Precise control of dimensions, geometry and shapes on flat surfaces is a significant challenge for many sensors. The new series of surfaceCONTROL 3D sensors enables precise measurement in applications requiring very high accuracy.

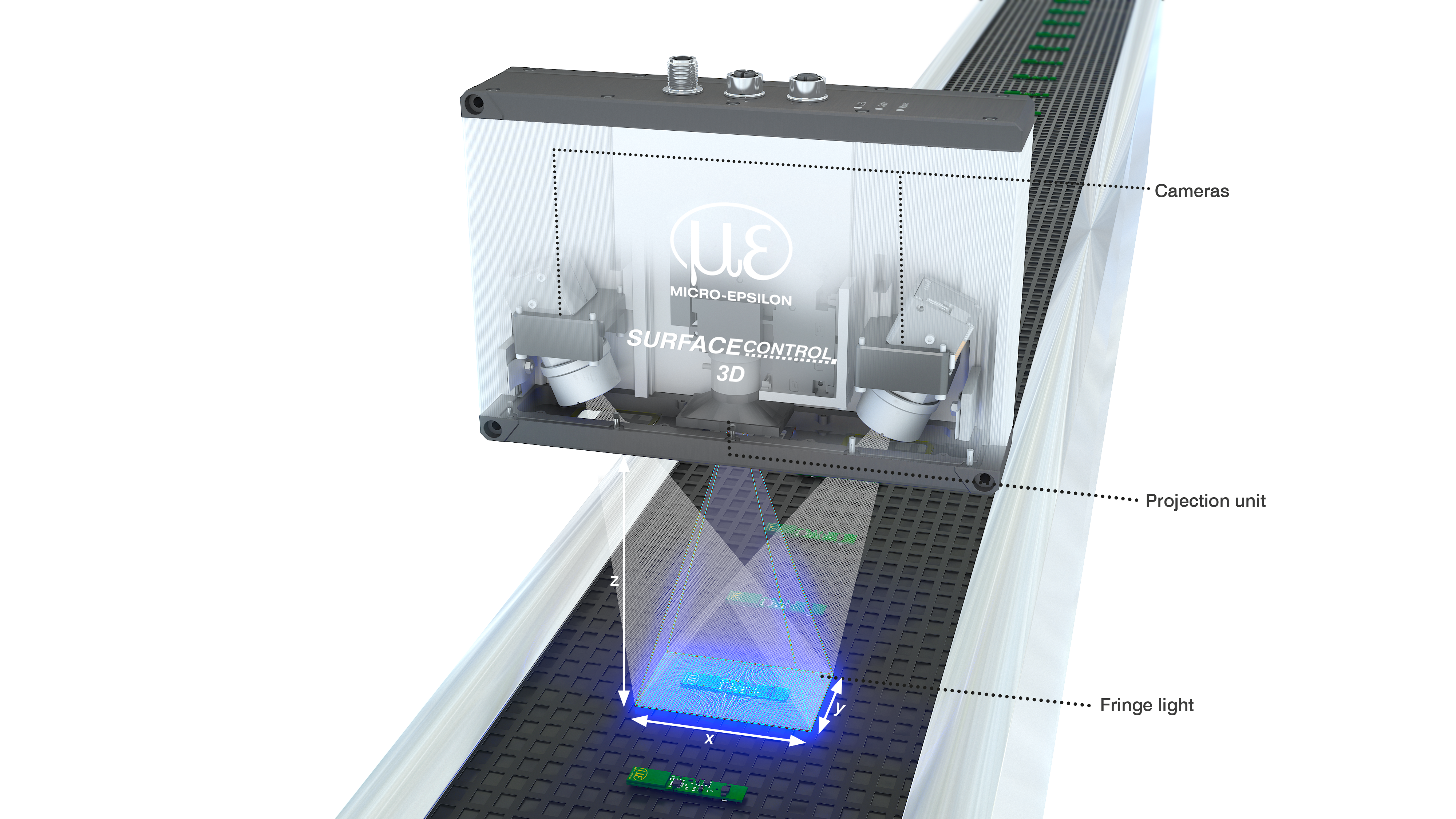

Principle of measurement

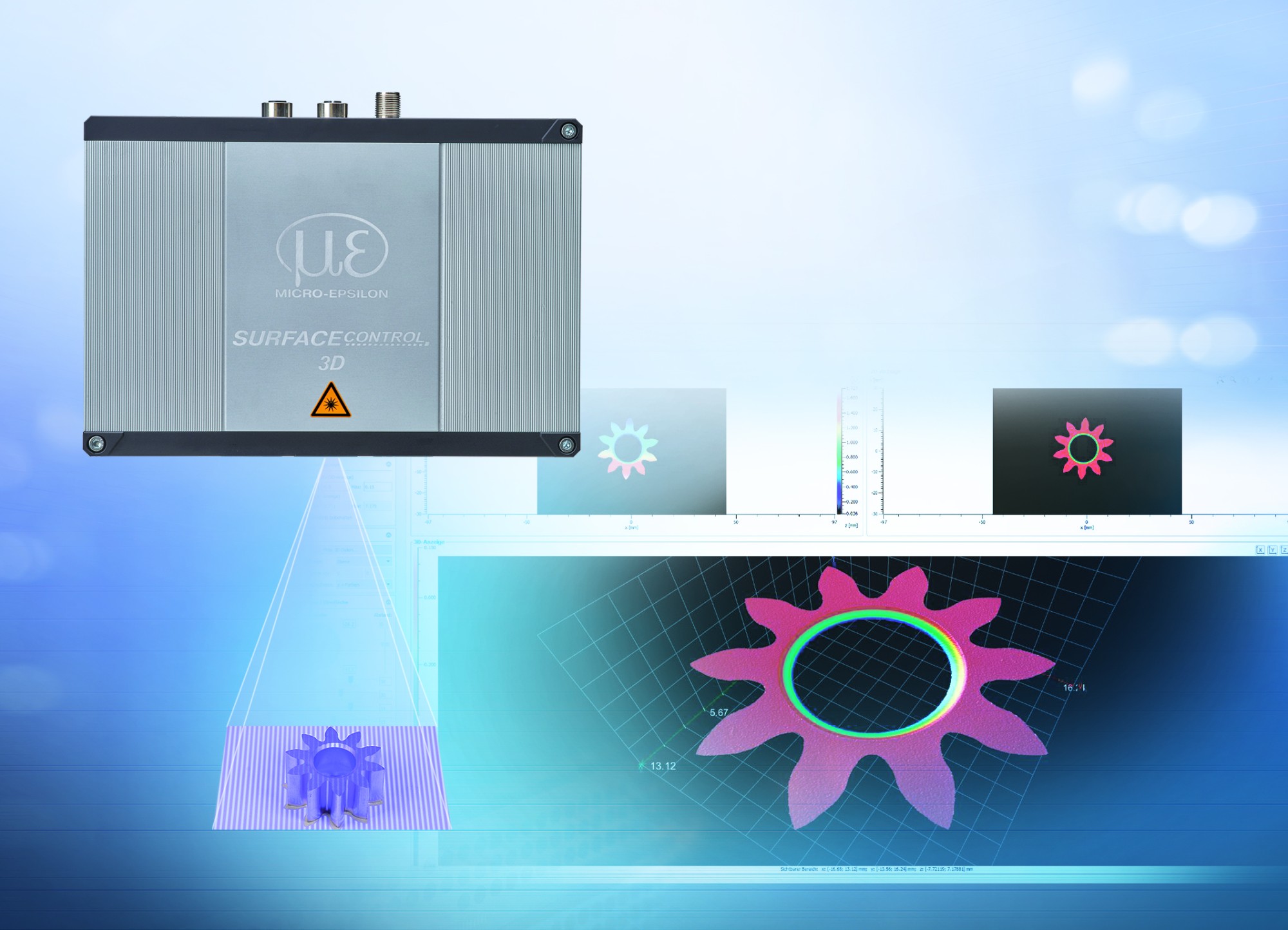

New category of surfaceCONTROL 3D sensors perfect suitable for automated in-line inspection of surfaces, geometries and shapes on surfaces reflecting diffuse light. They work on the principle of optical triangulation based on the projection of light fringes. Using a matrix projector, a sequence of patterns is displayed on the surface of the object being examined. The light of patterns reflected diffusely from the surface of the examined object is recorded by two cameras. The three-dimensional surface of the examined object is then calculated based on the recorded sequence of images and knowledge of the location of the two cameras relative to each other.

The new generation of precise in-line 3D measurements

Among the 3D sensors, it is worth paying attention to the surfaceCONTROL 3D 3500 series, which is distinguished by its compact design and high measurement accuracy combined with high data processing speed. The two models cover different measurement ranges. With repeatability down to 0.4 μm, the sensor sets a new standard in high-precision 3D measurement technology. Therefore, even the smallest flatness deviations and height differences can be reliably detected.

In addition to fast data transfer via Gigabit Ethernet, the sensor offers an additional digital I/O interface. The 2D/3D gateway provides the possibility of connecting EtherNet/IP, PROFINET and EtherCAT. Advanced software tools allow for precise 3D measurements and surface control. GigE Vision compatibility also allows for easy integration with third-party imaging software. A comprehensive SDK for client software integration completes the software package.

3DInspect software for 3D measurement and inspection tasks

The surfaceCONTROL 3D 3500 sensor is equipped with advanced software tools that enable precise 3D measurements and surface control. 3DInspect software is an advanced tool for setting sensor parameters and measurement tasks in industry. This software transmits measurement data from the sensor via Ethernet and delivers it in three-dimensional form. This 3D data is then processed and evaluated using 3DInspect measurement programs on the computer and, if necessary, recorded and transmitted via Ethernet to the control unit. In addition, the software allows you to store 3D data. The 3DInspect software is included in the scope of delivery. For connection to the automation interface, a functional extension of 3DInspect Automation with SC3510 sensors is possible, which also includes comprehensive data logging.

3D View software for 3D visualization

3D View software offers a convenient user interface forsurfaceCONTROL sensors . This easy-to-use software allows you to quickly commission and evaluate your sensor. It offers configuration and optimization of parameters and ensures correct positioning of the measured object and sensor. The software can also be used to start data acquisition. It visualizes the acquired 3D data and exports it in various file formats (ASCII, CSV, STL, PLY) for further processing.

3D View software is particularly useful for system integrators because it provides important information. It gives them access to all GenICam parameters, which greatly simplifies software integration. For in-line applications, displaying the measurement duration allows conclusions to be drawn about the cycle time.

Surface inspection software

In addition to standard programs, Micro-Epsilon has also developed special surfaceCONTROL DefMap3D software for individual surface analysis. It is a comprehensive software solution for detecting and analyzing surface defects. It includes all components and processes required to establish, configure and evaluate inspection tasks.

Many functions equally support the analysis of individual parts, the measurement of small series, as well as the robot-assisted inspection of several measurement fields. Sensor control, 3D point cloud calculation and defect detection can be automated using macro commands.

As part of surface analysis, the software provides several methods for detecting and objectively assessing form errors in surface data. The targeted use of different types of filters can reduce the influence of surface structures (e.g. granularity). A report containing the inspection results is generated. surfaceCONTROL DefMap3D is available in various versions, the scope of which is focused on different measurement tasks.

Applications of the surfaceCONTROL 3D system

Advanced software and high precision allow you to control 3D geometry and detect shapes. These sensors are used for high-precision 3D measurement of mechanical parts. They enable measurement of the distance between holes, flatness and coplanarity of mounting surfaces. For example, they are used to inspect rivets, both for measuring the width, angle of inclination, and position of the rivet. surfaceCONTROL 3D systems are also used to control electronic components. They verify the flatness of precision smartphone center plates, the flatness of hollow PCB substrates, and check the completeness of electronic components on assembled PCBs. surfaceCONTROL sensors monitor the distances and parallelisms in the plane of the mounted elements in relation to each other and to the ground.

The systems discussed are also widely used in the automotive and machinery industries to detect defects and assess the workmanship of details such as clutch discs. The high resolution allows for 3D text recognition and the detection of the smallest structures, including embossing, which cannot be measured using 2D image processing due to the lack of contrast. Please contact our advisors who will help you choose a solution for your application.