Increasingly, in industrial processes, accurate devices for the control of dimensions, surfaces, and thicknesses, such as profile laser scanners, are used. The German manufacturer of these devices expanded its offer, opening up new measurement possibilities.

Principle of operation and selection of the appropriate laser diode

Laser profile scanners are non-contact measuring techniques, characterized by a long service life due to the absence of wear parts. Their operation is based on the principle of laser triangulation for two-dimensional determination of the surface profile of various objects.

Unlike point sensors, laser line sensors use a static laser line that they project onto the surface of the measured object. The high-quality optics project the scattered light of this laser line onto a highly sensitive sensor array, which detects a profile with 640, 1028, or 2048 measuring points in one measurement, depending on the sensor type.

Based on the matrix image, an integrated controller calculates the distance information (Z-axis) and position along the laser line (X-axis) in a two-dimensional coordinate system. In the case of adding movement in the (Y) axis directly above the measured object, it is possible to obtain information from all planes and finally obtain a three-dimensional image.

Micro-Epsilon laser scanners are available with a red and blue laser diode configuration. For popular tasks, a red laser diode with a wavelength of 658 nm is sufficient. However, when measuring on red-hot metals, as well as on transparent and organic surfaces, the patented blue laser with a wavelength of 405 nm will work best. It provides better stability because the shorter-wave blue laser beam does not penetrate the measured object. The scanner displays the laser line on the measuring surface, allowing you to obtain a perfect profile and precise results.

COMPACT and SMART versions

Scanners in the COMPACT version allow access to the raw point cloud and the creation of proprietary software made by the client. Micro-Epsilon offers access to libraries in C, C ++, and VisualBasic. Installers for LabVIEW and a Linux implementation are also available. Operating under the international GigE Vision standard, COMPACT sensors can also be integrated into industrial image processing systems.

Settings and configuration of profile parameters using scanners in the SMART version are performed using the scanCONTROL Configuration Tools software. The key feature of the scanner in the SMART version is the ability to save the configurable geometric values and the settings in the controller integrated inside the scanner. As a result, the obtained values are sent directly from the scanner via MODBUS TCP or optionally via PROFINET, EtherCAT, or EtherNET / IP.

New scanCONTROL 2500 series

A low-cost series of scanners of the scanCONTROL 2500 profile has been prepared for serial applications. It is available in two standard variants for all scanners, ie. COMPACT and SMART. The LLT2500 series profile scanners in the SMART version allow the configuration of 4 measurement programs available in the scanCONTROL Configuration Tools software while providing 4 measurement results per profile. This ensures reliable measurement of angles, degrees, gaps, and other parameters.

Depending on the application, it is possible to modify the sensors by using protective housings, different types of cables, or by operating with an interface converter.

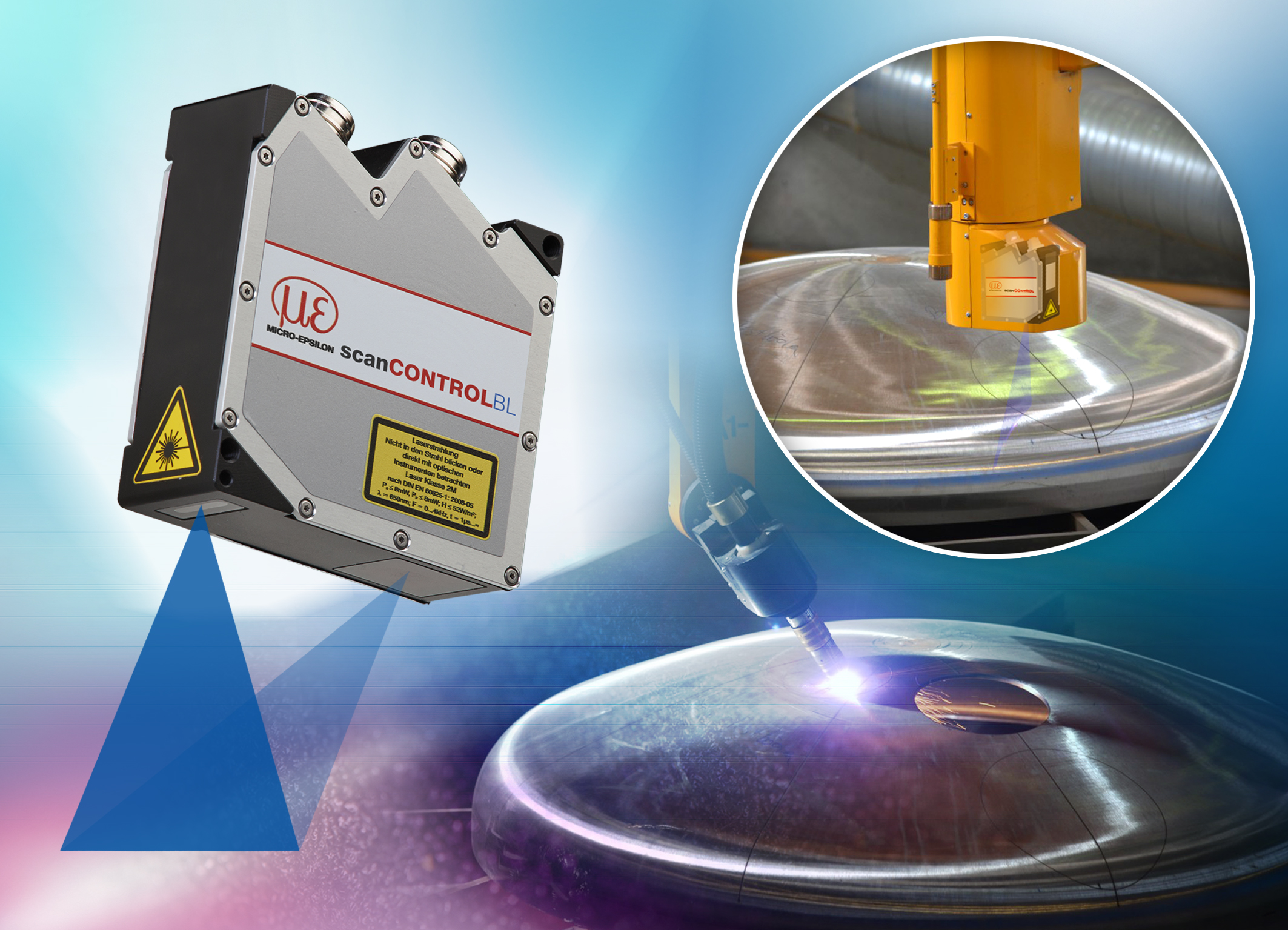

ScanCONTROL 2900 series - An example of implementation in automated plasma cutting

To process huge workpieces with automated plasma cutting systems down to a micrometer, reliable 3D measurements of the workpieces must be made in advance. Slovak company MicroStep, spol. S r.o. is a specialist in CNC cutting machines. MicroStep has developed a special machine that performs automatic cutting operations, primarily on dome and boiler covers. The machine processes domes up to 7 m in diameter and up to 1.2 m high. During an automated process, holes for tubes and valves are cut in the huge domes.

To perform the cutting process with the highest precision, the manufacturer uses the Micro-Epsilon scanCONTROL 2900 laser scanners. They determine the geometric dimensions of the element and the exact position of the dome in the place of the working area of the plasma head.

The use of Micro-Epsilon laser profile scanners in this application has many advantages. Thanks to its compact design and high speed, ie. up to 60 m / min, it is ideal for integration on this type of production line. The measurement values of the high-performance sensor can also be used to check the quality of the cuts being made. ScanCONTROL 2900 provides a density of individual measuring points of 80 µm for a range of 100 mm. High accuracy is also maintained for demanding metal surfaces with varying reflectivity.

The laser profile scanner also offers high repeatability of up to 50 µm / m. This ensures a consistently high quality of the plasma cutting process performed. Determining the measured values with high-precision laser scanners is necessary because the actual dimensions of domes often differ by several centimeters from the CAD data. The information obtained from the scanners is then compared with the actual dome position data to ensure the correct positioning of the cutting tool. Synchronization of 2D line information with the 6D scanner positioning system provides the user with a full three-dimensional form and true shape of the part. Via SDK libraries, they are sent as a point cloud to the client's mSCAN software, which detects the exact center of the dome, in order to establish the optimal tool trajectory.

Scanners for special tasks – scanCONTROL 30xx series with blue laser

The most dynamic applications require special solutions for which the scanCONTROL 30xx series with a blue laser line has been prepared. The new scanCONTROL 30xx blue laser scanners are available with measuring ranges of 25 and 50 mm (along with the laser line / X-axis). They ensure obtaining geometric values of a 2D profile with an efficiency of about 5.5 million points per second and generate up to 2048 measurement points per profile on their profile line. The scanCONTROL 3060-25 / BL models achieve a resolution in the X-axis of approximately 12 µm. From September, scanners with a measuring range up to 200 mm are also available.

Due to profile frequencies up to 10 kHz, the new profile laser scanners are designed for high-speed production processes.

Thanks to the innovative High Dynamic Range mode, the sensor generates precise measurement results even on uneven surfaces. The output of the determined values is sent via Ethernet or RS422. Also, the optional scanCONTROL Gateway II solution enables the integration of these intelligent sensors into control systems over Profinet, EtherCAT, or EtherNET / IP. Devices prove themselves wherever they are crucial benefits of a blue laser, presented in detail at the beginning of this article.

Are you interested in the article? You need to get detailed information about individual models - contact our advisors who will choose the right scanner for your needs.

Source: https://www.micro-epsilon.com/press/release/PR459_Plasmaschneiden-Dome/

See our products

ScanCONTROL 2950-100 / BL laser scanner

ScanCONTROL 2950-100 / BL laser scanner ScanCONTROL 2510-50 laser scanner

ScanCONTROL 2510-50 laser scanner ScanCONTROL 2500-50 laser scanner

ScanCONTROL 2500-50 laser scanner ScanCONTROL 3050-25 laser scanner

ScanCONTROL 3050-25 laser scanner ScanCONTROL 2910-25 laser scanner

ScanCONTROL 2910-25 laser scanner ScanCONTROL 2900-25 / BL laser scanner

ScanCONTROL 2900-25 / BL laser scanner ScanCONTROL 2910-100 laser scanner

ScanCONTROL 2910-100 laser scanner ScanCONTROL 2950-25 laser scanner

ScanCONTROL 2950-25 laser scanner Configuration tools

Configuration tools ScanCONTROL 3010-200 laser scanner

ScanCONTROL 3010-200 laser scanner ScanCONTROL 2900-50 laser scanner

ScanCONTROL 2900-50 laser scanner ScanControl 3050-50 laser scanner

ScanControl 3050-50 laser scanner ScanCONTROL 2500-100 laser scanner

ScanCONTROL 2500-100 laser scanner ScanCONTROL 2950-100 laser scanner

ScanCONTROL 2950-100 laser scanner ScanCONTROL 2510-25 laser scanner

ScanCONTROL 2510-25 laser scanner ScanCONTROL 2500-25 laser scanner

ScanCONTROL 2500-25 laser scanner ScanCONTROL 2900-25 laser scanner

ScanCONTROL 2900-25 laser scanner ScanCONTROL 2900-10 / BL laser scanner

ScanCONTROL 2900-10 / BL laser scanner ScanCONTROL 2910-50 / BL laser scanner

ScanCONTROL 2910-50 / BL laser scanner ScanCONTROL 2950-25 / BL laser scanner

ScanCONTROL 2950-25 / BL laser scanner ScanControl 3050-200 laser scanner

ScanControl 3050-200 laser scanner ScanCONTROL 2910-10 / BL laser scanner

ScanCONTROL 2910-10 / BL laser scanner scanCONTROL BL

scanCONTROL BL ScanCONTROL 3010-25 laser scanner

ScanCONTROL 3010-25 laser scanner ScanCONTROL 2510-100 laser scanner

ScanCONTROL 2510-100 laser scanner ScanCONTROL 2950-10 / BL laser scanner

ScanCONTROL 2950-10 / BL laser scanner ScanCONTROL 2910-100 / BL laser scanner

ScanCONTROL 2910-100 / BL laser scanner ScanCONTROL 2900-100 / BL laser scanner

ScanCONTROL 2900-100 / BL laser scanner ScanCONTROL 2910-25 / BL laser scanner

ScanCONTROL 2910-25 / BL laser scanner ScanCONTROL 2910-50 laser scanner

ScanCONTROL 2910-50 laser scanner ScanCONTROL 2950-50 / BL laser scanner

ScanCONTROL 2950-50 / BL laser scanner Skaner laserowy scanCONTROL 3000-200

Skaner laserowy scanCONTROL 3000-200 ScanCONTROL 2900-50 / BL laser scanner

ScanCONTROL 2900-50 / BL laser scanner ScanCONTROL 2950-50 laser scanner

ScanCONTROL 2950-50 laser scanner ScanCONTROL 3000-25 laser scanner

ScanCONTROL 3000-25 laser scanner Skaner laserowy scanCONTROL 3010-50

Skaner laserowy scanCONTROL 3010-50 ScanCONTROL 2900-100 laser scanner

ScanCONTROL 2900-100 laser scanner ScanCONTROL 3000-50 laser scanner

ScanCONTROL 3000-50 laser scanner

.jpg)