Companies are constantly struggling with the challenge of maximizing the productivity of employees during the implementation of tasks, work and also products compatible with human capabilities and their needs. While improving the productivity, while reducing the effort and discomfort of the operator, Texcan's measuring technology is an extremely helpful tool.

Measurement systems Tekscan are used to measure the distribution of force and pressure of various elements and due to their diversity, they are used in many fields of industry.

The basic solution proposed by the Tekscan company, which WObit is the only representative in Poland, is I-Scan system . On the I-Scan measuring system , the scanning electronics consist of Tekscan, software and patented thin-film force sensors

| The electronic part of the entire Tekscan system is the Evolution Handle sensor holder. It enables connecting a foil pressure sensor with a PC via the USB port - this holder has an integrated USB cable. It collects information from the sensor and sends it in digital form to the PC where the software is installed. I-SCAN allowing visualization, archiving and further analysis of results. |

The I-Scan system contains research software based on o Microsoft Windows platform, related equipment and patented sensors from Tekscan. The system is so versatile that it allows copying pressure distribution data and pasting them to other applications (eg MS Excel), saving them as a text file (ASCII) and exporting to other programs, or printing on any compatible printer with Windows.

In addition, this program allows you to record measurements to relevant files, including with * .avi extension, which allow you to post the results of research, among others, in multimedia presentations. Saved files with the extension * .fsx allow you to replay the measurements in the program I -SCAN for further analysis

| The selection of the appropriate sensor depends on the specific application requirements. The Tekscan pressure sensors have a ~ 5 microsecond response time, providing almost instantaneous data transfer. The I-Scan system uses patented thin-film touch sensors strengths of just 0.625 mm, which easily fit into tight spaces. These sensors have the form of a matrix, which is why they are called measuring mats. Each mat is composed of individual measuring points (so-called senseli) - the highest resolution mats have as many as 248 senles per 1 cm. |  |

An improved version of the system I-Scan is the High Speed â??â??I-Scan system, which it supports even faster scanning speeds (up to 20,000 Hz). Sensors used for quick measurements have a smaller density of measuring points, compared to the I-Scan system to process measurement data faster. High Speed â??â??I-Scan is ideally suited for measuring high impact forces, such as in crash tests, as well as for measuring fast production processes.

| Sensors in the form of large mats are part of the BPMS system intended for measurement the distribution of pressure exerted by the human body relative to surfaces such as seats, mattresses, upholstery and backrests. Due to the fact that the measuring mats are extremely thin, they do not exert influence on the measured surface and do not change its characteristics. For this system, the number of senles on the mat is 2016, and its spatial resolution is 1 sensel / cm 2 . |

Similar to BPMS the system is CONFORMat also used among others to optimize sitting, padding and positioning solutions by allowing better surface adaptation. This system uses a new sensor technology that adapts to the complex and deformed support surfaces, such as the seats. It allows you to measure the pressure exactly in those places where it actually occurs. The structure of the sensor prevents its attenuation and causes the sensor to adhere to the surface, which allows obtaining reliable and very accurate measurement data.

| To identify and test the strengths and pressures felt by each finger and finger, Grip system . Such specific measurements are made to improve the product structure, eg various types of gloves, handles or packaging, as well as to improve the efficiency of the employee. Grip system dynamically measures and records the pressure and strength of the hands and fingers exerted during gripping, catching, holding, carrying, lifting and using various elements. The system allows one person to sequentially capture several objects in a different way. Sensors are available in various shapes, are reusable, and also provide precise measurement of force and pressure. |  |

An interesting system dedicated to the tire industry is TireScan . It is widely used to register the pressure exerted on the surface by the tire tread of passenger cars, lorries, agricultural vehicles and even aircraft. Data can be easily registered both static and dynamic. TIreScan system displays real-time, high-resolution color images, showing the pattern of the tire impression.

| The system is very intuitive and, thanks to specific graphs and integrated image analysis, makes it possible to assess the quantity and quality. In a given application, the system can continuously measure the contact area, edge area, longitudinal and latitudinal width as well as the transverse pressure profile. Then TireScan can compare the results of one tire measurement with the other or results measurements for one tire at different load and inflation rates. Thanks to such data, tire designers and manufacturers can analyze the construction of the treadmill, different tire coefficients, and also control the quality and assess the condition of the vehicle suspension. |

The use of a USB interface makes the system portable and easy to use. TireScan can be used with the same ease in a lab, factory or field tests. Sensors can be placed on the road, in the garage, mounted on machine rollers or attached to a mobile test platform. They can even be buried under the ground to test the tire pressure with the ground

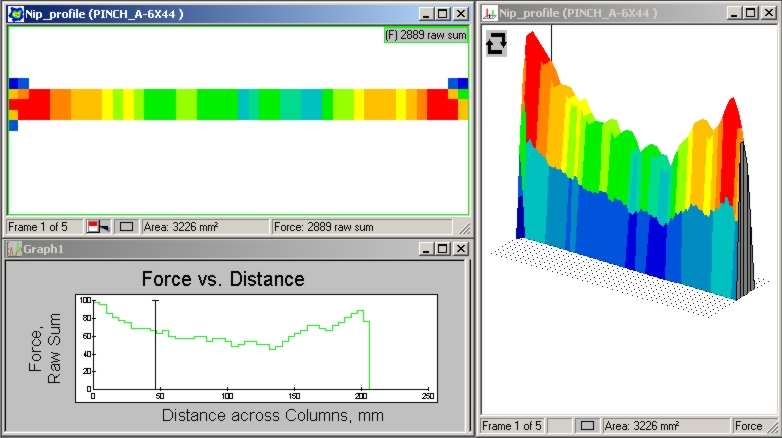

| The automotive industry has also prepared a Wiper system for measuring the pressure between the wiper blade and the windshield. The uniform profile of the wiper blade's pressure force results in perfect visibility. Uneven profile can cause scratches. In the case of too low a force or bulging of the pen, the wiper leaves a dirty glass. Many car windows consist of complex curves, which is a great challenge for windshield wipers. The pen can adhere well in one place / position, while in another it does not. Here, also measurements allow you to test the product and control the quality of its performance |  |

Thanks to the existence of more than 200 sensor models of various sizes and shapes, as well as the support of the highly skilled engineers of Tekscan and WObit, each system can be configured to meet the specific needs of your application.