What is a precision gear? There is no simple answer to this question. Because when gear manufacturers talk about precision gears, they don't all mean the same thing. Of course, this causes confusion among customers. But is there a standard definition at all? What should users know to find their way in the maze of terminology? Together with Nabtesco, we are shedding some light on this topic.

Precision applications require precision gears. It's clear. The lack of clarity starts when trying to define what precision gears are. Depending on who we ask, the answer will be different. The situation is complicated by inconsistencies in the application of the terms backlash and hysteresis loss. However, these terms are crucial to the definition. So chaos is inevitable.

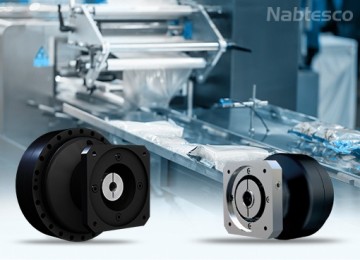

Not all precision gears are created equal

Typically, a hysteresis loss is used to quantify the precision of a gear. Planetary gear manufacturers use a different approach: They use the term backlash. The result is data that makes comparison difficult.

What is meant by precision gearing depends on who you ask:

- Nabtesco (cycloid gears): < 1 arc.min of hysteresis loss

- Planetary gear manufacturers: 1 to 3 arc.min play

- Analysts / Statisticians: < 20 arc min

Basically, it's like comparing apples to oranges because hysteresis loss and backlash are two completely different phenomena. The hysteresis loss is measured through the hysteresis cycle and describes the torsional deflection of the drive shaft when the input shaft is locked with a specified torque (in Nabtesco to rated torque); this reading is taken on the vertical axis. The hysteresis loss consists of purely mechanical backlash and inherent friction in the hysteresis measurement process. Backlash is only part of the overall effect. When looking for a precise transmission, you should therefore look at it closely.

Cycloidal gears are characterized by unparalleled precision

If the backlash of cycloidal gears and planetary gears were compared, the results would be as follows:

- Nabtesco (cycloid gears): 0.1 to 0.3 arcmin backlash

- Planetary gear manufacturers: 1 to 3 arc.min play

The high precision of Nabtesco cycloidal gears is due to their special design. Precision cycloidal gears use eccentrics and rollers to transmit power instead of gears as is the case with planetary gears. Two cycloid discs, which are rotated 180° relative to each other, contact the housing through rollers around its entire circumference. An even distribution of torque is achieved inside the gearbox while the power flow is simultaneously transferred outwards to the housing material. The increase in looseness is minimal even with prolonged use. On the other hand, in planetary gears, the relatively high surface pressure on the gear teeth increases wear, resulting in a significant increase in backlash over the lifetime of the gear.

Precise gears with virtually no backlash

In terms of backlash, precision gears can be divided into three categories: limited backlash, virtually zero backlash and zero backlash. Zero-backlash gears - as the name suggests - have no backlash but exhibit hysteresis loss. Few applications require such high precision. Virtually backlash-free precision gearboxes are an excellent choice for most applications. Nabtesco cycloidal gearboxes are an efficient and economical solution in this regard.

By the way: From a technical point of view, it is possible to convert any type of gearbox into a precision gearbox. Another question is whether it is economically feasible. For example, in the case of worm gears, the cost would be prohibitive.

Do you want to know more about the advantages of precision cycloidal gears? Click here for more information.