When we require precision, stability and reliable measurements, it is worth checking out the highest quality devices offered by the German company Micro-Epsilon. This time, we will focus on two measurement techniques, excellent depending on external conditions.

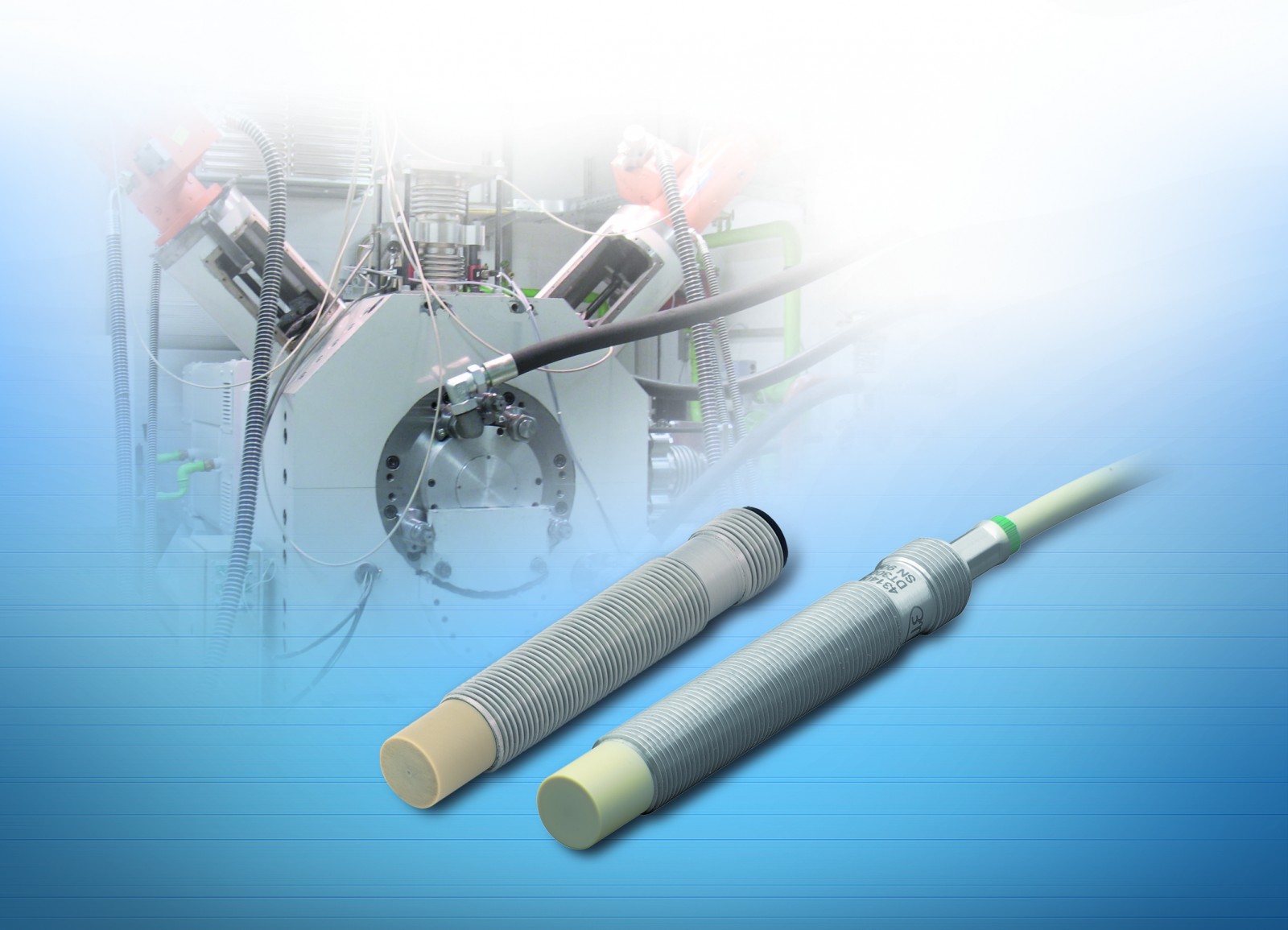

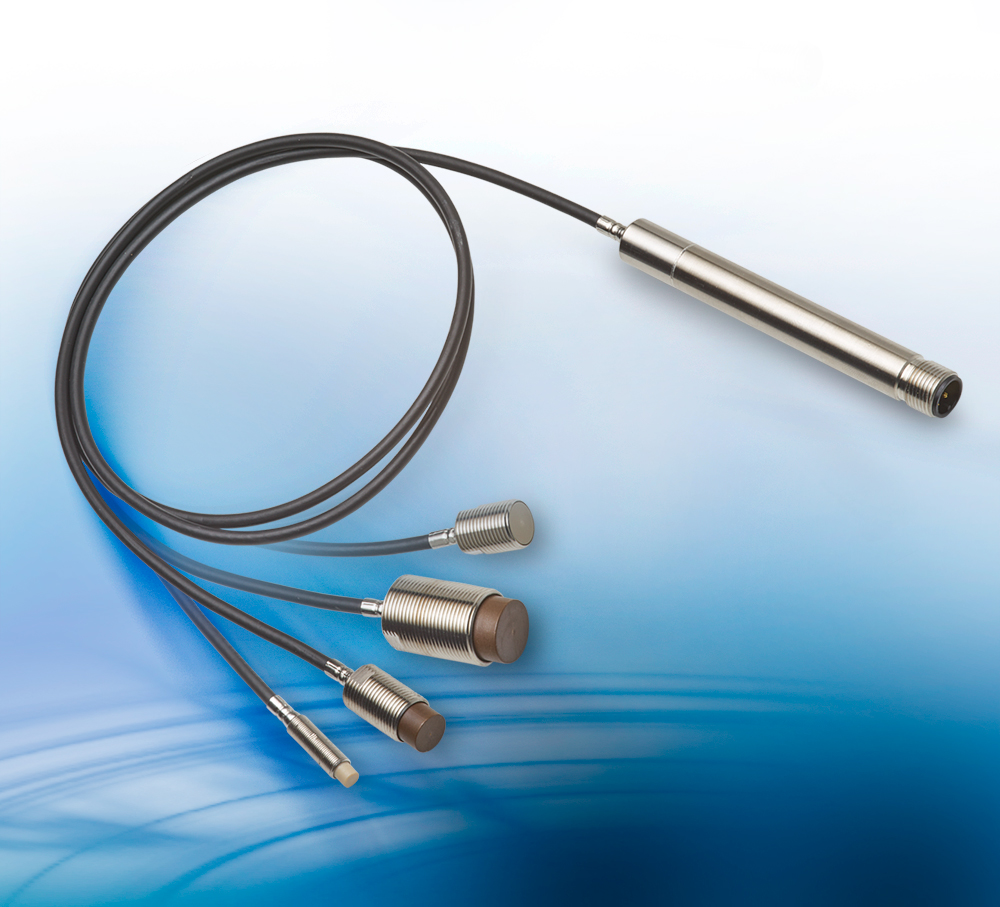

Measurement in a highly dusty, dirty environment

When we are dealing with a heavily polluted environment, exposure to oil, dirt, dust, humidity, electromagnetic field or high pressure, it is worth using a href="https://wobit.com.pl/produkty/980/czujniki -wiropradowe / "target =" _ blank "> vortex sensors resistant to these factors. They work well in the most demanding applications, which are fast industrial processes.

The sensors are designed for measurements with respect to metal elements. Due to the non-contact measuring principle, they do not wear out mechanically. Measured objects can have ferromagnetic and non-ferromagnetic properties.

In addition to the obvious advantages of Rotary sensors , there are also disadvantages that can be considered calibration and linearization requirement during sensor replacement. In addition, the measurement is limited to metal elements.

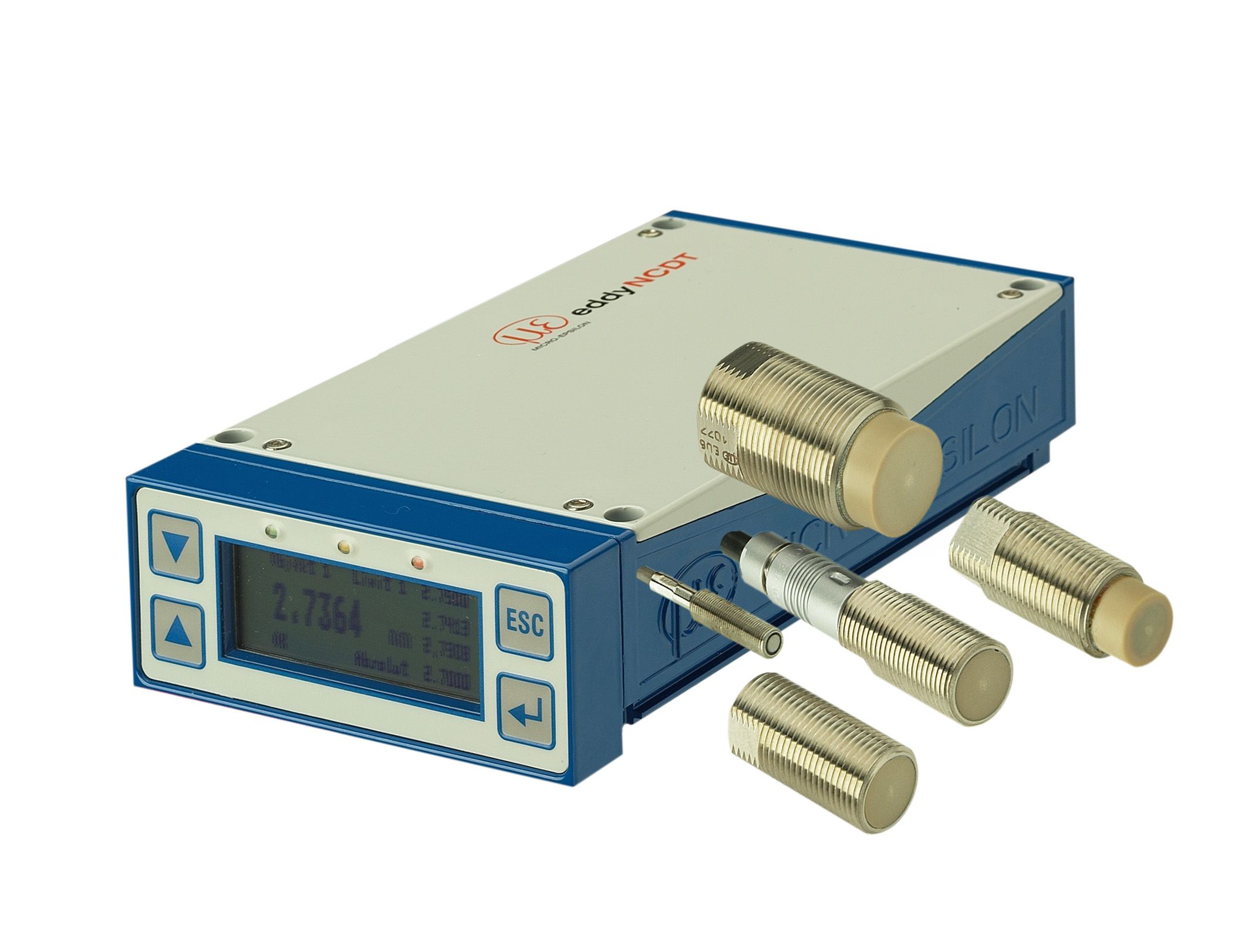

Work in a clean environment / Clean room

When these factors matter, and the work environment is clean Micro-Epsilon proposes capacity sensors which are used to measure electrically conductive components, also non-metallic. Unlike vortex sensors, they do not require calibration, and the partially modular construction of the measurement system makes replacing the sensor take several dozen seconds. We also guarantee a very stable measurement result.

| Micro-Epsilon in its capacitive sensors uses the capacitor plate perfectly. The sensor consists of a shielding ring, electrode and earthing, placed on the edge of the sensor together with the measuring electrode. Double shielding guarantees a high quality measuring signal. To enable simultaneous use of eight measurement channels depending on the requirements, capaNCDT systems are designed as modular systems. They are additionally equipped with a linearization function, which makes it possible to measure against insulating materials. |

Due to the very high accuracy of the measurement (resolution up to 0.0375 nm), capacitive sensors Micro-Epsilon are used wherever very precise positioning is needed, e.g. for lens adjustment in measuring machines, telescopes, etc. In the semi-conductor industry, displacement sensors are used to adjust the lenses during exposure PCB board.

Another area used is the automotive industry, where they are used, among others for measuring the deformation of the friction ring on the brake disc. This measurement is difficult to implement due to the red, high temperature metal (up to 1000 ° C), requiring high resolution.

The above-mentioned measurement methods are suitable for applications where the measuring range is limited to several tens of millimeters. However, when there is a need for measurements within the range of several hundred millimeters, it is usual to use optical sensors .