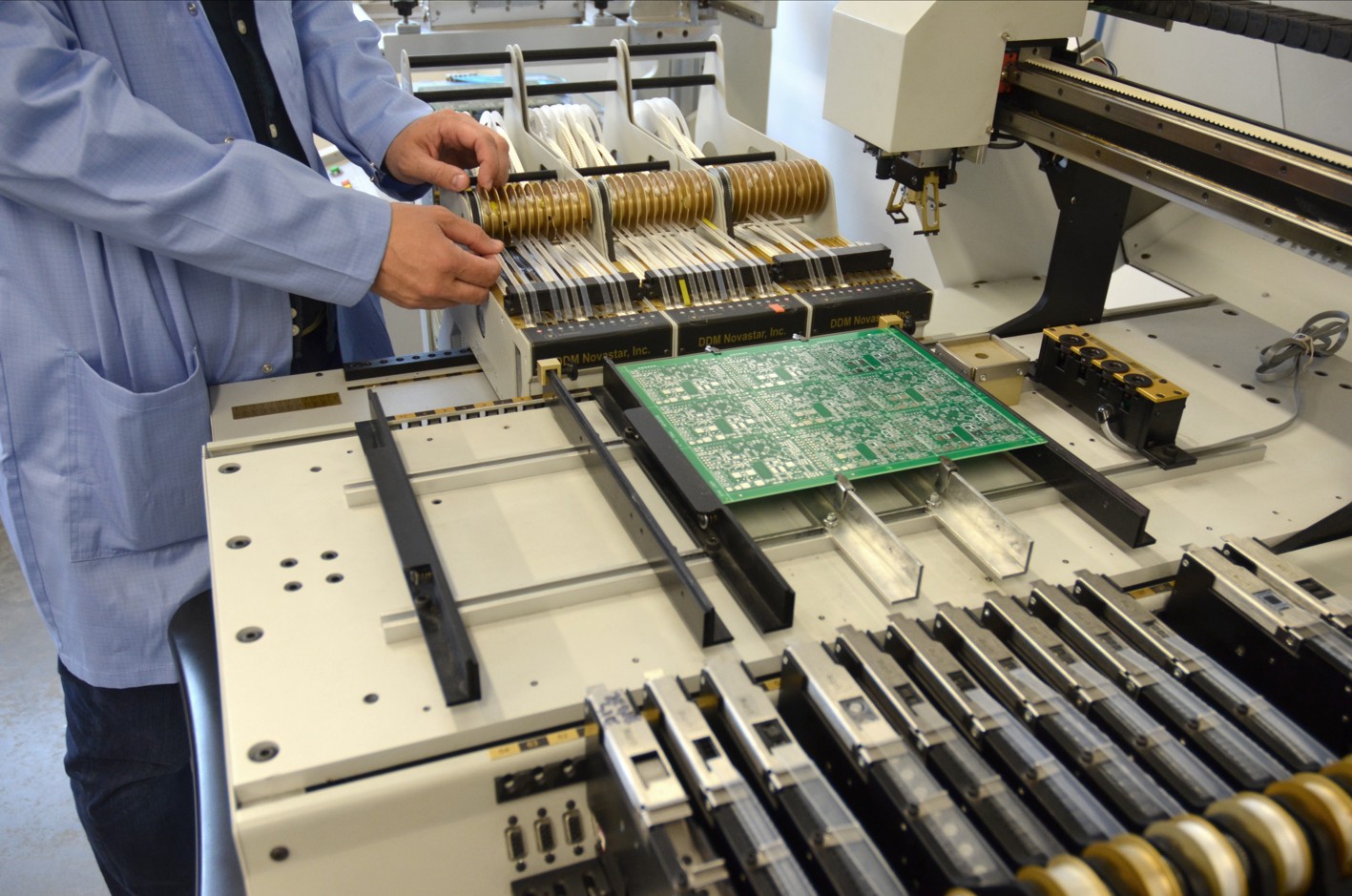

PD: I would like to add that WObit is not only complex systems such as AGV, but also our own components. If we look at the Polish market, there are many manufacturers and system integrators here, but very few manufacturers of the components themselves - in contrast to, for example, Germany or Italy. We are a company that can also produce the component that is at the base of larger systems. For two years we have been building our own magnetic encoders for which we offer several product series with different outputs. Such encoders can be made as standard products, but we also manufacture them for the needs and specifications of customers, additionally delivering them with accessories. Today, we have OEM customers for this type of products, including foreign ones.

What was the development of the offer in terms of mobile robots ? Where did the demand for AGV come from?

PD: Around 2011 we made the decision to focus on industry. At that time, we delivered small mobile robots, and there were few typical AGVs available on the Polish market, especially domestic production. We have seen such solutions in individual plants and found it would be great to locate our mobile robots in the industry as well. In addition, at that time, many young people learned mobile robotics at polytechnic universities, there were also robot competitions and other events - it created a good climate for the development of this area.

There was an idea, but also a customer who wanted to have robots transporting goods. We made a prototype for it, and then a whole series of ten mobile robots. Of course, they were very far from what we offer today - in terms of functionality, standardization of protocols, ability to perform movements, etc., although it was a significant development impulse. We later showed our robots at the fair and companies such as Toyota and Volkswagen became interested in them.

Exactly - what was the project like in Toyota plants?

PD: The project, or rather a group of projects carried out in domestic Toyota factories, turned out to be very developmental. We started out by delivering one test robot and now our machines are working in different areas. AGVs produced by WObit transport, for example, engines and hybrid transmissions. We also delivered a large robot palletizing gears to Toyota. All this works practically without the participation of employees - it is fully automated and constitutes our largest completed project. His main challenge, in retrospect, was to integrate everything into the production line, which is a living organism. It was a much more difficult and complex task than typical AGV applications, where the robot covers the route from point A to point B. I discussed the described implementation together with Mr. Krzysztof Kwaśny, Toyota General Manager, during last year's Automotive conference in Legnica.

Today, the market of mobile robots is different, many companies operate here, including foreign suppliers expanding the distribution network. Is the WObit functioning model in the form of a producer-supplier-integrator enough, or do you think about its changes?

PD: These changes are already taking place, because we are at the stage of signing a partnership agreement with one of the large companies that will use our robots in their applications. We also plan to develop the distribution market, which includes a group of system integrators. We already work with several such companies in Poland, visiting clients together with them. We are indeed changing the business model here, shifting the center of gravity towards cooperation with various partners. This change is to allow for the development of production and a move towards serial products. At the same time, we plan to maintain cooperation with our key customers, mainly from the automotive market. It is important to us, because we want to be close to technology on a daily basis, close to development and be able to observe the market needs. This approach has led us to the present, good moment in the company's history.

JO: Our participation in the Hanover fair in 2017 was an attempt to go out into the world - we wanted to see how we are perceived in an international context. At that time, our goal was to find a strong partner for whom we could produce the entire range of robots, so that they would reach the wide market through its distribution network. As we ourselves do not have such possibilities to build networks as international corporations, strategic partnership was a rational way of development. It was three years ago, but everyday life - including working with our clients - forced us to postpone these plans. Now, when it comes to building robots, software and support, we are now able to sell robots both through distribution and abroad.

|  |

As far as I know, apart from ready robots, you also offer components or systems for them - how does it look in practice?

PD: We believe that when operating on the AGV market, we should make the best products possible, but at the same time not create unnecessary restrictions for other companies that want to co-create and develop this industry. Hence, we offer them some solutions. If someone would like to use, for example, our drives or drivers, or even our navigation system, we are here to help. We want to cooperate with companies building AGV - I would like to present this statement to the market today.

JO: I think this approach comes from our long history again. My father was always open to cooperation and dialogue, not direct competition. Today we are also looking more broadly, which, moreover, is part of the blue ocean strategy - searching for new areas, not competing where there are already many suppliers. This also applies to cooperation with large companies - for example, such as Siemens and Mitsubishi, with whom we have jointly adapted our products to customer needs. We never close ourselves to such changes. Despite the fact that we offer as many as ten AGV models, we can always deliver them in a customized version - e.g. by using the solutions of the aforementioned Siemens and adjusting them in terms of components and protocols when they are delivered to a German concern. We are as flexible as possible here, because our machines are to cooperate 100% with the customer's systems.

During the coronavirus pandemic, you introduced a new mobile robot - what are its special features?

JO: I think this may be a breakthrough product for us. MOBOT TRANSPORTER , because we are talking about it, it is so different from the previous specialist products that it is a mobile robot intended for the masses. Anyway, its price is very low compared to other AGV robots and it does not require expensive implementation. We wanted to achieve the optimum between technical advancement and purchase costs and, consequently, the availability of the robot. Offering an easy-to-run robot that can be used by virtually anyone is also realizing the Reach for Robotics slogan.

PD: This is a new product that will be sold both through distribution and directly. The most important thing is that you do not need specialists to implement it, it can be done by people with basic technical knowledge. The product will be installed and run on the basis of the tutorial, along with the use of the application, e.g. on a tablet. The robot is equipped with autonomous navigation, so all programming consists in scanning the area, entering the path on which the robot is to move, and marking the action to be performed. And that's all. The robot starts!

What are the possibilities of adaptation to different applications and the use of the new robot?

PD: It allows you to transport goods in a wide variety of facilities - for example, hospitals, laboratories, public buildings, shopping malls and many others. For example, a robot can deliver goods from a warehouse to a shop hall - they are loaded and unloaded manually, while the TRANSPORTER carries out a long distance of their transport. I think that there are many similar applications on the market where the requirements are very basic and it is not necessary to use additional robot functions. Then the return on investment can be very quick. In the basic version, the robot can be easily implemented and work, for example, instead of an employee that the company lacks.

The above scenario is a baseline as MOBOT TRANSPORTER can be extended with additional elements, which allows for further automation of the process. We give the possibility to configure and adapt the robot to the needs. For this reason, we also focus on OEM companies that will use our robot to build a larger solution or system with it. We provide a universal mobile platform that can be implemented in various applications. The robot has several configurable digital I / O connectors, an expansion module and a power output. In addition, it is equipped with an Ethernet interface with the Modbus protocol, which enables data exchange with other systems. The customer can add multiple devices according to his needs and communicate them with our robot. Then, it can trigger various actions of the system, e.g. on a signal from the entrance or when the robot reaches a specific location.

To sum up - if the user does not want to use these functions, he can use the robot in the basic version. However, when it needs additional functionality - it definitely has such possibilities. I would like to add that we also provide a training service in two variants. Each user has access to online training as part of the purchase, and for companies that want to create their own systems and applications, we offer extended training at the WObit headquarters.

|  |

How does the new robot change the possibilities of your cooperation with partner companies?

Do the needs of the market not create a development impulse for other companies? There are more and more entities in the Polish AGV sector - where is the blue ocean here, and where is the competition?

PD: This market is getting dense, but there is also a lot of work to do. For example, the industry is developing towards offering autonomous vehicles that can drive not only inside buildings, but also outside. I have the feeling that we create this market to a large extent. So although the aforementioned competition is developing, the industry itself is growing, which creates new business prospects for suppliers.

JO: The discussed processes were undoubtedly given dynamics by the coronavirus itself. Due to the pandemic and problems in many areas of the economy, people have turned to automation. It can be assumed that otherwise this process would take much longer, as the demand would grow more slowly. I believe that the WObit company has responded perfectly with its new offer to the needs of the currently changed market.

Finally, let's come back to education, which, after all, is one of the key areas of the company's operations. Is it possible to understand that despite your focus on business, you are not dissociating yourself from the educational topic?

JO: Definitely! We constantly conduct a series of trainings at the Poznań University of Technology and other universities, we also co-create a mechatronics technical college in Pniewy, where our employees conduct lessons and workshops. We provide local youth with opportunities to develop in this area. In addition, we constantly offer Explorer , which are intended, among others. for schools. They give you the full opportunity to learn and experiment with mobile platforms.

As a company, we are also present at several technical universities in Poland, providing substantive and product support for various scientific circles. These are teams of students - disciplined, young people who, with incredible commitment, determination and passion in creating more and more advanced projects, achieve international success, and in Poland as future engineers they create their own reality, at the same time contributing to the development of, for example, the space sector.

Due to the aforementioned resource constraints, we had to reduce our commitment to education, but as you can see, we did so with great regret. However, in the field of mobile robotics, we plan to come back soon, but with a more professional product. We also want to educate older teenagers in the field of industry - an area that they will have to deal with right after graduation.

What are the directions of the future development of the company?

JO: We talked earlier about the expansion and development of the distribution network - we also planned it for this year from the foreign perspective. We had as many as five foreign events planned for 2020, including: Logimat, Automatica and Hannover Messe. For obvious reasons, we only managed to do one thing, at the very beginning of the year in Abu Dhabi. We presented our smallest MOBOT eRunner MW in the Innovation Room during the X World Urban Forum - an educational, business and image-related event. I hope that we will enter a new market this year, but it is too early to talk about it. However, the direction of development has been maintained - it is the next, evolutionary stage of the company's development, while still based on what WObit itself is. Since 2012, we have been promoting the slogan "components and solutions for automation" and today, I think, we go out with it even more - we reach not only to automation and industry, but also to other sectors of the economy.

Thank you for the interview.

Zbigniew Piątek

source: www.automatykab2b.pl