In order to precisely determine the changeover time of coils, optoNCDT ILR2250-100 laser distance sensors from Micro-Epsilon continuously detect the coil diameter with highest precision. They can also be used in harsh industrial environments for measurements of challenging surfaces.

Steel strip coils are mainly used in the processing industry, such as the automotive industry to transport wide flat products made of metal or alloys. Large dimensions of around 1.8 m in diameter and the enormous weight of the coil are still challenging for manufacturers.

In order to be able to process the material further, the coils must be unwound. For this purpose, continuous detection of the diameter is necessary in order to monitor the uncoiling process precisely and to determine the changeover time of the coil at an early stage.

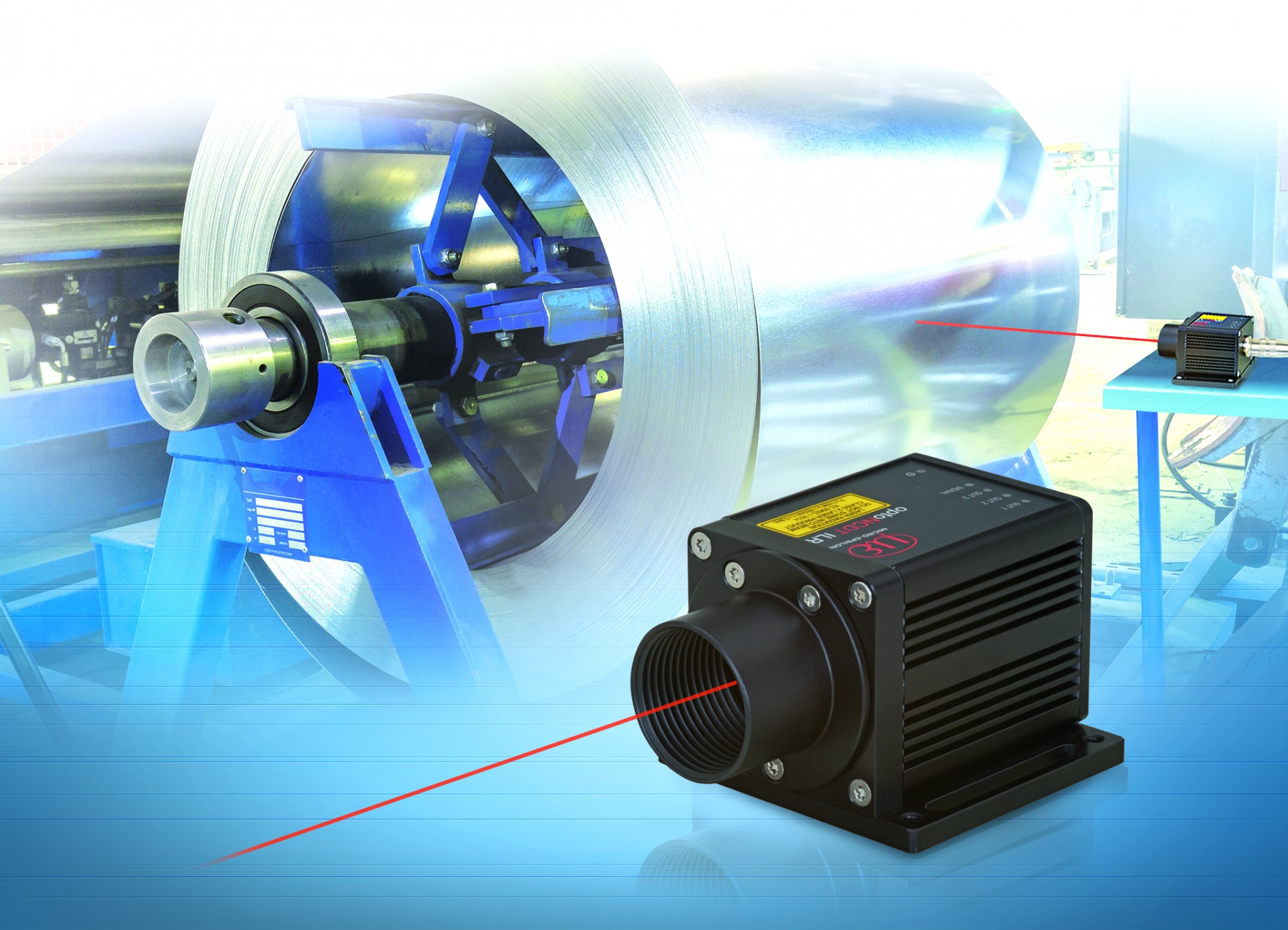

optoNCDT ILR2250-100 laser distance sensors from Micro-Epsilon measure the coils according to the phase comparison method. For this measurement task, a sensor is mounted at a distance of up to 10 m aligned to the radius of the coil. It continuously measures the distance to the coil. Unwinding the coil continuously reduces the diameter. Consequently, the distance between coil and sensor increases. The sensor reliably detects this change in distance and transmits the measurement values to the control system involved in the production process. Compared to conventional estimated calculations based on the rotation of the coiler or strip length measurements using mechanical wheels, this method allows precise and wear-free control of the production process.

The laser distance sensors from Micro-Epsilon enable direct, continuous and wear-free measurement of the coil diameter. The ILR2250 sensors overcome both harsh environmental conditions and challenging surfaces of polished and matt metals.