There are many models available on the market current motors permanent and servo drives , as well as gearboxes. This large selection is on the one hand easier, on the other a multitude of options can give the constructor a headache associated with the selection of the optimal solution.

Here, two intuitive tools created by Neugart, of which WObit is a representative in Poland, come to the rescue. They allow you to quickly and easily choose the right gearbox.

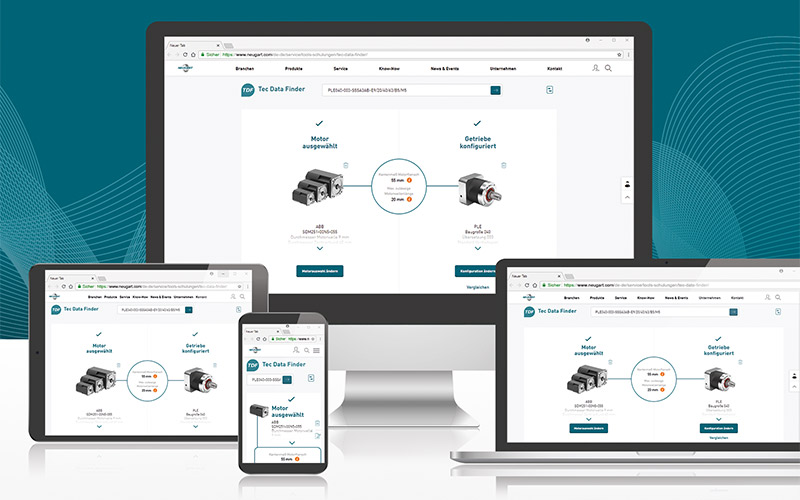

The first tool is Tec Data Finder (TDF), which allows you to generate a data sheet with a technical drawing of the planetary gear, matched to the dimensions of the engine. Data is provided in the form of CAD models to reduce design time. TDF from Neugart can also be used on mobile devices. Easy-to-use interface, automatically adapts to mobile devices thanks to its responsive design. |  |

Another advantage of the new version is the flexible start of configuration. The user can decide whether to start the configuration with the engine or transmission. TDF checks the geometrical compatibility of the gearbox and engine. The choice of engine or gear configuration is limited depending on the initial variant. This means that only gearboxes that can be attached to a given motor are displayed, or only motors that can be connected to a specific gearbox.

New users can also benefit from illustrated explanations during gear configuration, which allows quick and easy selection.

The database has over 17,000 engines of all the most popular drive manufacturers to choose from. If the engine is missing, the user can enter the dimensions of the model it has. Entering is supported by interactive fields in which the required engine values are marked in color in the technical drawing. Engine data can also be entered in metric or imperial units, i.e. in the Anglo-American measurement system.

Another advantage is the ability to compare up to five gears. Differences in technical data are marked in color with one click. You can immediately see which gearbox optimally meets the technical requirements.

CAD models, technical data can be ordered after configuration with a request for a quote. Registered users also have access to previous configurations via the user account. This facilitates the reuse of CAD models, technical data sheets and RFQs.

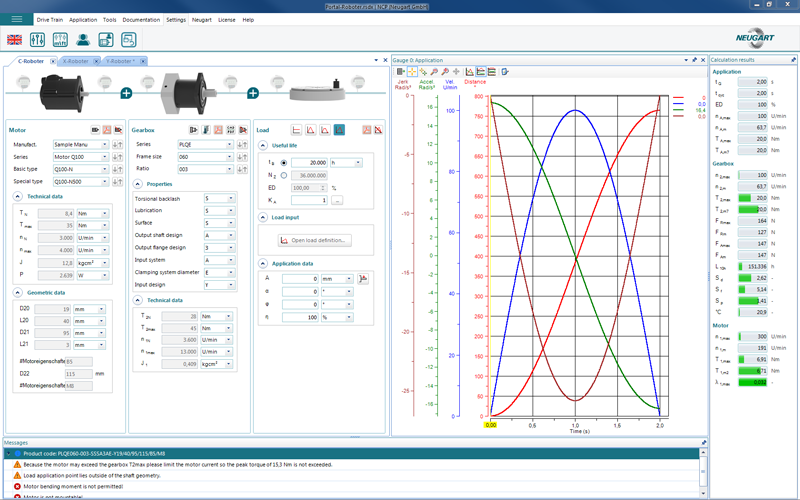

TDF is compatible with the second tool, calculation program (NCP) for dimensioning and checking application related parameters. After configuring the transmission / engine combination in TDF, you can download the NCP control system file. The file can then be imported into NCP. The configured transmission / engine combination is automatically created in the NCP, and all the user needs to do is enter the application data to calculate the entire drive system. |  |

In just a few minutes it is possible to configure the right combination of engine and transmission based on the entered application data. It thus becomes cost and energy efficient for the user.

In the background, the complex program procedure calculates all parameters for the entire propulsion system. Despite this complex process, the tool is easy to use: the NCP user interface has a clear, intuitive structure.

All parameters are visualized in real time and you can easily compare similar drive components with each other. NCP allows you to generate all relevant information and data needed for the drive. The NCP software can be downloaded for free here .

Your benefits at a glance:

- Clear dimensioning - input and output values at a glance

- Free for you

- Offline mode - designing without Internet access and administrator rights

- Easy data entry despite very complex applications

- Shorter data entry times thanks to the extensive database of over 17,000 engines

- Comprehensive technical documentation for all calculation steps

- Credibility based on checking all entered values

- Multilingual service - seven different languages to choose from

- Online access to dimension sheets and CAD files for selected products

For questions and interest in gears, please contact WObit specialists .