New technologies and advanced production techniques constantly contribute to the modernization of food and beverage production. In this article, we will analyze some of the latest developments in the beverage industry and explain how they are helping to improve quality and reduce environmental impact.

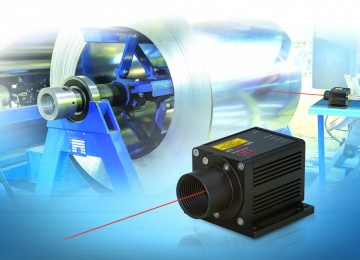

In the production of glass bottles, wall thickness and product roundness are key quality characteristics. Therefore, these parameters must be checked 100%. During inspection, any defective containers are immediately rejected and returned for re-melting and further production. Due to the high processing speeds and to prevent bottle damage, a fast, non-contact measurement procedure is required. Two-channel confocal measurement system with the designation confocalDT 2422 combined with Micro-Epsilon's IFS2406-10 sensor is ideal for this task. It enables non-contact measurements of distance and thickness of transparent materials with simultaneous synchronous measurement at two points. The controller provides versatile interfaces, including EtherCAT and RS422, which are designed for real-time data transfer. The sensors have a large measuring range of 10mm with a sensor diameter of 27mm. The thickness calibration function allows for precise measurements of bottle wall thickness over the entire measuring range of the sensor. Automatic exposure control enables stable measurements regardless of the glass color. Thanks to this, an effective production process is controlled, eliminating any defects in the molds used to create the appropriate shape of the bottle. You can then maintain the appropriate level of material consumption and thus better plan the entire production process, from the purchase of raw materials to determining the quantity of the final product. This is also of great importance nowadays, where great emphasis is placed on the aspects of sustainable use of natural resources.

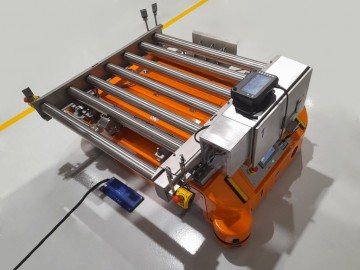

The second example from the food and beverage production industry is the use ofprofilometers laserfrom Micro-Epsilon. In this application, they are used for quick and fully automatic inspection of empty containers in bottling plants and breweries. For this application, the integrator used precision devices from Micro-Epsilon and designed a test system based on laser line triangulation, used when receiving bottle crates. This embedded system is equipped with five scanCONTROL 2900-50 laser profilometers from Micro-Epsilon. Boxes transported on a belt are scanned from the top. Each profilometer measures a row of bottles in crates. The presence of objects is monitored at a conveyor speed of up to 850 mm/s. A profilometer measures the appropriate height of the bottle to determine whether the correct type of components are in the crate. The height of glass containers must not deviate by more than 3 mm from the target height of the corresponding bottle type.

Compared to a solution based on conventional image processing systems, laser profilometers not only monitor the presence of bottles, but also their height. In addition, recorded data can be collected for further statistics, evaluations and process optimization. The measured values are evaluated directly during the production process. Via GigE Vision, raw data is integrated with imaging software and then evaluated. The PLC receives the evaluation result as an "OK" or "Not OK" value, so any defective boxes can be removed directly. The user can also view measurement results via the integrated display on the control unit.

The challenges of this measurement task lie primarily in the different reflective properties of the bottles. They differ due to the colors of the glass (mainly shades of green and brown), as well as the fact that the containers are delivered with or without a cap. Additionally, bottles constantly vibrate and shake while being transported on the conveyor belt, which can make measurement difficult. Micro-Epsilon laser profilometers overcome these challenges and consistently deliver accurate measurement results.

Using advanced technology implemented in the latest devices and combining it with our own experience and knowledge, we can create an effective system supporting food production. It is more aware from the point of view of the Quality and Production Departments. By checking measurement points, you can easily analyze and control production at every stage, eliminating any errors.

Will this solution work for you? Want to learn more about transport automation or measurement? Contact WObit specialists.