It is hard to imagine production automation and machine building without actuators ensuring smooth and precise linear movement. Among the many available solutions, it is worth paying attention to MLA linear modules, which are a good alternative to pneumatic and hydraulic drives.

What is a linear module?

MLA linear modules produced by the Polish company WObit constitute acomplete solution for implementing linear movements and are intended primarily for transport and positioning applications. Thanks to the structure based on appropriate aluminum profiles and, as the name suggests, modularity, these products have a very wide range of applications. The family of linear modules consists of several design solutions in which you can choose the length, motor type, control, additional sensors and mounting accessories.

All linear modules, depending on customer requirements, can be driven by a stepper motor with external or integrated electronics, a DC motor and a servo drive. Choosing the right module for the application is made easier via the configurator available at ml.wobit.com.pl.

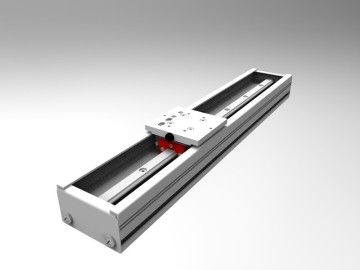

MLA - linear module with belt drive

The first and most popular module is the MLA version, built on a dedicated aluminum profile and a guide with a profile rail on which the trolley rolls, and the drive is transmitted by a toothed belt. In the standard version, the module is driven by a stepper motor, which enables open-loop control (without the need to use a position sensor). At the customer's request, the MLA linear module can be equipped with a DC, BLDC motor, servo or crank enabling manual control. It is suitable for standard applications requiring dynamic linear movement with light loads.

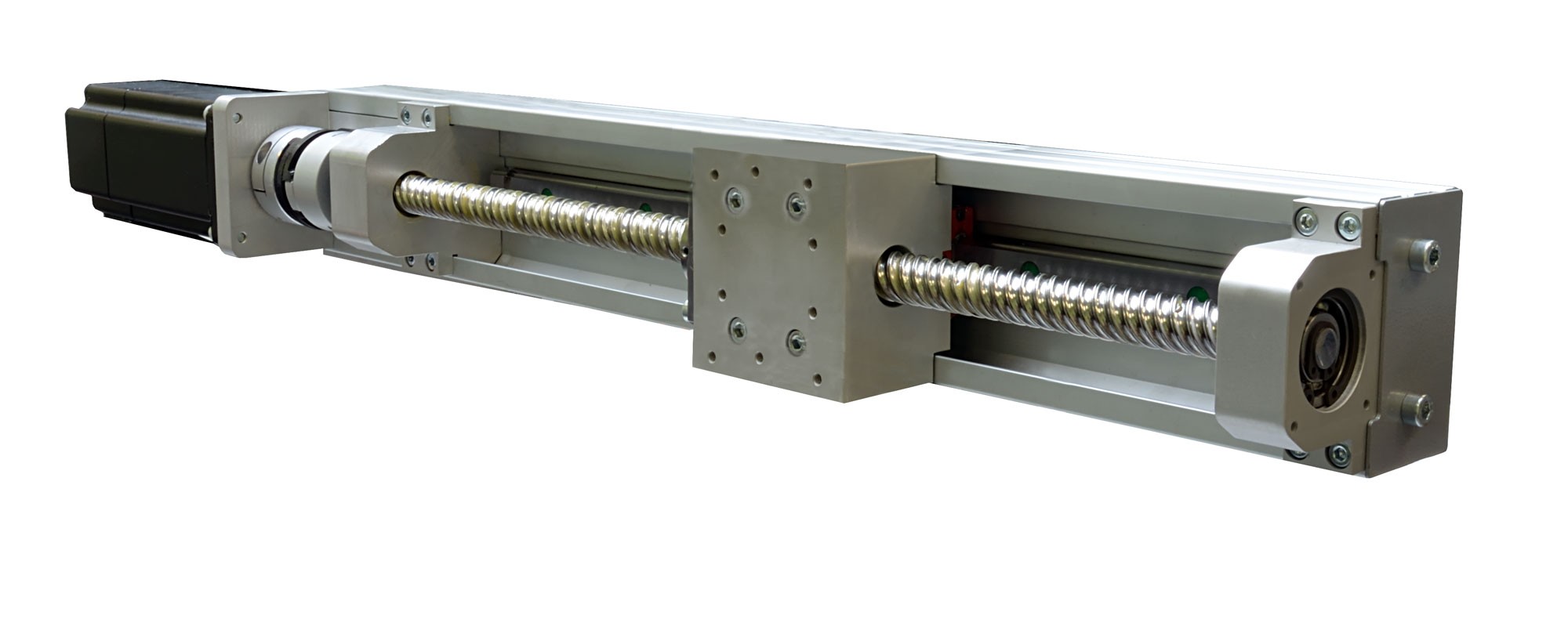

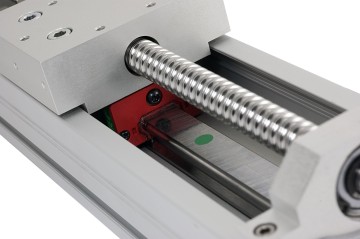

MLAS - linear module with screw drive

In applications requiring higher precision and heavy loads, MLAS linear modules are more often used, the structure of which consists of an aluminum profile, a linear guide and a ball screw. The use of a ball screw allows the transfer of axial forces (up to 1000 N). It also provides high precision of movement, enabling positioning with an accuracy of hundredths of a mm. Similarly to the toothed belt-driven version, MLAS can use a stepper motor, a DC motor, a BLDC motor and a servo drive.

MLA2P - linear module with stiffened construction

MLA2P, i.e. a linear module with a stiffened structure, is also increasingly chosen to carry larger loads. The system is driven by a servo drive with a planetary gear. Rotary motion is converted into linear motion using a toothed belt. Instead of a servo drive with a gear, it is possible to use a stepper, BLDC or DC motor.

The module provides a maximum axial force of up to 500 N and a linear speed of up to 2 m/s, allowing the transfer of up to 50 kg in vertical operation. MLA2P has a maximum range of movement up to 2800 mm and is characterized by compact design and increased resistance to contamination. It is possible to install an encoder and adapt the module to customer requirements.

Applications of linear modules

MLA linear modules are used in transport systems, in the construction of manipulators, measurement systems, pick & place systems, and Cartesian systems.

Thanks to the diversified offer of components and the configurability of MLA linear modules, WObit designers can create non-standard solutions tailored to the needs of a given application. They can be used to prepare both measurement systems and multi-axis executive systems that perform various functions, ranging from assembly and testing of elements, through pick & place operations, to sorting, palletizing and depalletizing of details. The key is to determine the required parameters and select the appropriate product configuration.

Linear modules can be used to build a complete assembly station, e.g. for steel clamps. To build such a system, depending on the load and the required speed of the system, both belt-driven and screw-driven modules in the YZ system, retrofitted with appropriate grippers, can be used. To control the operation of several axes, it is worth using the programmable MIC488 controller. It is used to control up to 4 stepper motors or servo drives in STEP/DIRECTION mode. The controller also allows you to connect incremental encoders for master position control.

In addition to universal inputs/outputs and two 0-10 V inputs, there are also communication ports (RS232, RS485) operating in the MODBUS protocol (slave), allowing communication, e.g. with HMI panels. The free software allows you to easily configure the drive movement trajectory and create programs that control drives, outputs, and respond to input states or communication variable values. Creating motion programs takes place in an intuitive environment via text commands.

It is also worth remembering about a convenient interface between man and machine. The most popular solution is the use of an HMI operator panel. WObit proposes the use of Kinco HMI panels from the Green series. It is characterized by a modern design, excellent user support and an efficient, long-lasting processor.

See our products

MLA-H passive module

MLA-H passive module MLAS16 reinforced version of the module with screw drive

MLAS16 reinforced version of the module with screw drive MLAS-SX Linear module with ball screw with AC servo motor

MLAS-SX Linear module with ball screw with AC servo motor MLA-SIC Linear module with stepper motor with built-in controller + RS485

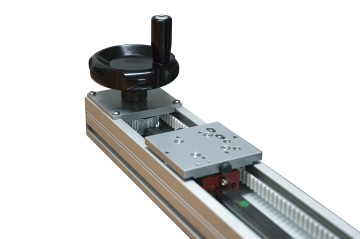

MLA-SIC Linear module with stepper motor with built-in controller + RS485 MLA-R Linear module with manual drive with crank

MLA-R Linear module with manual drive with crank MLA-KX Rope module with stepper motor

MLA-KX Rope module with stepper motor MLA-SX Linear module with servo motor

MLA-SX Linear module with servo motor MLA-SKX Linear module with stepper motor and integrated controller

MLA-SKX Linear module with stepper motor and integrated controller MLAS-KX linear module with ball screw driven by a stepper motor

MLAS-KX linear module with ball screw driven by a stepper motor MLA-DX Linear module with DC motor

MLA-DX Linear module with DC motor MLAS-E passive module

MLAS-E passive module MLAS-DX Linear module with a constant-current motor

MLAS-DX Linear module with a constant-current motor