Most electronic components are surface mounted, but many specialized components still require through-hole assembly, which can be done manually or automatically. For the automatic implementation of this process, WObit proposes the use of Desktop robot of own production, equipped with appropriate accessories.

Thanks to its implementation, you can significantly increase production efficiency, ensure repeatability, and improve the quality of solder pads. The basis of the CDR480 robot is the Cartesian desktop platform, which allows the displacement to be carried out in four axes, of which three axes perform linear motion and one rotational movement.

The device has a large working range, which for the X and Y axes is 450 mm, for the Z axis 100 mm, and for the rotary axis (R) 340 °. The maximum speed in the X and Y axes is 200 mm / s, in the Z axis 100 mm / s, and in the rotary axis 340 ° / s, which allows for dynamic implementation of processes. The desktop robot is characterized by a high positioning resolution up to 0.006 mm in the X and Y axes, 0.003 mm in the Z axis and up to 0.1 ° in the rotary axis. Repeatability in linear axes is 0.01 mm, while in the R axis is 0.2 °. The robot can be loaded with a mass of up to 10 kg.

A specially designed controller watches over the work of the robot. It allows to generate a trajectory of movement of all axes of the device and control of other functions of the implemented process. The programming of the robot is carried out via a PC computer, while the work program can be selected on 4.3 & # 8221; display, or externally via the RS485 bus.

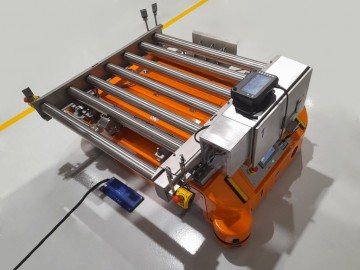

The desktop robot is adapted to cooperation with dedicated transporter . It allows the implementation of an automated process. On transport system consists of the main assembly module on the robot mobile table and side modules, feeding and receiving element. |  |

Robot can be adapted for soldering through-hole elements, by retrofitting it with specialist accessories. A head with an integrated tip holder and an adjustable supply tube for the soldering wire can be mounted on the robot's vertical axis. The head should be adapted to efficient continuous operation.

CDR480Â can also be equipped with a wire feeder Tin, adapted to co-operate with the installed head To provide a high quality of solder points in the niche, the soldering wire can be cut at regular intervals during administration.

In order to ensure the efficiency of the soldering process, the robot can be equipped with a rotating soldering tip cleaning station in which automatic cleaning cycles can be programmed. This station is equipped with brushes that allow the removal of accumulated debris.

Robot control is carried out with a dedicated controller that allows, among others, generating the trajectory of the robot's movement and precise programming of the soldering process. The process includes parameters such as: heating temperature, soldering time, quantity and speed of the wire being fed.

Necessary equipment robot for such an application is also a mainsail temperature controller that will allow you to dynamically react to changes taking place and maintain a constant temperature value. It is also possible to program the resting temperature of the tip, which will extend its life.

More information about robots and applications can be found at www.wobit.com.pl and by calling 61 22 27 422.