Precision is crucial in the treatment of components. This parameter is extremely important also in welding applications, automated painting or in the positioning of large masses. The solution that ensures the transfer of traffic from the drive unit to the target object with the utmost precision is the cycloidal transmission. WObit offers excellent Nabtesco reducers .

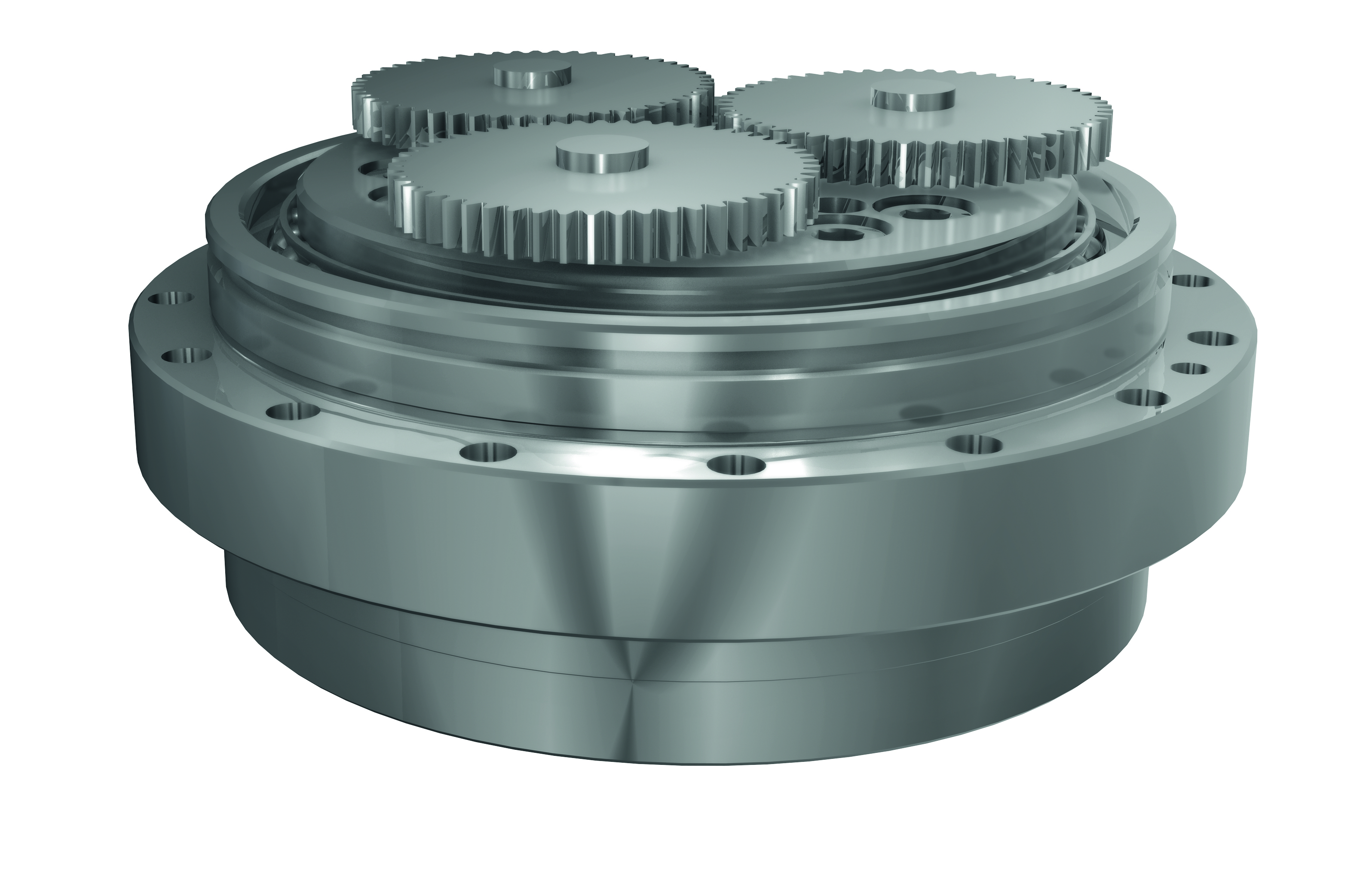

Cycloidal gearboxes allow you to get a very high torque on the output shaft, exceeding up to 78 000 Nm temporarily, and the availability of large diameters allows optimal use of the drive unit. These elements are characterized by compact construction, high stiffness and very low clearance, much below one square minute.

The cycloidal gearbox usually has only two degrees of depth, which is why its dimensions and weight are much smaller than the corresponding planetary gears. Small gaps also allow for the implementation of very precise traffic. Despite the very large forces on the output axis, the Nabtesco gearbox can work with amazing dynamics and precision.

Depending on the type of application, Nabtesco gearboxes are available in a ready-to-assemble version (RD2 series), as well as the version without housing and seals to be integrated, eg in a robot arm (RV series). Both RD2 series and RV series are available in a version with a hole that makes it easier to route cables through a transmission, for example. The reducers are available with an input located parallel or perpendicular to the axis of rotation of the output flange. The presented reducers enable a very high output torque, rated above 6800 Nm. | .jpg) |

Gearboxes for CNC machining centers

In the case of workpiece machining, the tools must be positioned at high speed with precision in the micrometer. The implementation of the full process together with the simultaneous holding of the element prevents inaccuracies caused by frequent overloading of the workpiece. Compact, precise gearboxes with a full transverse spectrum ensure accurate positioning of the linear disk tool magazine. Nabtesco has prepared a series of RA for drives in such magazines in the machining industry. A properly selected reducer allows elimination of repeatable inaccuracies and their increase due to the continuous rotation of the linear tool magazine in the same direction, and also provides absolute positioning precision at any time.

Gearboxes for painting robots

Gearboxes for positioners

Robotic welding lines of the latest generation work quickly and with absolute precision. To ensure the perfect arrangement of the detail, positioners and rotary tables are used. The gearbox provides the drive for each rotary axis of the welding tables. In this way, all welding points in one axis, even with a complex geometry, can be welded together with high precision without the need to translate the part. In this process, the weld pool must be kept exactly in the bowl. This is only possible when the transmission operates with absolute precision and repeatability. It follows that even the smallest deviations cause incorrect welding.

Strong and super-precise Nabtesco series RV-C , RV-E and RD-C are ideal for welding applications. They are compact and distinguish themselves with a high resistance to dynamic loads (up to five times greater than the rated torque). Additionally, in the translations RV-C and RD-C wires and power lines can be routed through the hole. RD reducers have a closed and sealed housing, filled with grease and are ready to be mounted on the servo motor. They are characterized by high torque, high rigidity and very high precision (clearance less than 1 arc minute). |  |

Solution for mobile robots

Recently a new series of RF-P transmissions, characterized by a very compact design and high output speed has been added to the WObit offer. This series is ideally suited to use, among others in mobile robots. The WObit company, which is a producer of AGV robots , proposes complete drive system dedicated to these devices.

It consists of efficient brushless BG95x80 engine with integrated Cycloidal converter RF-19P and controller mcDSA-E25. The transmission has a 31: 1 ratio as standard, allowing torque output of 90 Nm at a speed of 113 rpm. Directly on the gearbox, you can attach a robot wheel, which should have a minimum diameter of 280 mm, which will allow you to obtain a linear speed of up to 6 km / h. More information about the applications and details of Nabtesco gearboxes can be found at www.wobit.com.pl .