Effective management of production processes requires the use of functional and at the same time convenient methods.

HMI panels as its name suggests, it is a comfortable, graphical interface for communicating people with machines, while system SCADA enables quick factual inspection of machines and devices, and also provides transparent graphical information, including about alarms and supports the operator and managers in their work.

The company WObit for the management and visualization of individual processes is proposed by several series operator panels from Kinco. Among them, the most popular successfully without any doubt is economic and functional series MT4000 . It is characterized by a number of communication protocols (eg Modbus-RTU) with built-in serial ports, including USB, allowing programming the panel from a PC. |  |

Thanks to the clear display and fast working colors provided by the 32-bit processor, MT4000 series is the right solution for most applications in the field of industrial automation. More advanced and giving more application possibilities is MT5000 series . The devices are equipped with Profibus-DP, CANopen, Ethernet and MPI network interfaces with the support of MPI compatible network configuration. Thanks to their functionality, these panels can be used in a variety of applications, even those that require resistance to external factors such as temperature and humidity.

As mentioned in the introduction, visualization and control of a single process as possible by the HMI panel, it is worth connecting to a larger system managed by SCADA software, which will enable collecting and saving a large amount of data from several positions. This will allow a more efficient analysis of processes.

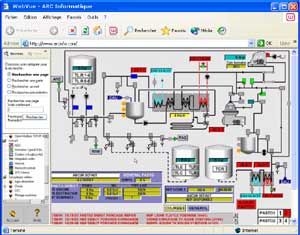

| WObit proposes a SCADA PcVue system, which the latest version 11.2 is equipped with three tools that allow you to shorten the time of application configuration: Application Architect for creating templates, Application Explorer, which supports diagnostic operations by displaying the data flow within the PcVue , as well as between SCADA and external components, as well as Smart Generator for importing data from external sources. This allows you to automatically generate applications, synchronize configuration data and eliminate errors in a single step. PcVue 11.2 has a user-friendly environment, a set of built-in animations, object libraries, which enables quick and easy development of the project through on-line configuration. The software supports features such as animated 3D objects or built-in GEO Maps, ensuring more efficient operator work. |

PcVue supports a very wide range of communication standards, including built-in controllers for the industry and machine manufacturers (about 200 new and older protocols), building management systems (LNS, BACnet, SNMP), power generation, T & D and energy systems (IECS, DNP3 ), water purification and distribution systems.

SCADA PcVue has inbuilt internal message mechanisms, also provides redundancy for key applications that can easily be configured using the network wizard. The software is available with the TouchView add-on, which enables you to use mobile devices: thanks to which it is possible to access data from a smartphone or tablet (only with Windows). It is also possible to configure in online mode, thanks to which you can change the parameters without interrupting the system.