The cosmetics industry offers hundreds of products that promise a great look. Striving for perfection and high quality is manifested not only in the creation of products, but also their packaging. What's more, very precise solutions are present in the manufacturing process to enable you to maintain quality > at a constant, high level. One such tool are color sensors from Micro-Epsilon, an innovative manufacturer of high-end measuring devices with over 50 years of experience.

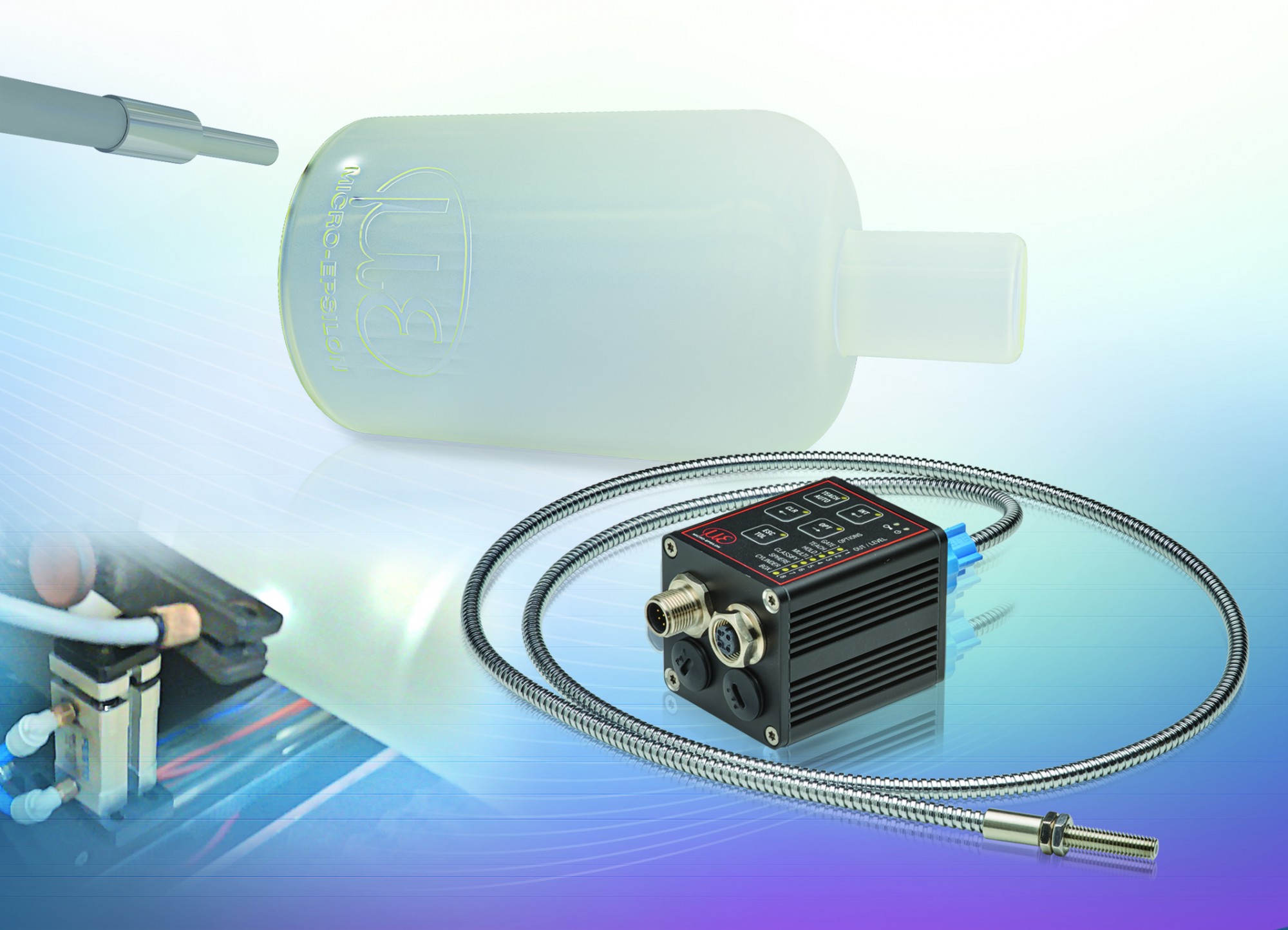

One example of the use of these devices is the use of the ColorSENSOR CFO100 for precise position detection in automated cosmetics bottle printing processes. Translucent glass-ceramic bottles are embossed before printing. There is a minimal color difference due to the indentation at the embossing point. The Micro-Epsilon ColorSENSOR detects this deviation and therefore determines the exact location of the printout.

Color sensors > Micro-Epsilon are not just for precise color measurement. They can also be used to perform tasks related to detection, testing or positioning. David Blankenaufulland uses these Micro-Epsilon color sensors. The company develops and manufactures CNC screen printing machines for printing on various containers made of plastic, textiles, ceramics or glass.

When automatically printing on translucent glass-ceramic bottles, it is necessary to specify the exact printing position. That is why the reference mark is embossed on the bottles. Due to the indentation, the color of the reference mark slightly differs from the rest of the bottle surface. ColorSENSOR CFO100 detects this minimal color difference, which allows you to specify the exact printing position below the embossing.

ColorSENSOR shows a clear advantage over other measuring methods. First, it controls the translucent surface. Secondly, it is ideal for this kind of position measurement tasks due to its favorable price-performance ratio. For this measuring task, colorSENSOR CFO100 is integrated into the device , which is the optimal solution for an efficient printing process.

Thanks to the high measurement frequency it sends a full OK / NOK signal in a specified cycle time of less than two seconds. The small size of the measuring spot with a diameter of just 0.6 mm ensures reliable and precise detection of embossing. Due to the spatial separation of the measuring point and signal processing, the sensor is resistant to typical ambient conditions, such as dirt and temperature inside the machine. The compact and robust controller can be easily and quickly integrated into the back of the machine, and the space-saving fiber optic with the sleeve can be placed at the measuring point.

Is ensuring high quality also relevant in your industry? We invite you to familiarize yourself with various measuring techniques that will help you achieve this. Our specialist will help you choose the right one, and you can contact here .